28 dynamic images! That's how cans are made!

In daily life, there are various types of beverages that can meet the taste buds of different groups of people. Among these drinks, beer and carbonated drinks have always been far ahead in sales. It is not difficult to observe that these two types of drinks are often packaged and sold in cans on the market. It is also because of the popularity of these two types of drinks that cans have spread all over the world. And it is this can that can be seen everywhere in our daily lives, but its small body hides great wisdom.

background

In 1940, stainless steel cans of beer began to be sold in Europe and America, and the emergence of aluminum cans during the same period also marked a leap in canning technology. In 1963, the can was invented in the United States, inheriting the design characteristics of traditional can shapes and featuring an easy pull tab at the top. In 1980, the European and American markets mostly adopted this aluminum can as a packaging form for beer and carbonated beverages. The manufacturing technology of cans has gradually been updated and improved over time, but this invention has been used until now, and its practicality is evident.

The common aluminum can nowadays consists of a can body and a can lid, also known as a "two-piece can". Among them, the bottom and sides of the tank are connected together to form the same part, while the lid and body of the tank are rolled together without seams or welding.

Production process

01/Aluminum plate preparation

Select aluminum alloy coil with a thickness of about 0.27-0.33mm and a width of 1.6-2.2m, open the rolled aluminum plate through an unwinding machine, and apply a thin lubricant through a lubrication machine for subsequent processing.

02/Round cup punching die

Thin aluminum strips are punched into round cups by a cup punching machine, which is similar to a punch press. The upper die works together with the lower die under machine pressure to press through the aluminum sheet while punching.

03/Tank Forming

► Deep drawing

The stamped round cup is pulled into the shape of a regular high aluminum can by a stretching machine.

29/1000

Reference Knowledge 29/1000 Reference Knowledge 29/1000 Translation Machine Translation: The slender aluminum can in the general field continues to be pulled deep, causing the side walls of the aluminum can to become thinner, ultimately forming a tall and thin can body. Translation Machine · General Field The elongated aluminum can continues to be deep drawn, thinning the side walls of the aluminum can and ultimately forming a tall and thin can body.

划译

机翻 · 通用领域

The elongated aluminum can continues to be deep drawn, thinning the side walls of the aluminum can and ultimately forming a tall and thin can body.

In industry, the deep drawing operation is usually completed in one go through several molds with gradually decreasing sizes.

►Bottom concave stamping and upper edge cutting

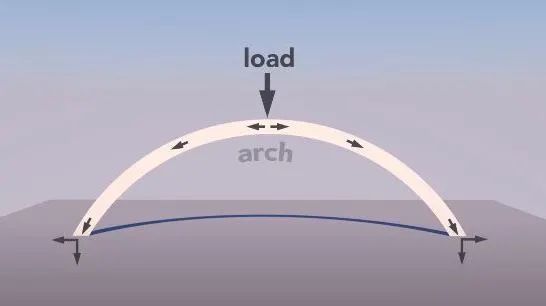

The bottom of commonly purchased soda cans usually has a concave design, mainly to disperse the gas pressure of carbonated beverages to the side, making the can body less likely to expand or burst.

The concave processing is mainly completed by stamping with a dome tool.

Afterwards, it is necessary to cut the uneven upper edge after deep drawing.

04/Cleaning and rinsing

Clean and rinse the aluminum can downwards. When cleaning and rinsing, it is necessary to clean both the oil stains and residues on the surface of the aluminum sheet during stamping to ensure that the hygiene and safety standards of the aluminum can are met. The main steps of cleaning and rinsing include cleaning the oxide film on the surface of the aluminum can with hydrofluoric acid at 60 ℃ and rinsing with neutral deionized water at 60 ℃.

After cleaning, send it to the dryer to dry the surface moisture.

05/Tank printing

Firstly, apply a layer of clear varnish to prevent aluminum from being rapidly oxidized in the air. Then, printing is performed on the surface of the aluminum can, usually using curved printing (also known as dry offset printing). After printing, apply another layer of clear varnish to protect the printing surface.

Next, the aluminum can is quickly passed through an oven to solidify the ink and dry the varnish.

Finally, spray a compound paint on the inner wall of the aluminum can to form a protective film to prevent the aluminum from being corroded by carbonated beverages, while ensuring that the beverage does not have a metallic taste.

06/Cankou necking

The necking of the can mouth is also achieved through a punching die. Usually, a necking machine is used to shrink the aluminum can, generating a "neck" with a diameter of 5 centimeters. The process may seem rapid, but in reality, it requires 11 steps, with each force applied only slightly, in order to gently and gradually shape the neck.

In order to tightly connect the top of the aluminum can to the pull tab cover in the future, the edge of the top must be raised to a slightly flat position.

07/Quality Inspection

Through the rigorous coordination of cameras and high-speed airflow, unqualified cans are removed one by one to ensure the high quality of cans.

08/Capping molding

Coil cleaning: Select coils made of alloys such as 5182 and clean them first to remove surface oil stains and impurities.

Punching and edging: Use a punch press to punch the coil into the shape of a can lid and perform edging treatment to make the edge of the can lid smooth, facilitating sealing and opening.

Painting: Apply a layer of paint on the surface of the can lid to enhance its corrosion resistance and aesthetics, and dry it after painting.

Ring combination: The ring made of 5052 alloy is combined with the can lid to form rivets through processing. The outer ring is then riveted tightly and marked to form a complete can lid.

09/Filling beverages

The can factory is only responsible for making uncovered cans, and the remaining "beverage filling" and "can body sealing" processes must be completed by the beverage company. Before filling, the aluminum can needs to be washed and dried before filling with beverages and bubbles

10/Tank sealing

The automation level of beverage filling factories is very high, usually requiring only one person to be responsible for placing bottle caps on the conveyor pipeline, and the machine can automatically place the bottle caps one by one on the bottle body.

Using a specialized sealing machine for rolling and sealing, the can body and lid are curled together, and then compressed to form tightly overlapping rolled edges (also known as "double rolled edges"), preventing air from entering and leaving.

After so many steps, the production of the can has been completed. Isn't it amazing that a small can has so much knowledge?