How to successfully pass the C9 evaluation? Indian companies need to master these key points of on-site control technology!

Currently, many domestic book and magazine printing enterprises have passed the C9 evaluation of the China Academy of Printing Science and Technology. According to the requirements of C9 evaluation, companies that have passed the evaluation must submit a sample of C9 quality stability evaluation at the end of each quarter. Due to the fact that whether the C9 quality stability evaluation can meet the standards involves the validity of the C9 certificate and whether it can be renewed normally in the coming year, enterprises must attach great importance to it.

Due to the lack of PresSSIGN scoring software in many enterprises, printing control can only be controlled and data analyzed through single point measurement using a spectrophotometer. The author shares the technical points of on-site control for C9 quality stability evaluation based on practical experience in providing C9 technical guidance to multiple enterprises.

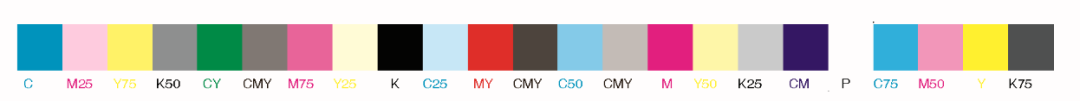

The C9 quality stability evaluation is completed by evaluating the information related to the C9 measurement and control strip, as shown in Figure 1. The C9 quality stability evaluation requires printing companies to add C9 measurement and control strips on printed products, which can be placed at the bite or drag of the layout.

Figure 1 C9 Measurement and Control Strip

Figure 1 C9 Measurement and Control Strip

C9 Quality Stability Evaluation Measurement and Control Strip

The C9 measurement and control strip consists of multiple measurement and control units, including color data evaluation section, star logo, small dot restoration evaluation section, ink uniformity evaluation section, overlay evaluation section, gray balance visual evaluation section, enterprise information, etc.

01

Color data evaluation section

As shown in Figure 2, the color data evaluation section is the most important part of the measurement and control strip, consisting of three sections. The evaluation results are measured and divided by the PressSIGN software, and the lowest score is taken as the quality stability score. A score below 80 points is considered unqualified.

Figure 2 Color Data Evaluation Segment

02

Star logo, small network restoration, and grey balance visual evaluation section

The C9 measurement and control strip places measurement and control blocks such as overprinting, star marking, small dot restoration control, and visual evaluation of gray balance in one measurement and control section, as shown in Figure 3.

Figure 3 Measurement and Control Section

Figure 3 Measurement and Control Section

Star markers are used to visually determine the presence of dot deformation and ghosting. The restoration control section of small branches mainly depends on whether 2% and 98% of branches can be restored normally. Due to the inclusion of grey balance evaluation in the color data evaluation section, the grey balance visual evaluation section has little effect in this measurement and control section.

03

Ink color uniformity evaluation section

In the C9 quality stability evaluation, it is required that the maximum axial deviation of the solid density of each color ink should be less than 0.1. Therefore, two four-color solid block evaluation sections are still set up in the quality stability evaluation. Adding solid color blocks from the 3 color data evaluation segments, each primary color has 5 areas in the axial direction for axial ink color uniformity evaluation.

In addition to the measurement and control section for printing quality evaluation mentioned above, the measurement and control strip also includes a QR code containing information such as the company name and time.

data analysis

The analysis and judgment of the star markers, small dot restoration, density uniformity, and other measurement and control segments in C9 measurement and control strips are relatively simple. This article will not repeat them, but will focus on the data and control methods of the color data evaluation segment.

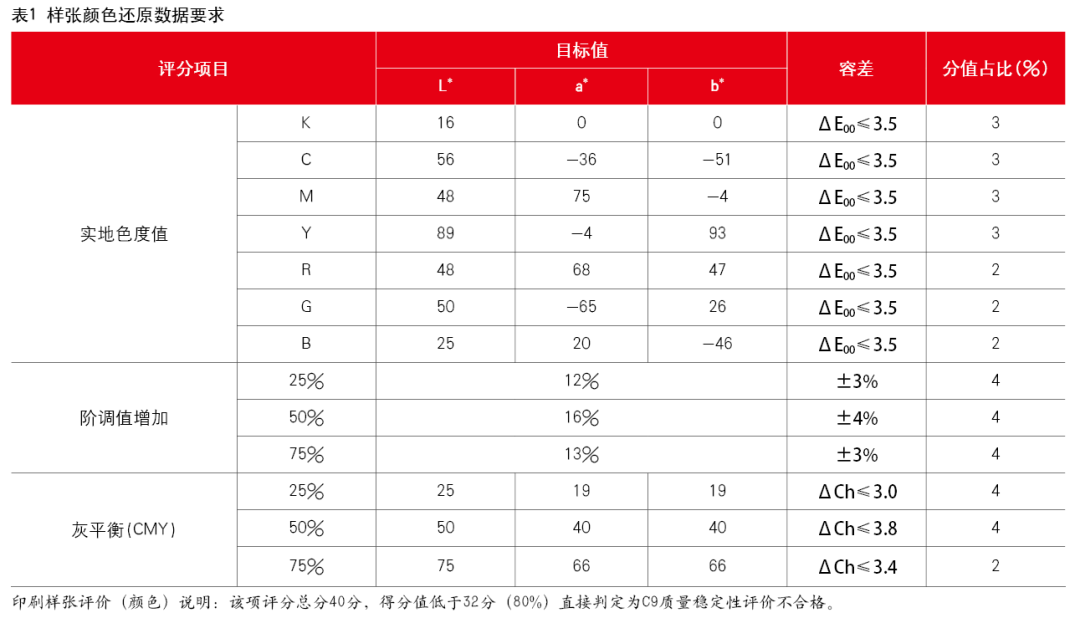

In the C9 quality stability evaluation, the requirements for color reproduction data of the sample were proposed as shown in Table 1. The color data evaluation section consists of three parts, namely the target chromaticity values and color difference requirements for seven solid colors, the target and tolerance for tone increment, and the gray balance chromaticity difference.

01Actual chromaticity value

The actual chromaticity value of primary color ink is not only related to the ink pigment formula, but also affected by the paper color and ink layer thickness (actual density). The chromaticity values of R, G, and B secondary colors are further affected by ink overprinting. The chromaticity value of ink on the ground will vary depending on the combination of printing materials. Therefore, the actual chromaticity value of ink on the ground should be judged by actual measurement during machine printing to determine whether it meets the standard.

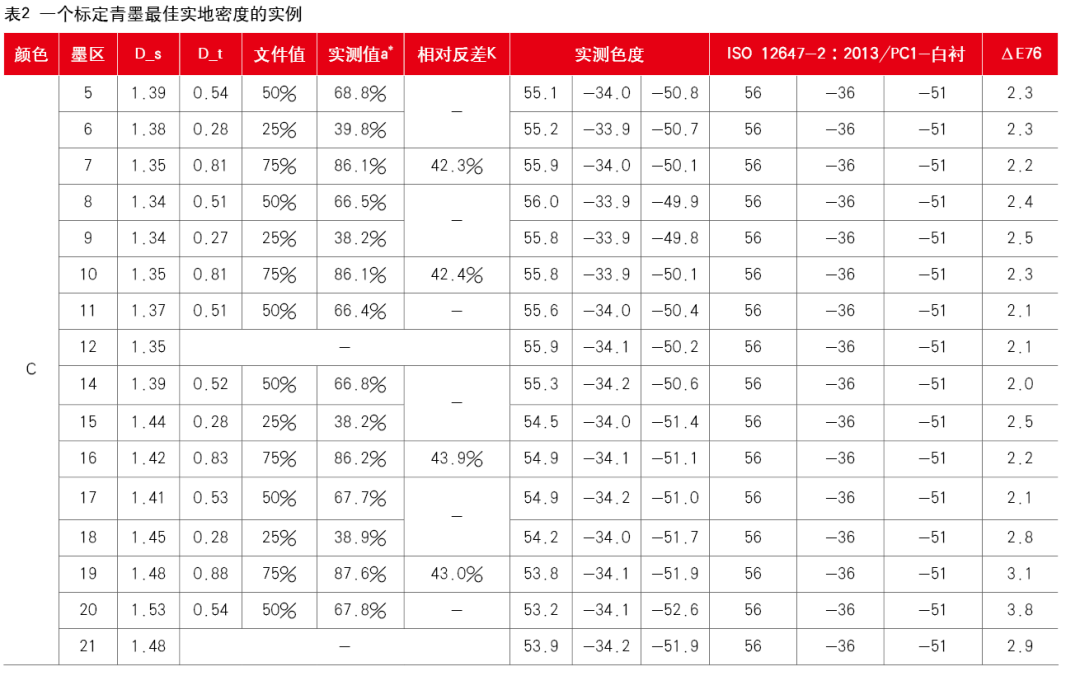

In addition, using chromaticity data to determine ink volume in printing control is not intuitive enough. Density is still commonly used for production control, but it is necessary to first test and calibrate the optimal solid density for the production paper and ink combination. When testing the optimal solid density under production conditions, C, M, Y, K solid and secondary color blocks (R, G, B) can be printed with different ink amounts. The Lab values of C, M, Y, K at different densities are measured and the color difference between them and the standard value is calculated. The solid density corresponding to the minimum color difference is the optimal solid density for that color.

Table 2 shows an example of calibrating the optimal solid density of green ink. The data shows that the color difference is the smallest when the solid density of green ink is 1.39, and the color difference increases when the density is higher or lower. Therefore, the optimal solid density of green ink for the paper and ink combination in this example is 1.39. If an ink cannot meet the color difference requirements of C9 quality stability evaluation for solid color regardless of density, the ink can only be replaced and tested again.

After calibrating the optimal field density for each color, ink only needs to be added according to the density size in production, which will be intuitive and simple.

02

Gradient increase value (dot increase rate)

The incremental value of gradient is usually referred to as the dot growth rate. The factors that affect the dot enlargement rate in traditional offset printing include printing environment, equipment status, ink, dampening solution, printing pressure, rubber blanket, backing, ink layer thickness, etc., which are difficult to accurately control. Therefore, there will be differences in the dot enlargement rate between different machines and between different color groups of the same machine.

The thicker the ink layer, the greater the dot enlargement rate, and vice versa. In printing production, the thickness of the ink layer is generally changed by adjusting the ink supply, thereby affecting the depth of the tone. However, the range of ink volume variation is limited. When the ink volume reaches the tolerance boundary, the dot enlargement rate still cannot meet the requirements. At this time, it is necessary to adjust the CTP publishing curve to adjust the dot enlargement rate. This is the reason why printing compensation curves are commonly used in publishing process software.

The C9 quality stability evaluation specifies the target and tolerance range for network expansion rate, and it is easy to determine whether it meets the requirements through simple measurement.

03

Grey balance chromaticity difference

Gray balance chromaticity difference is a difficult point in color data restoration control, for two reasons: firstly, gray balance is the result of the combined effect of ink solid chromaticity value and dot enlargement rate. In control, it is necessary to balance the achievement of solid chromaticity value and tone increase value separately, while also coordinating the relationship between solid chromaticity value and tone increase value. The control method is more complex; The second is to master the method of determining the direction of adjusting the field density and tone increase value through Lab chromaticity deviation. If you are not familiar with the meaning of Lab, it will greatly increase the difficulty of judgment and processing.

04

The meaning of Lab

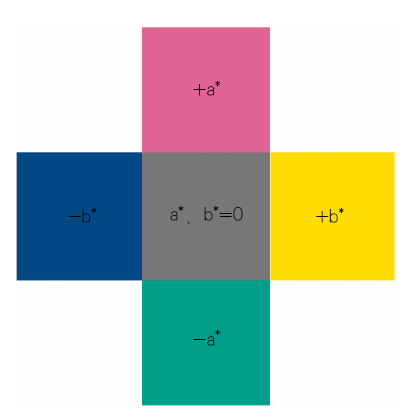

The L * value represents the brightness of a color, and the formula for calculating chromaticity difference does not include the L * value, so it can be ignored; There are positive and negative values for a * and b *. When a * is positive, it represents red; when a * is negative, it represents green; when b * is positive, it represents yellow; and when b * is negative, it represents blue purple. The absolute values of a * and b * can be understood as the saturation of the color they represent. The larger the absolute value, the more saturated the color is. When a * and b * values are 0, it is represented as gray. The hue of red, green, yellow, and blue represented by a * and b * values can be seen in Figure 4. From Figure 4, it can be seen that+a * is a slightly yellowish magenta color, - a * is a slightly greenish green color,+b * is a bright yellow color, and - b * is a blue color with larger shades of cyan and smaller shades of magenta.

Figure 4 Hue situation

05

Definition of chromaticity difference

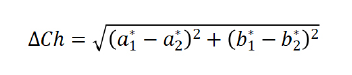

Assuming the measured gray balance color blocks are a * 1 and b * 1, and the gray balance target values are a * 2 and b * 2, the chromaticity difference is Δ Ch.

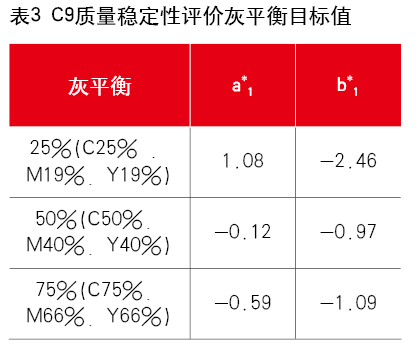

The gray balance target values a * 1 and b * 1 for the current C9 quality stability evaluation are shown in Table 3.

C9 Quality Stability Sample Printing Site Control Method

When printing C9 quality stability samples, the actual chromaticity value, tone increase value, and gray balance chromaticity difference must all meet the standards. Among them, the actual color value is directly related to the ink volume, and can be controlled according to the optimal actual density and its tolerance range. After the printing plate is installed, the ink volume can only be adjusted slightly to adjust the dot enlargement rate to a limited extent. The grey balance is related to both the actual chromaticity and the increase rate of network points, and it is necessary to coordinate the relationship between the two. Therefore, on-site control should start with simple variables. The order is to find out the density first, then adjust the dot gain rate, and finally adjust the gray balance.

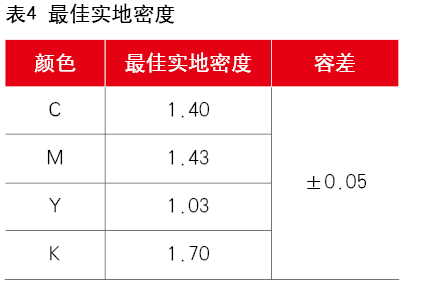

We will still illustrate with an example of on-site control. Printing conditions: Heidelberg CX920, 175 line no rinse printing plate, Sun 157g/m2 copperplate paper, Toyo TJS ink, as shown in Table 4 for optimal solid density.

01Find the density of flat ground

On the quality stability measurement and control strip, there are 5 color blocks C, M, Y, and K located in different areas of the roller axis. To level the actual density, simply adjust the ink opening within the range of ± 0.05 of the optimal density. It should be noted that about 150 sheets of paper need to be fed from the ink hopper to the stable presentation of the print. In order to establish a relatively stable ink balance, it is recommended to adjust the ink volume and start the machine to feed no less than 250 sheets of paper.

02

Adjust the increase rate of various color outlets

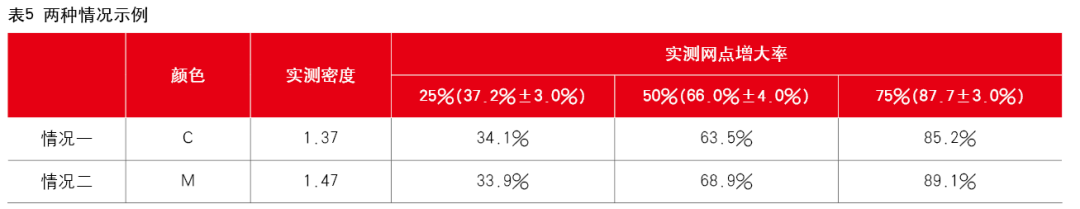

After the density of each color reaches the optimal density range of ± 0.05, check the dot enlargement rates of 25%, 50%, and 75% for each color. Due to the difficulty in accurately controlling the rate of branch expansion, there may be a problem of branch expansion exceeding the tolerance range. In this case, it is necessary to identify the problem and set an adjustment method. Two scenarios as shown in Table 5:

The C ink in situation 1 has a 25% dot increase rate lower than the lower deviation, and its actual density is relatively small compared to the optimal density. There is also significant room for adjustment in the relative upper deviation of the 50% and 75% dot values. As the ink supply increases, the dot enlargement rate also increases. Therefore, in this case, we can increase the ink supply of C appropriately before printing. This way, the 25% dot enlargement rate may meet the standard, and the actual color value of C, as well as the 50% and 75% dot enlargement rates, will not exceed the standard.

The M ink in situation 2, although also has a 25% dot increase rate lower than the lower deviation, and there is still room for adjustment between its 50% and 75% dot increase rates and the upper deviation, its actual density is close to the upper limit of the optimal density. If the ink supply of M is increased, although 25% of the dots may meet the standard, the actual density will exceed the limit. When such a contradiction arises, it is necessary to adjust the publishing and printing compensation curve of version M, increasing the 25% publishing value by 4% to 5%.

03

Adjust gray balance data

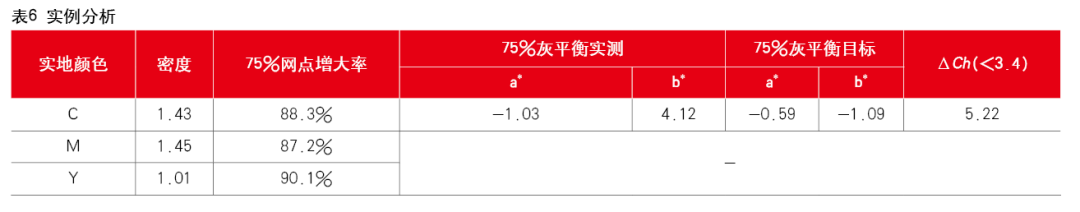

When the actual density and step adjustment increase values on the quality stability measurement and control strip meet the standards, then check whether the gray balance meets the standards. Gray balance is the result of the combined effect of solid color density and dot enlargement rate. When both solid density and dot enlargement rate meet the standard but a certain gray balance color difference exceeds the standard, the problem can only be solved by adjusting the ink supply or dot enlargement rate in the corresponding area. We will still use a set of data as an example to analyze and develop solutions, as shown in Table 6.

The data in Table 6 shows that the on-site density and 75% dot expansion rate are within the tolerance range, but 75% of the gray balance chromaticity difference exceeds the requirements.

∆ a *=a * Actual measurement - a * Target=-0.44

75% gray to green, possibly due to a larger emphasis on green or yellow, or a smaller emphasis on magenta.

∆ b *=a * actual measurement - a * target=5.21

75% gray to yellow, indicating that the yellow color is too large or the green color is too small.

Based on the above analysis, let's take a look at the density of the field and the rate of dot increase. The density of magenta field is 1.45, which has room for adjustment compared to the upper limit of 1.48. The dot increase of magenta by 87.2% also has room for adjustment compared to the upper limit of 90.7%. Therefore, the amount of M ink in this area can be appropriately increased; There is room for adjustment between the yellow solid density of 1.01 and the lower limit of 0.98. The increase rate of yellow grid points is close to the upper limit, and there is a large adjustment space downwards. Therefore, the ink volume of Y can be appropriately reduced. After adding M and subtracting Y for trial printing, the data is shown in Table 7.

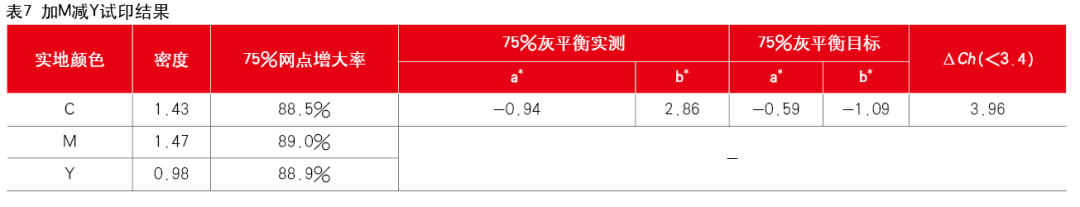

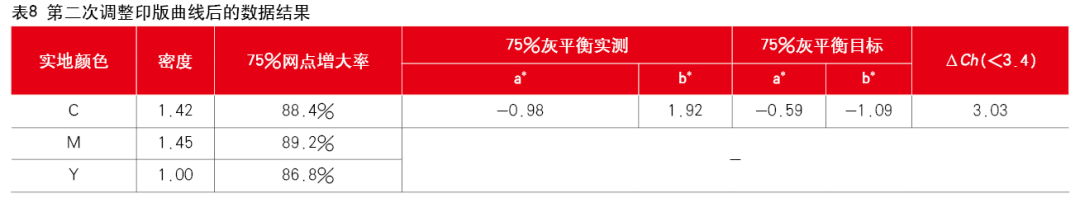

After the first adjustment of printing, the condition of 75% gray balance yellowing was improved, but it still did not meet the standard. At this point, another problem was encountered. Yellow was close to the lower limit of the optimal density, and magenta was close to the upper limit of the optimal density. At this point, it was no longer possible to improve the gray balance by reducing Y and adding M. The ink volume could not be adjusted, and the problem of 75% gray balance yellowing could only be further reduced by reducing the dot enlargement rate at Y75% through the published printing compensation curve. Therefore, the yellow publishing curve was adjusted to reduce the number of outlets by 2% at 75% for republishing and printing, as shown in Table 8.

After the second adjustment of the printing plate curve, the printing was published, which further improved the problem of 75% gray balance yellowing and achieved the required results.

This example uses 75% gray balance control to illustrate the control method. In fact, when changing the ink volume, it will also affect the dot enlargement rate and gray balance data at 25% and 50%. Therefore, it is still necessary to comprehensively consider the impact of these two changes. Fortunately, the ash balance at 25% and 75% is relatively stable and easy to pass. In addition, when the increase rate of the tri color dot is relatively close (mid-range expansion<2%), the gray balance is often easier to improve through ink volume adjustment.

The above is our practical experience in C9 quality stability evaluation, hoping to be helpful to peers.