The polishing process refers to applying a layer of colorless and transparent varnish on the surface of the label, with the aim of increasing the glossiness of the printed material, achieving the functions of preventing stains, moisture, and protecting graphics and text. In general, the polishing process can be divided into overall polishing, partial polishing, reverse polishing, etc. In this article, the author mainly elaborates on the three types of polishing processes mentioned above, and deeply analyzes their characteristics and usage precautions.

Overall polishing

Overall polishing characteristics

Overall polishing, also known as full plate polishing, is the process of applying a layer of colorless and transparent varnish to the entire label surface. After leveling, drying, calendering, and curing, a thin and uniform transparent glossy layer is formed on the label surface, which enhances the smoothness of the label surface and adds decoration and processing to printed text and images.

It should be noted that there is a certain difference between overall polishing and laminating. Laminating refers to the process of covering a layer of transparent plastic film with a thickness of 0.012-0.020mm on the surface of the label after printing, by heating or pressure of the laminating machine, so that the label is overlaid with the plastic film. The pre coated film material that requires heating for lamination is shown in Figure 1 (left), and the thin film material that requires pressure lamination is shown in Figure 1 (right).

Figure 1

Figure 1

Because the laminating process requires the use of plastic film as a raw material, from an environmental perspective, the polishing process is more environmentally friendly than the laminating process, especially water-based polishing and UV polishing. Water based varnish has the characteristics of non toxicity, non irritation, no organic volatile compounds, low cost, and wide material sources. At the same time, it has high transparency and good glossiness. Under long-term strong sunlight exposure, water-based varnish is not easily yellowed, has strong wear resistance, and is scratch resistant. UV varnish contains almost no solvents, and the energy consumption required for curing is relatively low; Strong affinity for ink and firm adhesion; The printed surface has better wear resistance, chemical resistance, and chemical resistance, with good stability, and can be cleaned with water and ethanol. In short, UV coated products are not easy to stick together and can be stacked and stacked after curing, greatly saving time and improving production efficiency for the next process.

Precautions for overall polishing

When using the overall polishing process to increase the glossiness of the label, in order to ensure the quality of the polishing and ensure the normal operation of production, the following four aspects need to be paid attention to: first, control the thickness of the gloss oil; The second is to make a good choice of varnish, because there are many types of varnish, so it is necessary to choose the appropriate varnish based on the type of printing material and the different polishing methods; The third is to control the viscosity and surface tension of the varnish. The viscosity of the varnish has an impact on its leveling, drying speed, surface glossiness, etc. Therefore, it is necessary to adjust the appropriate viscosity of the varnish according to different printing materials. At the same time, attention should be paid to the changes in the surface tension of the varnish, so that the surface tension of the varnish is lower than that of the ink layer. Only in this way can the varnish wet, adhere, and soak the surface of the label well; The fourth is to pay attention to the coordination between the polishing speed, coating amount, pressure, and curing equipment power. The relationship between them should be adjusted reasonably according to the wetting and absorption of the varnish on different substrate surfaces.

Spot Varnish

Local polishing characteristics

Localized polishing refers to applying gloss oil only to a prominent position in the label, making it appear brighter, more vivid, and more three-dimensional compared to the surrounding text and images, thereby producing a unique artistic effect. At present, common local polishing processes include local gloss oil, local matte oil, local snowflakes, local sanding, local foaming, local refraction, local wrinkles, etc.

Partial glazing can be implemented after lamination or directly on printed materials. However, in order to highlight the effect of partial glazing, it is usually done after lamination on printed materials, with matte coating being the most common (accounting for about 65% of partial glazing products). As shown in Figure 2, there is a partial gloss effect on the label.Localized polishing refers to applying gloss oil only to a prominent position in the label, making it appear brighter, more vivid, and more three-dimensional compared to the surrounding text and images, thereby producing a unique artistic effect. At present, common local polishing processes include local gloss oil, local matte oil, local snowflakes, local sanding, local foaming, local refraction, local wrinkles, etc.

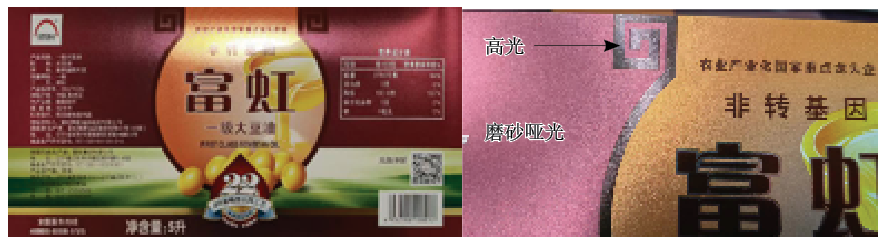

Partial glazing can be implemented after lamination or directly on printed materials. However, in order to highlight the effect of partial glazing, it is usually done after lamination on printed materials, with matte coating being the most common (accounting for about 65% of partial glazing products). As shown in Figure 2, there is a partial gloss effect on the label.

Figure 2

From this, it can be seen that the surface of the label after local polishing treatment has a more textured and three-dimensional feel, resulting in higher brightness, transparency, and wear resistance in the local area of the label, giving a strong visual impact.

Precautions for local polishing

Partial polishing can be achieved through methods such as screen printing and flexographic printing. Because the ink layer of screen printing is thicker than that of offset printing, gravure printing, and embossed printing, using screen printing for local polishing will have a more obvious effect. However, when using screen printing for local polishing, the following aspects should be noted:

One reason is that the formula of UV varnish is different in winter and summer. When using it, attention should be paid to distinguishing the changes in season and weather temperature, and choosing the appropriate varnish. Generally, the curing content of UV varnish in winter is lower than that in summer. If the formula of winter UV varnish is used in summer, it will cause incomplete curing of UV varnish, which can easily lead to problems such as anti sticking. Conversely, if the formula of summer UV varnish is used in winter, it will cause poor leveling of UV varnish, resulting in problems such as foaming and skin formation.

Secondly, UV varnish should be thoroughly stirred before use, as it is composed of many chemical raw materials. If left unused for a long time, the chemical raw materials in the varnish part of the bucket will separate, causing layering. Therefore, it is necessary to stir thoroughly before use.

Reverse polishing

Reverse polishing characteristics

Reverse polishing is a polishing mode that combines local polishing and local sanding to achieve high contrast effects in local graphics and text. The reverse polishing process can be completed in one go on a printing machine or offline.

Reverse polishing can create a contrast effect between the high gloss mirror surface and the matte frosted surface on the label surface, creating a stronger contrast in brightness. It can not only achieve anti-counterfeiting effect, but also achieve aesthetic effect. Reverse polishing first uses offset printing to print transparent frosted base oil on non high gloss positions on the design draft, and then applies surface oil to the label printed product in a full plate manner and solidifies and dries. The surface oil reacts with the first printed base oil to form a frosted matte effect on non high gloss areas, while the areas without base oil form a high gloss effect. Due to the use of offset printing in non highlight positions, the overprinting will be very accurate, ensuring the printing accuracy of graphics and text in highlight positions.

Fig 3

Figure 4

As shown in Figures 3 and 4, the label products are produced using reverse polishing technology. Among them, the right image in Figure 4 shows the enlarged effect of the label, and the bright and matte areas are marked in the diagram. The red printed area in Figure 5 has a glossy effect, while the white and blue areas have a matte finish.

Precautions for reverse polishing

When using the reverse polishing process, it is important to ensure that the ink used for regular graphic and textual printing of label products has been thoroughly dried or cured. If the ink layer is not dry, it will result in incomplete curing of the varnish and no comparative effect; Secondly, when designing documents, do not choose small fonts and patterns for reverse gloss effect. If the font or pattern is too small, it will cause paste problems; The thickness of the frosted texture is related to factors such as the speed of the printing machine, printing pressure, varnish thickness, varnish type, and the flatness of the substrate surface. If the printing machine is fast, the oil layer is thin, the frosted texture is rough, and the surface flatness of the printing material is good, the effect of frosted texture will be very obvious.

In general, reverse polishing can achieve contrast effects that ordinary polishing cannot achieve, making the printing effect of printed products more exquisite, playing the finishing touch, and elevating the quality of label printing to a higher level.

Faced with increasingly strict environmental protection and pollution prevention requirements from the country, as well as consumers' preference for bright and novel appearance of printed products, in the fiercely competitive market environment, more and more label printing companies are beginning to use various post press finishing processes on labels, especially glazing processes. Through small changes in post press finishing processes, product design diversification is promoted to adapt to new environments, meet new needs, and add stronger visual impact to label products.