Digital virtual sample "black technology" - PANTORA material collection software

In recent years, many brand owners have turned their attention to digital samples to maintain efficient production, but they are struggling to replicate the material of color samples on prototypes.

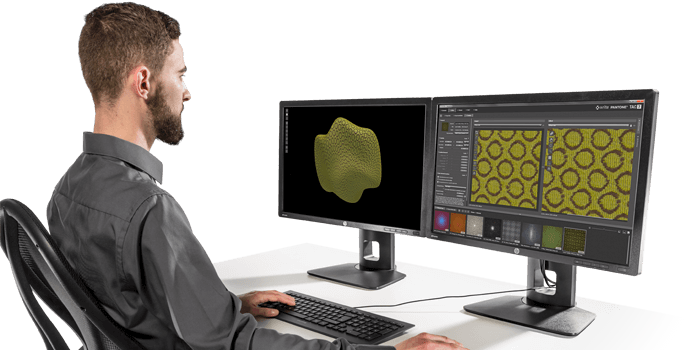

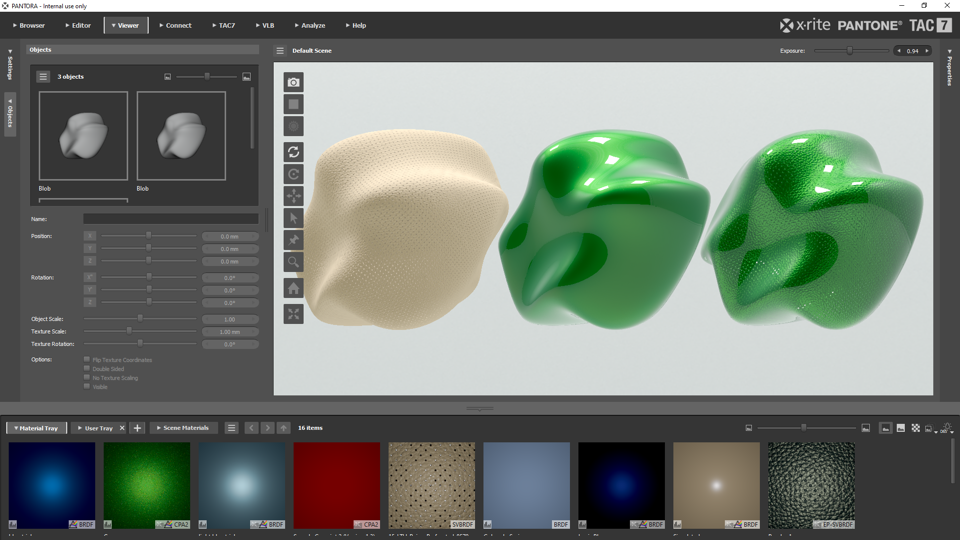

The Aiseli PANTORA material collection software can precisely fill this gap. With this desktop application, users can capture or import spectral samples and store, manage, view, edit, and render them as virtual materials. PANTORA can also digitally convert these virtual samples into a neutral appearance swapping format (AxF) for use in 3D rendering applications. Currently, our rendering partners support the RGB format. After corresponding functional enhancements, PANTORA can also convert spectral formats to RGB format.

Below we will specifically introduce how PANTORA helps brands, designers, and manufacturers in the plastic, paint and coatings, automotive, and textile industries visualize product materials and achieve faster and more sustainable design and approval workflows.

What is PANTORA?

PANTORA is a desktop application that can be installed on both Mac and Windows operating systems. It includes:

Material Viewer: It can directly search, retrieve, and import digital materials from instruments and local or cloud databases, apply materials to any geometric shape, and render them in virtual scenes to evaluate color, glossiness, texture, and lighting.

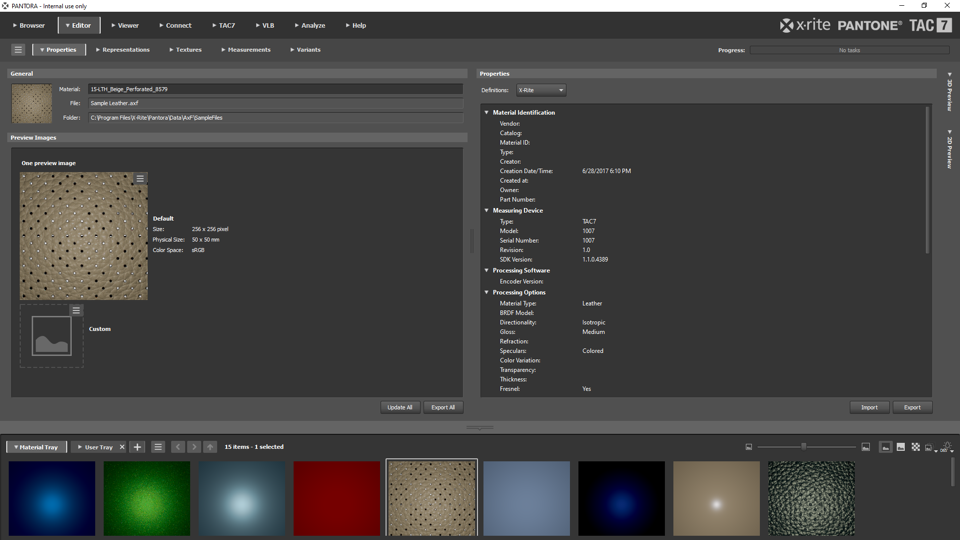

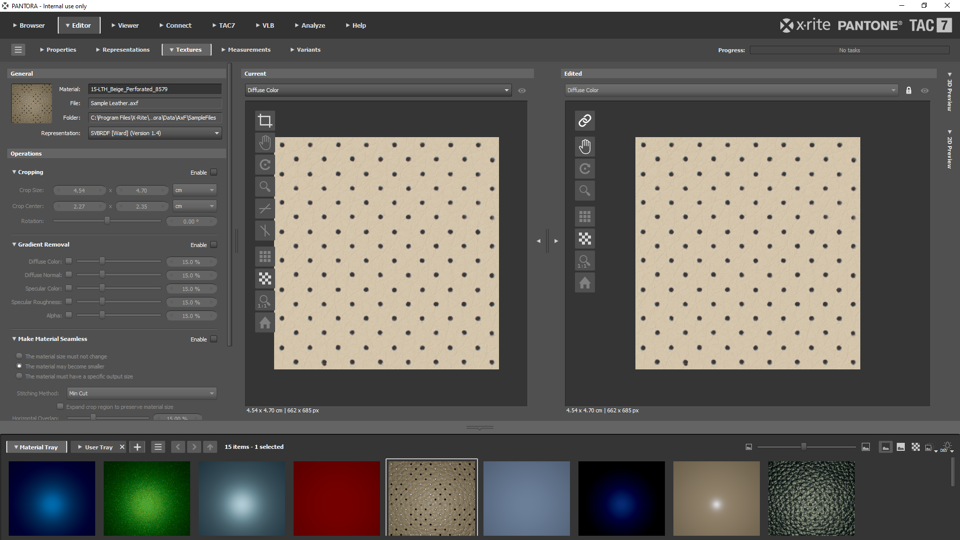

Material Editor: New materials can be created by combining measurement results of different objects. For example, textured surfaces such as leather can be recolored using measurement data from solid or effect colors. In addition, it can also manage material databases; Applications can be used to describe the properties of materials; Edit materials and textures seamlessly for subsequent rendering steps; View and export to. axf and. cxf.

PANTORA's advantages

PANTORA eliminates the need for developing physical samples and prototypes, bridging the gap between the physical color workflow and the virtual color workflow.

01 Ensure that each color is accurate

PANTORA uses spectral data as an accurate color assignment and communication method to render 3D samples.

When creating spectral data, use a spectrophotometer to measure the reflected or transmitted light of the sample within the spectral range and create the corresponding visual reflection curve. This curve describes the color on the substrate under specified lighting conditions and can even be used to distinguish extremely small color deviations.

Whether measuring fabric samples, paints, plastic pellets, or automotive coatings, spectral measurement can ensure color consistency and identify color changes under different lighting conditions.

02 Accurately display and communicate colors

Digital color is sustainable because it saves the cost of personnel travel and sample transportation required for verifying physical samples. PANTORA has also taken digital color to a whole new level!

It can visualize the appearance and interaction of colors on 3D prototypes, eliminating the need for physical prototypes. PANTORA has achieved a faster, more accurate, and more sustainable way of working.

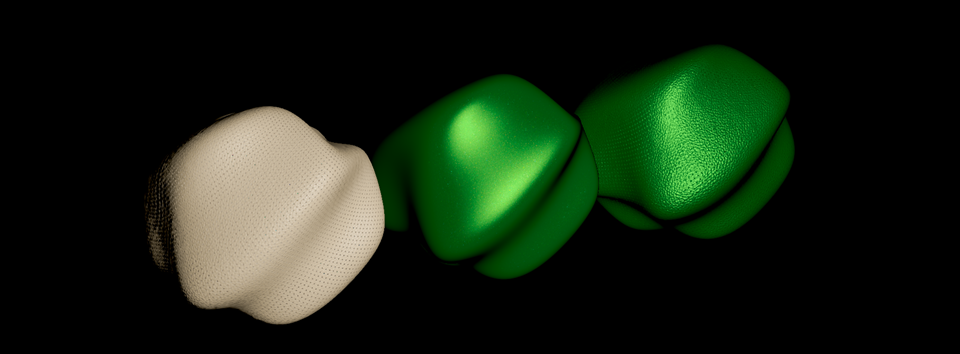

For paints, coatings, and automotive coatings, PANTORA is able to visualize flickering and angle changing effects.

For plastics, PANTORA is able to visualize the colors of semi transparent and highly reflective materials.

For textiles, PANTORA is able to visualize pixel level multispectral textures.

03 Quickly scan physical samples and create virtual materials for 3D rendering

Through PANTORA, measured material samples can be imported as. cxf files, and color measurement devices can be connected to directly measure physical samples and input the results into the software.

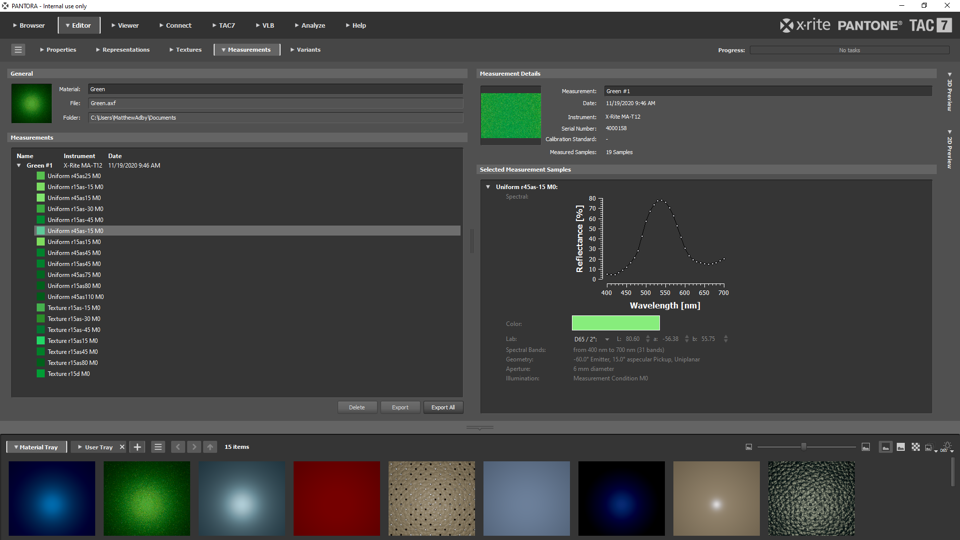

For paints, coatings, and automotive coatings, PANTORA can be used in conjunction with the MA-T12 multi angle spectrophotometer to capture extreme effect samples.

For plastics, PANTORA can be used in conjunction with the Ci7800 desktop spectrophotometer to capture the spectral transmission color of translucent materials and the reflection color of mirror materials.

For textiles, PANTORA can be used in conjunction with the MetaVue VS3200 non-contact spectrophotometer to capture multispectral texture measurements.

04 Reproduce the changes of samples under different lighting conditions

In PANTORA, different light sources can be selected to display color changes. You can even scroll through various areas of the sample to view pixel level spectral changes of plastics, coatings, and textiles.

05 Real time visualization of color

PANTORA is an economical solution suitable for any location and any sample. Its created AxF files can be exported as. cxf files and shared with others in the global supply chain, as well as used for rendering applications and quality control software.

Using PANTORA for physical samples

Perform digital exchange

In this example, we will use measurement data from green effect paint to recolor textured leather.

1. Start PANTORA and select a texture or measure a new sample

2. Use a spectrophotometer to measure color samples and input them into PANTORA

3. View measurement details and apply detailed information used to describe the measurement results

4. Transfer the surface structure of the texture to the measured color

5. Rendering initial textures, initial colors, and combination effects in 3D models

6. Change the light source and preview and evaluate changes in color, glossiness, and texture

7. Export as. cxf file, share with other stakeholders and approve new materials and colors

As the world gradually reopens, many people are hesitating whether to return to their old habits, personally visiting customer sites and sending physical samples for color decision-making and approval. This is a great opportunity to accelerate the promotion of new tools and processes to enhance our work methods and improve global sustainability.