Four easy steps to create a master with two holographic laser patterns!

Anti counterfeiting laser packaging materials, due to their anti-counterfeiting function, as well as their brilliant colors and patterns, or dynamic, 3D and other effects, give people a strong visual shock and are widely used in packaging such as cigarette packs, wine packs, toothpaste boxes, cosmetics, drug packaging, as well as printed materials such as advertisements, picture books, and decorations. This type of packaging has an immediate effect on eliminating counterfeit and inferior products, as well as promoting and advertising the products. The research and development focus of new anti-counterfeiting laser packaging materials is on holographic laser film products, and the key to research and development is to develop and produce holographic laser plates with various patterns, novelty, and high quality.

Due to the high cost of advanced holographic laser plate making equipment and the lack of advanced holographic laser plate making technology, high-quality holographic laser plate making is very difficult. Currently, there are few excellent plate types on the market, and the patterns of holographic laser plate large plates (800mm × 600mm specifications or above) are relatively simple, so the development of new products is limited. In response to the deficiencies in existing technology, we have developed a laser master production method that simultaneously has two holographic laser plate patterns, and proposed a solution, which is to use the existing plate types to create a personalized production method by superimposing the patterns of the two holographic laser plates on one plate and developing a new version.

The main principle of this technical solution

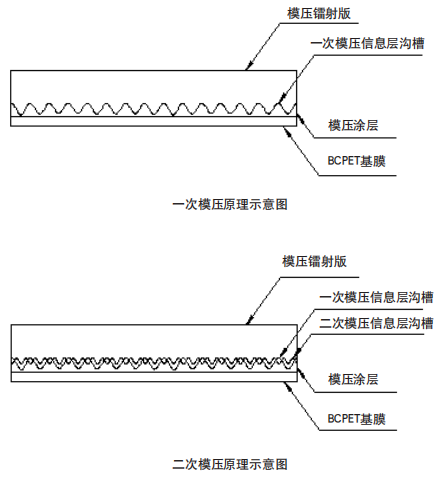

Select the appropriate coating film, first use a hard press single plate molding machine to select the holographic laser plate with relatively deep interference pattern grooves for one molding. Then, using a double pressure seamless mold press, select the holographic laser plate with relatively shallow interference pattern groove depth for secondary molding. Due to the fact that the depth of the interference pattern grooves in the holographic laser plate produced by the second molding is not as deep as that produced by the first molding, it is not possible to completely cover the interference pattern grooves produced by the first molding. Therefore, both laser patterns will be present on the film produced by the second molding.

The molded film is directly composite, with the molded information layer facing outward, and then silver plated and electroplated with gold nickel plate to produce a laser master with two holographic laser plate patterns as required.

Specific implementation plan

Choose a double coated pre coating film with good coating leveling and less likely to peel off, without surface discoloration issues, and the coating needs to have good compaction and high brightness during molding. The cold zone of the molded double press is not obvious.

Firstly, use a hard press single plate molding machine to select a holographic laser plate with relatively deep interference pattern grooves for a molding process, ensuring compaction and penetration without problems such as fracking, whitening, or flower formation. The hard press plate roller circumference should be selected as large as possible. Then, using a double pressure seamless mold press with good cold zone effect, a holographic laser plate with relatively shallow groove depth for interference fringes is selected for secondary molding. Due to the fact that the depth of the interference pattern grooves in the holographic laser plate produced by the second molding is not as deep as that produced by the first molding, it is not possible to completely cover the interference pattern grooves produced by the first molding. Therefore, two holographic laser plate patterns will coexist on the film produced by the second molding, as shown in Figure 1.

Figure 1 Schematic diagram of the pattern process of two holographic laser plates simultaneously present

The relative brightness between the first and second molding can be adjusted by adjusting the temperature of the plate roller for the second molding. The film that has undergone secondary molding is not aluminum plated and is directly sent to the composite workshop for composite using glass cardboard. The molded information layer faces outward, ensuring the flatness of the composite surface and avoiding issues such as scratches and abrasions. Finally, select and cut a section of composite paper larger than one hard press plate circumference, inspect the surface for defects, and perform silver plating treatment. After silver plating, electroplating can be carried out to produce the required laser master with two types of holographic laser patterns. The specific steps are as follows.

(1) Choose a double coated pre coating film with good coating leveling and less likely to peel off, without the problem of surface discoloration on the coating. The coating needs to have good compaction and high brightness during molding, and the cold zone effect of the molded double press without plate seams is relatively good. Apply a pre coated film with good leveling to facilitate coating production and achieve better molding effect; The coating is not easy to peel off, which is beneficial for the film making process, the composite process, as well as the silver plating and laminating processes without peeling off the coating; Double coated pre coating film can avoid the problem of color bleeding on the coating surface and also has a good molding effect. Generally, it is recommended to choose a concave transfer laser coating or composite laser coating that is suitable for double pressure without plate seams, with good film formation and relatively good adhesion.

The coating should have excellent molding performance, good compaction, and high brightness; In addition, the coating should have excellent performance of molded double pressure seamless film, with good transition in the cold zone and no obvious black shadow in the cold zone. Only by choosing high-quality laser coatings can good results be achieved and better laser layouts be made.

(2) Firstly, use a hard press single plate molding machine for one-time molding, and select holographic laser plates with relatively deep interference fringes and grooves; Use a double pressure seamless mold press for secondary molding, and select holographic laser plates with relatively shallow groove depths for interference fringes; By adjusting the temperature of the plate roller for the second molding, the relative brightness between the first molding and the second molding can be adjusted.

During the first molding process, a hard press single plate molding machine is used for molding. Due to the high hardness of the molding rubber roller, it can reach Shore D level, and the pressure of the molding rubber roller is relatively high, reaching 50-60kg/cm2, which can ensure good compaction. The holographic laser interference pattern groove depth can be pressed relatively deep on the molding information coating to prevent complete damage to the first molding information layer during the second molding process. When selecting, it is necessary to choose a holographic laser plate with a relatively deeper groove depth for the interference fringes, such as a laser pattern with a groove depth of more than 2u or a small lens plate. The hard press plate roller should choose the largest plate circumference as much as possible, which is beneficial for maximizing the size of the plate spacing direction during plate making. This also determines the size of the new plate making specifications. Generally, plate rollers with a plate circumference of 620mm or more should be selected, which can be suitable for most product specifications.

机翻 · 通用领域

In the second molding process, a double pressure seamless mold press with good cold zone effect is used to mold, which can ensure no gaps or obvious dark areas, to ensure that there are no gaps or obvious shadows in a hard pressed plate circumference, and to maximize the effect and size of the new holographic laser plate in the plate circumference direction. The double pressure seamless die press belongs to the middle press machine, with a roller hardness of 95-98 degrees (Shore A), which is lower than the hardness of the hard press rubber roller. The molding pressure is about 25-30kg/cm2, which is lower than the pressure of the hard pressing rubber roller, and the compaction degree will be worse than that of the hard pressing. In addition, holographic laser plates with relatively shallow groove depths for interference fringes should be selected, such as 400dpi high point mirror beam plates or plain laser plates.

Adjust the temperature of the plate roller for the second molding to adjust the compaction degree of the second molding. The higher the temperature of the second molding roller, the better the compaction degree, and the higher the brightness of the laser pattern. At the same time, the interference pattern grooves of the holographic laser plate molded for the first time were more damaged by the second molding, and the brightness of the laser pattern molded for the first time was relatively low. On the contrary, the brightness of the laser pattern molded for the first time is relatively high. The relative brightness, angle, position, etc. of the two molded laser patterns can be personalized and adjusted through molding temperature, cutting plate, and molding operation.

Technical effects and advantages

In response to the problem of few excellent versions and relatively single holographic laser patterns on the market, existing versions can be utilized to develop new versions by using personalized production methods to superimpose the patterns of two holographic laser versions onto one plate through secondary molding.

This solution overcomes the shortcomings and drawbacks of existing technology and equipment, innovates the laser plate production technology with two types of laser plate patterns at the same time, and solves the problem of few excellent plate types and relatively single laser plate patterns on the market. One of its advantages is that it can utilize existing versions to superimpose the patterns of two versions onto one, in order to develop more new versions; Secondly, personalized production of various laser plates provides greater space for laser packaging printing design; Thirdly, this method has low difficulty in developing plate making technology, high efficiency, and low cost.

Through this plate making method, more personalized plate types can be developed according to design needs. This technology can also be utilized, combined with various typesetting methods, to carry out more laser plate making process combinations, meet various customer requirements, develop more laser packaging products, generate greater economic benefits, and inject new impetus into the colorful packaging industry.