A small improvement in the gravure printing equipment can easily solve the contact pressure problem in the production of RFID electronic tags!!

With the advent of the mobile Internet era dominated by 5G technology, the Internet of Everything and ubiquitous sensing are gradually becoming a reality. As an important means for the Internet of Things (IoT) to perceive the outside world, RFID electronic tags, especially ultra-high frequency RFID tags, will be widely applied. In this article, based on practical production experience, the author introduces the application of gravure printing in the manufacturing of RFID electronic tags and proposes some solutions to improve printing quality for readers' reference.

Technical Features of RFID Electronic Tags

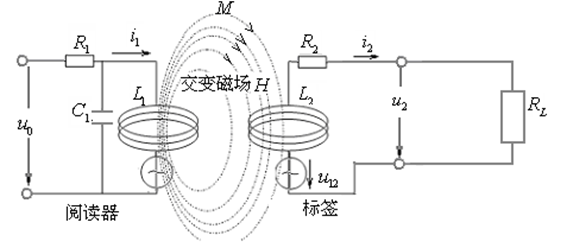

RFID electronic tags are tags that use contactless automatic identification technology to identify target objects and obtain relevant data through radio frequency signals, without the need for human intervention during the recognition process. As the wireless version of barcodes, RFID electronic tags have advantages that barcodes do not, including being waterproof, magnet-resistant, high-temperature-resistant, long in service life, capable of long-distance reading, allowing data encryption, larger data storage capacity, and flexible information updating. The encoding, storage, and reading/writing methods of RFID electronic tags differ from traditional tags (such as barcodes) or manual tags. The encoded data is stored on integrated circuits in either read-only or read/write formats. In particular, the reading and writing are achieved via wireless electronic transmission, as shown in Figure 1.

Overall, the prominent technical features of RFID electronic tags are: they can identify individual, highly specific objects, unlike barcodes that can only identify a category of items; they can read multiple objects simultaneously, whereas barcodes must be read one by one; they can store a large amount of information; and by using radio frequency, data can be read through external materials, while barcodes require lasers or infrared to read information from the surface of the materials.

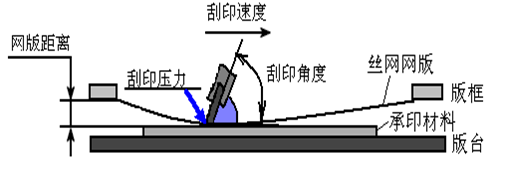

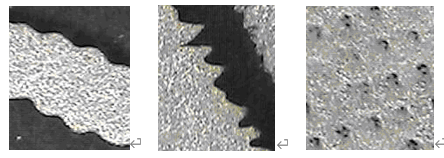

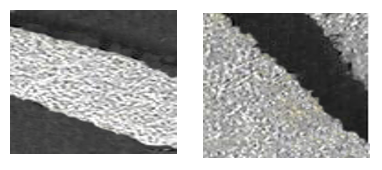

Figure 1 Schematic diagram of the working principle of an RFID electronic tagCommon manufacturing processes of RFID electronic tagsThere are three main manufacturing processes for RFID electronic tags: copper wire burning process, metal etching process, and printing process. Among them, the printing process primarily uses screen printing technology (as shown in Figure 2). Due to the limitations of the conductivity and conductive mechanism of the conductive paste, only high-silver-content conductive silver paste and low-mesh-count screen meshes can be used. Moreover, affected by multiple factors such as ink viscosity, ductility, fluidity, squeegee pressure, screen tension, and mesh interference, the printed RFID electronic tag wiring structure is prone to issues such as deformation, rough edges, short circuits, breaks, and a significant difference between actual radiation efficiency and theoretical radiation efficiency, as shown in Figure 3.

Figure 2 Schematic diagram of manufacturing RFID electronic tags by screen printing conductive silver paste

图3 丝网印刷RFID电子标签导线的局部放大图

目前,行业普遍使用铝箔蚀刻法制造超高频RFID电子标签,而普及应用超高频RFID电子标签的主要瓶颈是标签的价格,尺寸和环境适应性.铝箔蚀刻法制作天线的过程包括金属贴合,光阻印刷,金属蚀刻等,流程较为繁杂,成本偏高且不环保.其中,在印刷天线油墨方面,根据成分不同,包括银浆,铝浆,铜浆与碳浆等,以金属浆料印刷的天线效果最好.然而,目前铝,铜金属浆需高温脱氧烧结才能展现导电性,使得天线底材受到一定限制,而传统碳浆导电性未达天线应用的电阻要求,且银浆天线的制程繁琐,价格昂贵,导电性能会因弯折而降低,使得目前在市场上利用印刷方式来制作RFID天线的方式仍无法大规模生产并无法取代目前的铝蚀刻天线.而采用RFID电子标签导电浆料制作天线,其制程环保,简单且无污染,价格便宜且质量轻,适合各种无线天线的印制,在市场上无论从性能方面,还是价格方面来说,都具备十足的竞争力.

凹版印刷在RFID电子标签制作中的应用

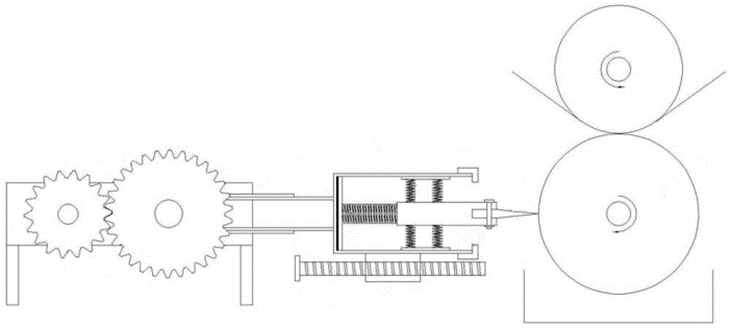

由于导电浆料具备导电性能高,兼容性强,性价比高等特点,越来越多的厂家采用石墨烯浆料印制RFID标签.由于凹版印刷精度高,速度快,生产效率高,石墨烯RFID电子标签的生产制造通常采用凹版印刷来完成.在印刷过程中,石墨烯浆料被填充到凹版滚筒的凹槽内,凹版滚筒表面多余的石墨烯浆料用刮刀刮掉,凹槽内的石墨烯浆料印刷至基材上.为适用于各种印刷场合,如不同粗糙度或不同型号的凹版滚筒,不同结构的石墨烯天线等,需要调整刮刀与凹版滚筒的接触角度,接触压力等参数,以防止所印制的石墨烯RFID电子标签天线出现结构变形,边界粗糙,短路,断路等问题.Under normal circumstances, in existing gravure printing devices, after adjusting the doctor blade angle, the working position of the doctor blade is fixed during the printing process and cannot be changed. If the working position of the doctor blade is adjusted, it may result in excessive or insufficient contact pressure with the gravure cylinder, or, due to the high precision fit between the doctor blade and the gravure cylinder, there may even be a problem where they do not make contact at all. Additionally, for gravure cylinders with low roundness precision, the doctor blade may not consistently contact the surface of the gravure cylinder, making it impossible to cleanly remove the excess graphene paste. Furthermore, if the printing device malfunctions and the gravure cylinder shakes, it can cause impacts on the doctor blade, subjecting the doctor blade and its associated mechanisms to impact stress, potentially damaging the doctor blade or its connecting mechanism, which in turn deteriorates the paste removing capability of the doctor blade. Regarding the contact pressure between the doctor blade and the gravure cylinder, existing gravure printing devices are unable to control it. Typically, it is preset based on experience, resulting in poor accuracy and adaptability to different products. This prevents setting an appropriate doctor blade pressure according to the actual condition of the product, thereby affecting the printing quality of graphene RFID electronic labels.To solve this problem, the author has improved the gravure printing device, allowing adjustments of the gravure cylinder, doctor blade, linear adjustment components, angle adjustment components, pressure adjustment components, and floating components, as shown in Figure 4.

Figure 4 Schematic diagram of components related to the gravure printing device

The specific method is as follows: the adjustment component is connected to the doctor blade and moves linearly along the radial direction of the gravure cylinder, causing the doctor blade to displace with the moving component; the angle adjustment component connects the doctor blade and the linear adjustment component, allowing the doctor blade and the linear adjustment component to rotate accordingly in order to adjust the contact angle between the doctor blade and the gravure cylinder; the rotating part is connected to the doctor blade and the linear adjustment component through a movable section, enabling the doctor blade and the linear adjustment component to move radially relative to the gravure cylinder.

This solution can adjust the contact angle between the doctor blade and the gravure cylinder, as well as adjust and measure the contact pressure between them, ensuring that excess graphene paste on the surface of the gravure cylinder is fully scraped off while the paste in the grooves is printed onto the substrate. RFID electronic tags printed using this gravure printing technology exhibit smooth edges, no serrations, and actual radiation efficiency consistent with theoretical radiation efficiency, effectively addressing the challenges encountered when producing RFID electronic tags by screen printing, as shown in Figure 5.

Figure 5 Local enlarged view of the conductor of an intaglio-printed RFID electronic tagThis intaglio printing technology can be applied to various printing scenarios. It prevents structural deformation, rough edges, and short circuits or breaks in printed graphene RFID tag antennas, ensuring the printing quality of RFID electronic tags produced by intaglio printing. This achieves high precision and efficiency, solving the technical challenges existing in RFID tag printing.