Does the problem of creasing lines on the colored surface of wine boxes occur frequently? Why don't you try this trick!

Cutting edge technology, post press process, die-cutting, hot stamping, wine packaging

In daily production, the author found that when the colored surface of the wine box is glued, there will be the following problems at the indentation line of the colored surface: if the protrusion of the indentation line is too deep, after using the glue machine to glue, there will be a situation where the indentation is not fully glued, resulting in empty glue after the wine box is formed; If the protrusion of the indentation line is too shallow, pre folding is required for molding. Generally speaking, the indentation lines tend to protrude too deeply, resulting in insufficient glue on the surface and empty glue after the color surface is formed. However, double indentation lines are more prone to the above situation due to their close spacing. In this article, the author will improve on such issues by reducing die-cutting machine adjustment time and enhancing the stability of the indentation line while ensuring the molding effect.

Before the improvement, our company generally used 23.8mm blade lines matched with 22.9mm pointed indentation lines. Based on the thickness of the color surface, we chose to use 0.3-1.0mm indentation strips for the bottom mold, and used adhesive tape to compensate for pressure on the back of the blade bottom mold. This approach has the following issues:

(1) The indentation strip needs to be matched and bonded according to the blade indentation line, and transferred to the bottom mold through the blade indentation. If it is a double indentation line position, it is difficult to install due to the width of the indentation strip itself. The indentation strip needs to be installed twice through the blade indentation line. For molds with more indentation lines, it takes a lot of time to install the indentation strip through the blade indentation transfer method. Due to the installation method of the indentation strip being to bond the indentation strip to the position of the blade indentation line and then transfer it to the bottom mold, this type of transfer may result in the edge of the indentation strip not being fully adhered. After die-cutting, there will be steps on the edge of the color surface indentation line, which will affect the aesthetics and adhesive application of the color surface.

(2) Use indentation strips to match colored surfaces of different thicknesses, and adjust the thickness of the indentation strips used at any time. If the die-cutting master lacks experience and cannot control the thickness of the indentation strip and the pressure of the local backing paper properly, it may result in the indentation being too deep or too shallow after die-cutting. At the same time, due to the compatibility issue between the indentation strip and the colored surface itself, it takes a long time to repair the bottom with the adhesive tape.

(3) If there are scraps or debris falling into the grooves of the indentation strip, it is easy to cause product indentation breakage or result in batch waste; The indentation strip is a plastic product with a relatively short service life.

(4) When the colored surface of the wine box is formed, if the indentation line is too deep after the adhesive is applied, it will not be fully filled, resulting in empty glue on the wine box; The indentation line is too shallow. When manually forming the box body, it is necessary to fully pre fold the indentation line, which requires additional manual labor. Moreover, pre folding may not be able to completely fold at the indentation line, resulting in the paper color surface being scrapped.

(5) The color surface with a large number of patterns and indentation lines requires relatively long machine adjustment time, and some cutting dies require 4-6 hours of machine adjustment time.

Select different types of indentation lines based on paper thickness

After analysis by the author, it was found that the common materials and thicknesses for wine box colored surfaces are mainly divided into 150-250g/m2 special paper with a thickness of 0.17-0.28mm, 215-275g/m2 silver cardboard with a thickness of 0.26-0.34mm, and colored surfaces with thicker film thicknesses such as brushed film and starry film. Due to the thicker film thickness, the overall thickness of the colored surface can even reach 0.5mm or more.

Generally speaking, the thickness of the paper and the height of the indentation line need to be matched. The thicker the paper, the shorter the height of the indentation line used. Conversely, the thinner the paper, the higher the height of the indentation line used. The original pointed indentation had a height difference of 0.9mm from the blade line, which relied entirely on the indentation strip and backing paper to match the die-cutting indentation. The indentation strip is a plastic product with a short service life, and the height difference between the pointed indentation and the blade line is too large. The die-cutting method determines that the stability of the indentation is not very good.

The author chose a pointed indentation of 23.4-23.6mm to be used with a 23.8mm blade line, reducing the height difference between the pointed indentation and the blade line, and controlling it at 0.2-0.4mm. The thickness of the die-cutting color surface is generally 0.2-0.3mm, which greatly shortens the height difference between the indentation line and the blade line, and further improves the stability of the die-cutting indentation. However, the installation method and height of the indentation strip urgently need a bottom mold material that can replace the indentation strip.

Adjust the bottom mold

When using indentation strips on the bottom mold, there is a problem of difficult installation of indentation strips in the double indentation position, which is time-consuming and laborious. The height of the indentation strip is generally between 0.3-1.0mm, the width of the groove in the middle of the indentation strip is generally between 1.2-3.0mm, and the width of the indentation strip itself is generally 5.5mm. It is particularly troublesome to handle double indentation. First, press out the indentation on one side of the double indentation, reinstall the indentation strip, and then urgently install another indentation strip, and then use a die-cutting machine to press out the other indentation strip. After adjusting the height of the indentation strip, finding a stable bottom mold material has become the biggest factor limiting die-cutting. Materials that are too soft or too hard are obviously not suitable. The author chooses to use an indentation line of 23.4-23.6mm, with a height difference of 0.2-0.4mm from the cutting line of 23.8mm. After removing the thickness of the colored surface, the thickness of the material used to replace the bottom mold needs to be selected between 0.1-0.3mm. The thickness variation of the bottom mold material is relatively small, further improving the stability of die-cutting.

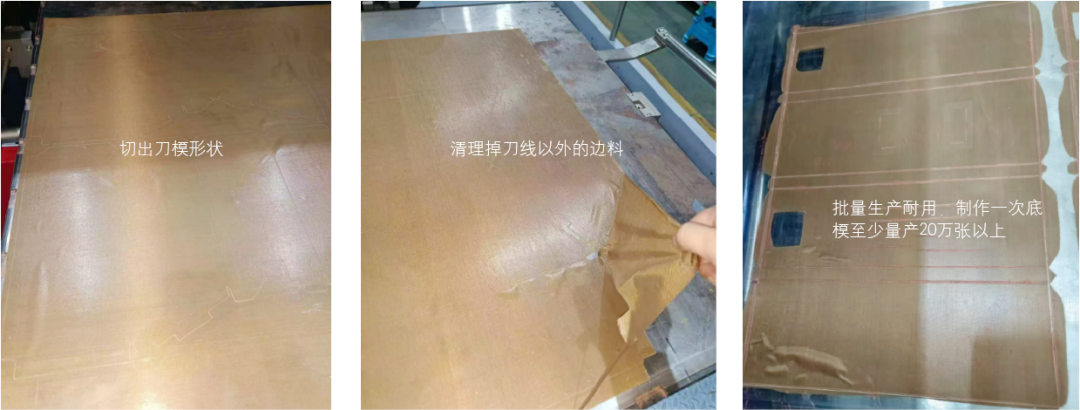

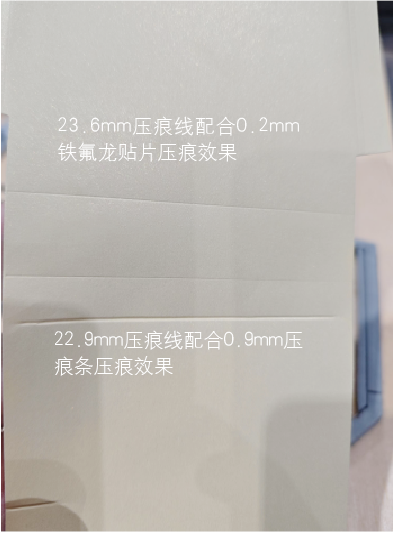

So the author chose a PTFE patch with a thickness of 0.18-0.30mm, as shown in Figure 1. First, the entire piece of the PTFE patch was bonded to the bottom mold. Then, using a cutting die, the bottom mold was cut empty, and the shapes of the cutting and indentation lines on the bottom mold were pressed out. Finally, the area outside the die-cutting was removed with a blade. Using this method for die-cutting, the indentation strip is pressed out by hard pressing. The comparison of different indentation effects on the finished product is shown in Figure 2.

Figure 1 Installation method of PTFE patch on the bottom mold

Figure 2 Comparison of finished products with different indentation effects

After improving the hard pressing mode for die-cutting, the flatness of the back indentation line is good, the overall protrusion of the indentation line is improved, and the edge steps are almost eliminated. The subsequent process is easier to apply glue, and the front folding can also be folded in place. The empty glue situation is significantly improved after the color surface is formed; At the same time, it greatly saves the installation time of the bottom mold. The originally estimated time of 4-6 hours for installing the indentation strip can be shortened to 1 hour. After the overall pressure of the bottom mold is uniform, the pressure on the upper plate can be adjusted with a supplementary bottom paper, which only requires small adjustments locally and also saves time for manual installation of the supplementary bottom paper. In addition, the PTFE patch is installed as a whole, with better pressure uniformity compared to the indentation strip, which also extends the service life of die-cutting.

This article improves the die-cutting indentation line and bottom mold by optimizing them. A 23.4-23.6mm pointed indentation line is used instead of the 22.9mm pointed indentation line, and a 0.18-0.30mm thick PTFE patch is used instead of the 0.30-1.00mm thick indentation strip. This solves the problem of glue sticking at the indentation point, reduces the time for cutting plate calibration, and improves die-cutting stability.