5 Anti-Counterfeiting Techniques That Leave Fake Liquor Nowhere to Hide

As a special category in the consumer goods market that combines social attributes with high added value, the Baijiu industry has long faced severe anti-counterfeiting challenges. As a result, Baijiu labels have become the most technically intensive and innovative submarket in the entire label printing field, and are regarded as the 'high ground' of anti-counterfeiting technology.

Today, Baijiu labels, in addition to serving packaging and decorative purposes, have become a line of defense against counterfeiting that integrates traditional technologies and cutting-edge innovations such as materials, design, processes, and digital traceability. They represent the highest level of complexity currently achievable in the label printing industry. In the following, I will analyze in three articles the mainstream anti-counterfeiting technologies in Baijiu labels, the technical analysis of typical application cases, and the future development directions of Baijiu labels, exploring how they achieve a balance between craftsmanship presentation and security assurance.

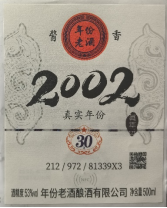

Because Baijiu labels vary depending on the quality level of the liquor, the anti-counterfeiting technologies used also differ based on practical needs and cost considerations. In this article, the author has collected and analyzed Baijiu labels ranging in price from tens to hundreds of yuan, focusing mainly on the following five anti-counterfeiting technologies.

01

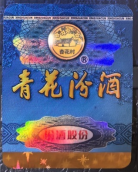

Physical Anti-Counterfeiting

Physical anti-counterfeiting technology, also known as raw and auxiliary materials anti-counterfeiting technology, mainly includes anti-counterfeiting substrate materials and anti-counterfeiting inks. Anti-counterfeiting substrate materials come in a variety of types, such as watermark paper, security thread paper, securities paper, laser holographic materials, and quick-break papers, while there are also many types of anti-counterfeiting inks, including ultraviolet fluorescent ink, infrared non-absorbent ink, thermochromic ink, and optically variable ink.

In general, the anti-counterfeiting technology of printing materials is relatively straightforward and can be recognized with the naked eye, whereas most anti-counterfeiting ink technologies require the use of specialized detection instruments for identification, making them a secondary-level technology.

02

Design-Based Anti-Counterfeiting

Design-based anti-counterfeiting mainly involves using anti-counterfeiting design software to create graphics and text that are difficult to replicate, such as backgrounds, rosettes, latent images, and line-breaking patterns, so that the original document cannot be used directly through scanning. Labels designed with anti-counterfeiting software are often not printed using four-color halftone printing, but rather use line-based special-color printing without halftones, which cannot be reproduced through scanning and color separation techniques.

It should be noted that because wine labels need to serve both decorative and anti-counterfeiting functions, not all wine labels use spot-color printing. Many labels use more halftone overlays and combination printing to highlight decorative effects.

03

Process-Based Anti-Counterfeiting

Different printing equipment and process combinations can produce different anti-counterfeiting printing effects, such as peel-off backing, glue-surface printing, scratch-off coatings, precisely positioned hot-stamped 'cat's eye' effects, colorful glitter, and multi-color overlays.

Common printing methods used for anti-counterfeit labels on alcoholic beverages include embossing, flexography, screen printing, and digital printing. In particular, the increasingly open and combinable functions of flexographic and digital printing equipment provide more creative space for label design and further increase the difficulty of counterfeiting.

04

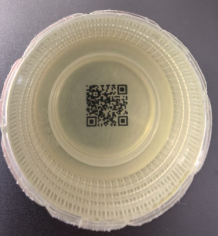

QR Code Anti-Counterfeit

QR code anti-counterfeit technology is the most widely used anti-counterfeit method for liquor labels. A bottle of liquor usually has both a box label and a bottle label, and these labels all contain QR codes that are interconnected. Additionally, many liquor bottle caps have QR codes on both the inside and outside, serving both verification and marketing purposes. These QR codes can be single-color black or multi-colored, and they use encryption technology to identify the product, with a unique QR code assigned to each item. Multi-colored QR codes combine various anti-counterfeit technologies, such as color information of the anti-counterfeit code and material characteristics, achieving triple or even multiple layers of anti-counterfeit protection, making the labels much harder to forge or replicate.

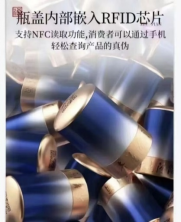

05RFID & NFC Anti-Counterfeiting

Although RFID and NFC are both classified as radio frequency tags, there are still differences between them. RFID is essentially an identification technology, whereas NFC is a communication technology. RFID can only achieve information reading and verification, while NFC technology can enable information exchange. NFC tags can be read by smartphones, tablets, and other devices, whereas RFID tags must be read by specialized readers.

Baijiu labels often use NFC technology, and any phone with NFC functionality can read them at any time, which is very convenient. Some baijiu labels even use both NFC and QR code technology, allowing partial verification of product information. This is not only convenient but also enables multiple anti-counterfeiting features.