Is it easy for light background prints to have uneven ink color? Why not give this process a try!

With the updating and replacement of various printing methods, traditional cigarette label printing processes are constantly innovating. The commonly used cigarette packaging printing methods include offset printing, relief printing, gravure printing, orifice plate (screen printing), etc. Each printing process has its own characteristics in presenting product effects. Traditional offset printing has good reproduction performance in many aspects such as light ink color, printing dot hierarchy, and detailed information of printed products. However, it is difficult to control the thickness of the ink layer for large format base color products, especially for light format large format printed products. Quality problems such as color instability and uneven ink layer are prone to occur during the printing process, leading to an increase in product scrap rate, causing losses to enterprises, resource waste, and unsustainability. Although the color difference is unstable and can be adjusted through real-time monitoring by machine operators, which requires high standards from operators, it is still difficult to ensure the consistency of product color batches.

Traditional flexographic printing uses a mesh roller to transfer ink, which can effectively control the thickness of the background ink layer on a large surface. It has relatively low requirements for operators and is more convenient to control the thickness of the ink layer, especially for light background printing products on a large surface. It can effectively control the uniformity of the product's ink color through stable transfer of ink layer thickness.

The author's company currently has a Roland 8+2 offset printing press, which is a production equipment that combines the characteristics of thick ink layer and uniform and stable ink color in flexographic printing with the clear layering of offset printing dots and good reproducibility of detail information. Flexographic printing is responsible for the color stability of light background colors on large pages, while offset printing is responsible for the reproducibility of product graphic and textual details, thereby achieving the characteristics of stable color difference, clear hierarchy, and rich details in printed products, truly achieving the effect of complying with the original manuscript and being faithful to the standard.

Taking a product from a certain tobacco company as an example, the main color of the product is a full page light yellow background. During the production process, the color difference stability is not high due to the level of operators, the technical experience of ink blending personnel, the operation status of equipment, and the stability of materials. Based on the characteristics of the product, the R&D team conducted process testing and recorded analysis from the aspects of mesh roller, ink thickness and viscosity, printing paper, printing process analysis and improvement, and repeatedly verified the stability and adaptability requirements of the above indicators for product quality on the machine, achieving phased results. The author will explore the process of achieving stable color difference and uniform ink color in large format light base products through the improvement of adhesive flexible bonding technology from the following aspects.

Process selection of paper, ink, and plate rollers

01 Performance analysis of printing materials

The single-sided coated white cardboard used in this product is made by applying white coating on one side of the base paper and then processing it through calendering decoration. If the paper is unevenly coated or has uncoated paper, the uncoated paper will have problems such as surface fiber interlacing, rough and uneven substrate surface, and fiber gaps larger than the diameter of the printing dots, resulting in the dots being exactly in the gaps between the fibers and unable to transfer ink to the surface of the paper, making it impossible to reproduce the image in this area.

During the printing process, the product may experience uneven ink color, loss of dots, and poor leveling of the printing surface due to the uneven surface of the paper. The flatness of the printing paper surface and the ink absorption of the coating are important factors affecting the printing performance of the product. Therefore, in terms of the selection of base paper and surface coating requirements, in addition to in-depth technical exchanges with paper mills, we have also made process improvements under our own printing equipment conditions, maximizing the flatness of the paper surface and improving printing adaptability.

01

Firstly, choose a base paper with good flatness, such as Senbo Bowang SBS (white core white card) or Hongta Renheng SBS (white core white card). Their surface flatness stability is high and can be tested and compared in different schemes to choose the better one.

02

Secondly, improve the coating effect from various aspects such as paper coating equipment debugging, calendering, and coating scraper.

03

Thirdly, by adjusting the coating formula, the ink absorption performance of the coated paper can be improved, ensuring that the paper coating is firm, without bubbles, streaks, and the surface of the paper is smooth and free of impurities; Ensure that the surface smoothness of the paper is above 400S, so that the white cardboard can tightly contact the printing plate and clearly restore the printing dots.

04

Fourthly, in order to avoid printing quality problems such as inaccurate dot printing, uneven ink color, and loss of dots during the printing process of the product, the first seat of the equipment needs to be filled with UV fading agent on the surface of the paper to prevent UV flexographic ink from penetrating and effectively remove ink skin, level paper pits, and improve the surface smoothness of tobacco paper.

02 Printing Ink Selection and Control

Firstly, in the selection of printing ink, water-based ink is prone to clogging the mesh roller during the printing process and must be cleaned with professional cleaning agents, resulting in interrupted and unsustainable printing and affecting color stability; Environmentally friendly UV cured flexographic ink can achieve instant curing of the ink layer under UV light irradiation, without sticking or clogging the mesh roller, while effectively controlling the phenomenon of dot enlargement and ensuring stable quality and high production efficiency. It can maintain the firmness of the ink layer, the stability of ink viscosity, and the consistency of printing color, and also better protect the ecological environment.

Secondly, the thickness of ink particles and the viscosity of ink also have a significant impact on the printing effect and post press product quality. If the ink particle thickness and ink viscosity are not controlled properly during the printing process, it will cause the edges of the printed product dots to become hairy, the dots to deform, the dots to expand, and also affect the amount of ink transfer; Even leading to poor adaptability in post-processing and hot stamping of the product, resulting in problems such as gold loss, paste, and even ink explosion in the finished product. Therefore, the thickness and viscosity of ink particles should be strictly controlled during the testing process.

Characteristics and adaptability of 03 version roller

In the process of flexographic base color printing, ceramic mesh rollers have the characteristics of high printing resistance, corrosion resistance, high temperature resistance, regular mesh holes, smooth mesh walls, fast ink release, easy cleaning, and low blade wear. They not only have a long single use time, but also have a longer service life of the printing plate; The dot holes generated by laser engraving technology are deeper and smoother, which is more conducive to the uniformity of ink transfer in printing.

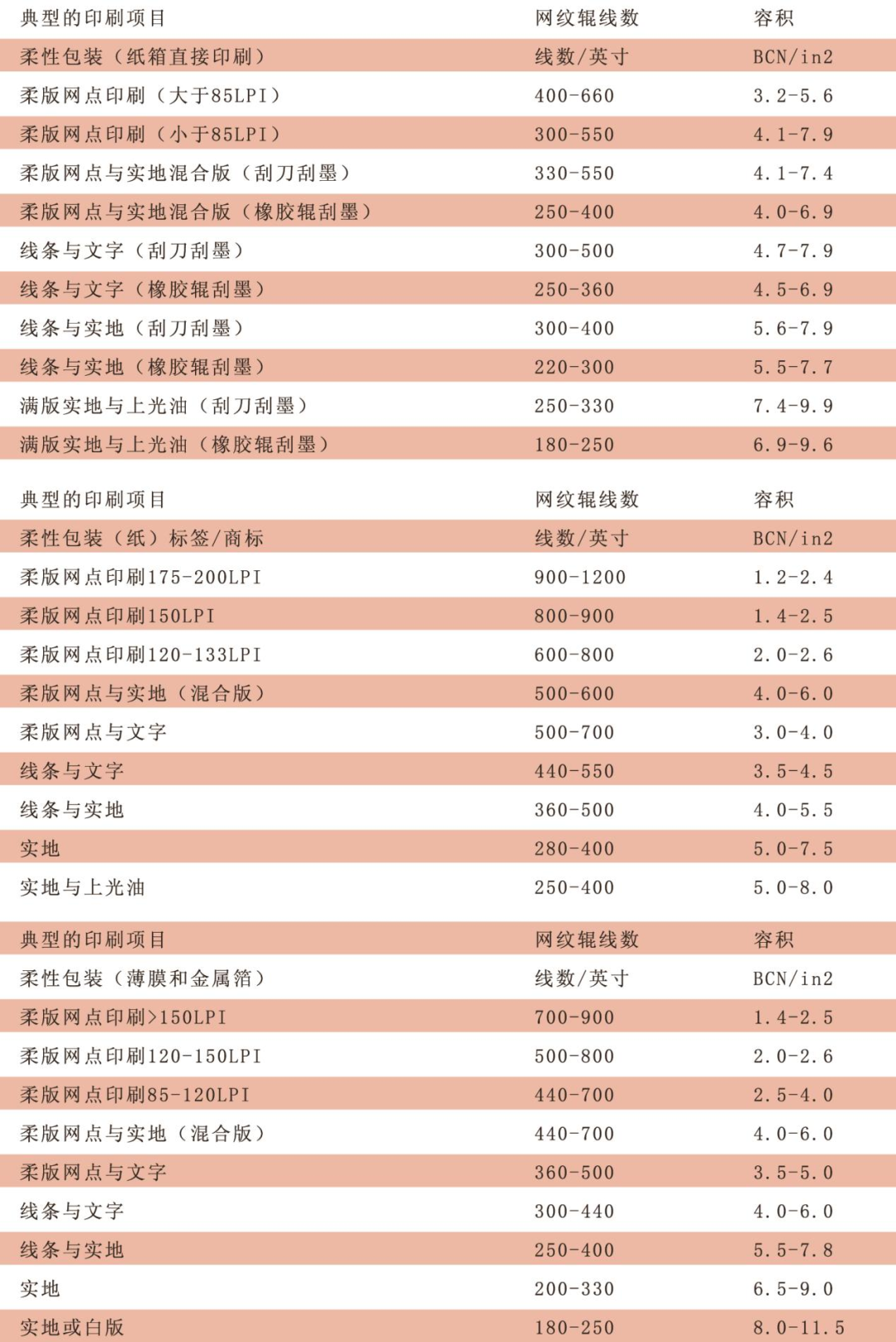

At the same time, the most important parameters of ceramic mesh rollers are the number of mesh lines and the amount of ink in the mesh holes. The higher the number of mesh lines, the thinner and more uniform the ink layer can be formed, and the more rich the expression levels and details of the dots can be. During the printing process, it can reduce dot expansion and maintain a constant and uniform ink transfer rate. If there are quality issues with the printed product such as insufficient ink transfer for light colored dot printing, limited surface flatness of the paper, inaccurate printing on the ground, loss of dots, and powder or hair loss during the printing process, we need to select and test the appropriate number of mesh lines and hole coating amount for the mesh roller based on the characteristics of the printing material, as shown in Table 1.

Table 1: Ink Load and Network Cable Specifications for Commonly Used Flexographic Projects

Product on machine printing and process validation

Through preliminary planning and preparation work, the product has met the conditions for machine testing. This test will be conducted in stages to ensure that each test achieves the expected goals. Based on the comparative analysis of data on the smoothness of single-sided coated white cardstock from different paper mills over the years in our company's testing center laboratory, it is not difficult to see that compared with imported coated white cardstock, domestically produced coated white cardstock has become increasingly sophisticated in terms of flatness technology processing. After comparing the testing data of materials from different domestic suppliers and comparing their actual testing results in different printing products, Senbo Bowang SBS (white core white cardstock) and Hongta Renheng SBS (white core white cardstock) were selected as the test papers for this experiment. Considering the impact of environmental temperature and humidity on testing results, printing environment temperatures that are too high or too low will cause changes in ink viscosity and affect product ink transferability. Therefore, the test environment temperature will be controlled at 23 ℃± 5 ℃ and humidity will be controlled at 45% to 60%, which is basically suitable for normal production temperatures.

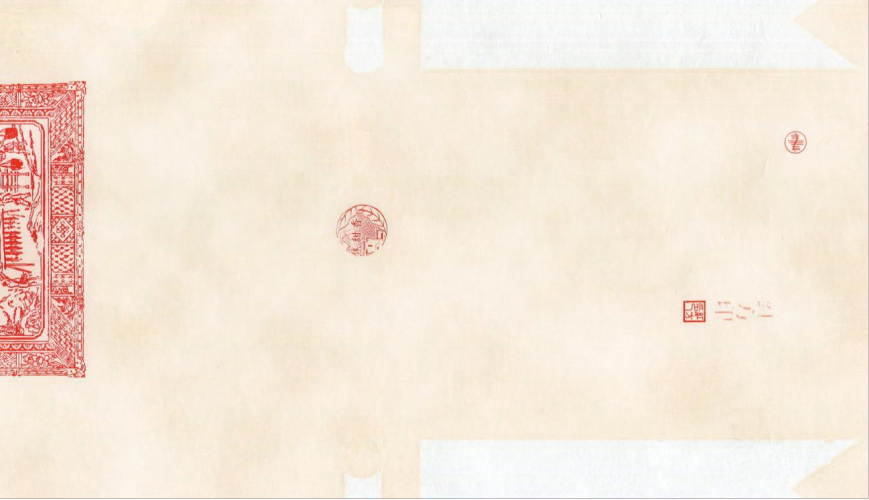

In the first stage, a honeycomb ceramic mesh roller with a mesh ink content of 13g/m2 was tested on the machine, using a 60 ° arrangement of regular hexagonal dots. Its characteristics are good ink transfer, small embossing, and few marks. However, during the testing process, there were pockmarks on the surface of the paper, thick ink layer accumulation, back pulling, and even meteor shower phenomenon on the surface of the printed product. As shown in Figure 2.

Figure 2: Full plate meteor shower appears on the surface of the printed material

On site analysis shows that there are several reasons for the occurrence of the meteor shower phenomenon. Firstly, the honeycomb shape of the mesh roller leads to poor ink imprinting and uneven ink layer; Secondly, the uneven control of the depth of the carved mesh holes leads to uneven accumulation of ink layers. Therefore, by changing the parameters such as the shape of the mesh holes, ink volume, and the number of dot lines of the ceramic mesh roller and testing it again on the machine, the process parameters of the ceramic mesh roller were finally determined to be a diagonal mesh roller with a mesh ink volume of 9g, a spiral triangle dot shape, and a dot line number of 100I/cm (250I/in). After testing on the machine, the ink layer was thick and smooth, without any pulling or ink dropping phenomenon.

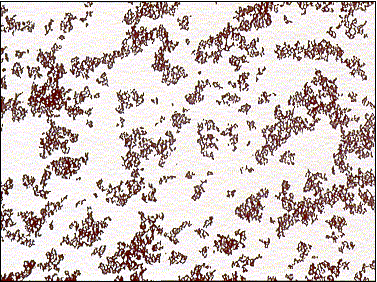

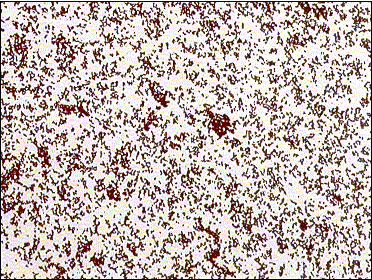

In the second stage, light base inks with different ink fineness were tested, and some schemes showed poor ink adhesion on the surface of the substrate, dark and deep clustered spots on the surface of the printed product, and poor glossiness of the printed product. Due to the thin ink layer in offset printing, there is a high requirement for the particle size of pigments in the ink composition. The large particle size of pigments is the main reason for the roughness, spots, and poor glossiness of printed products. Therefore, by selecting the ink fineness from suppliers or adjusting the ink development process to adjust the ink fineness, the adhesion of ink on the substrate surface and the glossiness of the printing surface were greatly improved after retesting on the machine, as shown in Figure 3 and Figure 4.

Figure 3: Poor grinding of pigments leads to poor dispersion of pigments

Figure 4: The pigment is well ground, resulting in uniform dispersion of the pigment

In the third stage, the problem of ink back pulling is mainly caused by poor dryness of the ink on the surface of the printed material during the testing process. The processing method is to leave the remaining units of the 8+2 offset printing machine, and empty the two units behind the flexographic printing unit. On the one hand, this can prolong the drying time of the ink on the surface of the printing material, and on the other hand, it can assist in improving the adhesion of the ink on the surface of the printed product by controlling the pressure between the spare rollers. After machine testing, the drying of the ink layer and the phenomenon of back pulling were significantly improved.

Of course, during the testing process, we should not ignore the impact of ink viscosity on the printing effect. After multiple rounds of debugging and verification by ink adjusting technicians and machine operators, it was confirmed that the viscosity of the UV flexographic printing base yellow is 21 seconds, and the viscosity of the matching water-based online varnish is 27 seconds, which can ensure uniform ink color, flat large surface, and good wear resistance protection of the ink layer in printed products.

At the same time, we can also compare the stability of the color difference of the product's light base color and the compatibility between light base color and other spot color inks for overlay printing. The conclusion is that the surface color of the printed product with flexographic water-based yellow ink is dark and the glossiness is not high, while the ink layer thickness of flexographic UV spot color ink is flat and the color is bright, as shown in Figure 5 and Figure 6.

Figure 5 Flexographic water-based base yellow ink

Figure 6 Flexographic UV sole yellow ink

After achieving the above objectives, we should also consider how to improve its stability and post-processing adaptability. Stability refers to whether its firmness is affected by external factors such as light, heat, mechanical friction, pressure, humidity, etc; Post processing adaptability refers to whether there are new risks and hidden dangers when the product enters subsequent processing stages such as screen printing, hot stamping, embossing, die-cutting, etc. Therefore, surface modification testing needs to be conducted simultaneously. Tests have shown that applying clear varnish on the surface of printed materials can improve surface flatness, increase product surface protection, enhance ink layer wear resistance, and improve post processing hot stamping effect. As shown in Figure 7.

Figure 7: Heat resistance effect of printed materials

We also know that it is difficult to achieve uniform and stable surface coating on paper, which poses a risk to the stability of the final printed product. In the case of stable color difference of the base color, verification and determination of the parameters of the mesh roller, and basic determination of process improvement testing, due to uneven surface coating on some paper, there may be base color pulling and fuzzing phenomena. We have returned to the early stage of paper selection. If paper inevitably has such hidden dangers, we can consider pre coating the surface of the paper with a full layer of UV fading agent in the first unit of the equipment, and comparing it with the scheme without UV fading agent. The effect is self-evident, and the hidden dangers are also eliminated, as shown in Figure 8 and Figure 9.

Figure 8: Primer without UV fading agent

Figure 9 UV fading agent base

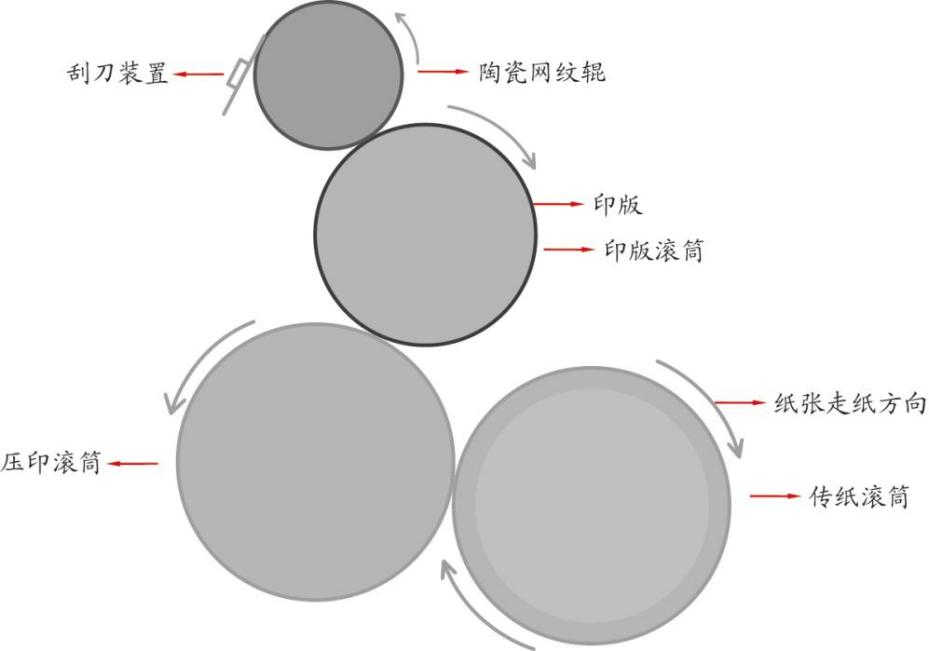

In the fourth stage of small-scale trial production, it is necessary to pay attention to the reasonable arrangement of printing color sequence, strictly control the process parameters during production, and adjust the parallelism between the ceramic mesh roller, plate cylinder, and impression cylinder, as well as the pressure at both ends between the three cylinders. The printing paper is filled with UV fading agent from the first unit and then transferred to the second flexographic printing unit. The machine operator adjusts the pressure between the ceramic mesh roller, plate cylinder, aluminum base resin plate, and impression cylinder by observing the ink transfer on the printing graphic surface to ensure the clarity of the printed product surface, as shown in Figure 10 and Figure 11. The printing plate adopts an aluminum based resin plate, which has the advantages of good overlay accuracy, pressure and printing resistance, flat ink layer, and small deformation.

Figure 10 Schematic diagram of the flexible printing unit of Roland 8+2 offset printing machine

Figure 11: Ceramic Mesh Roller (left) and Aluminum Resin Plate (right) of Flexographic Printing Unit

During the production process, in order to ensure its drying effect, the UV drying parameters of each unit are roughly as follows. The first unit has a UV lamp with a power of 7kW for removing the dilution agent, which is fully turned on; The light base color UV lamp of the second flexographic printing unit has a power of 12KW and is fully turned on; The UV lamp of the eighth red unit has a starting power of 6KW and is fully turned on; The three UV lights at the rear of the car are fully turned on with a power of 3 × 15KW; the three infrared lights are fully turned on with a power of 90%, and the hot air is fully turned on at 100%. The test site is shown in Figure 12.

Figure 12 Online Test

At this point, the entire testing and small-scale trial production have been completed. For the light base color cigarette pack products, we have modified the existing equipment, adjusted the process parameters such as the shape of the ceramic mesh roller dot, the number of mesh lines, and the ink volume of the mesh holes. After selecting the flatness of the paper surface, adjusting the ink particle thickness, using UV fading agent as a base to improve the unevenness of the paper surface, and applying environmentally friendly UV curing ink, we have continuously adjusted the parameters of the adhesive flexible printing equipment, and finally achieved mass production of light base color products.

Of course, the application of adhesive soft combination is also applicable to other similar light base color products. It has great reference significance. The author hopes to inspire more and more new materials, processes, technologies, etc. to constantly emerge and contribute to quality improvement, green environmental protection, energy conservation and consumption reduction.