Three Major Star Products of Tongyin Shine at Labelexpo Asia 2025

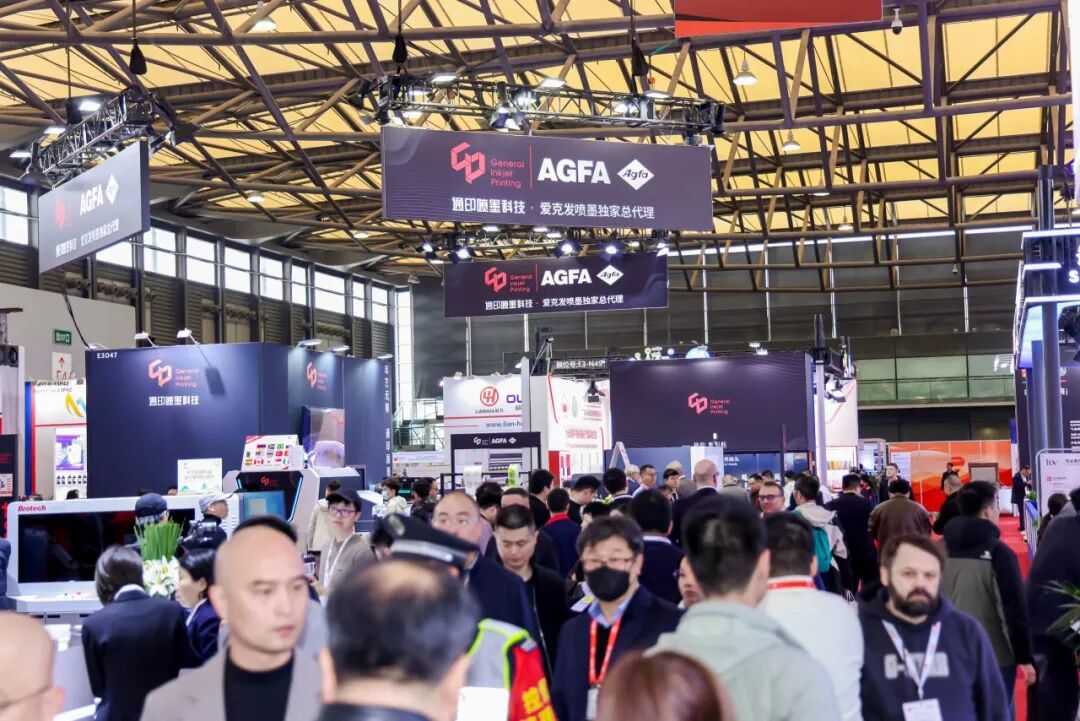

On December 2, 2025, Labelexpo Asia 2025, the largest event for the label and packaging printing industry in the Asia-Pacific region, grandly opened at Halls E1 - E4 of the Shanghai New International Expo Center. Tongyin Inkjet Technology made a strong debut at Booth O47 in Hall E3 with its Label Smart series, Label Ultra series, and the portable digital printing platform Falcon, not only offering live demonstrations of its cutting-edge equipment but also showcasing label samples across various industries, providing visitors with a visual feast of label printing technology and applications.

Three Star Products

The three core products exhibited by Tongyin precisely align with the digital and flexible development trends of the label industry and immediately became the focal point of the booth.

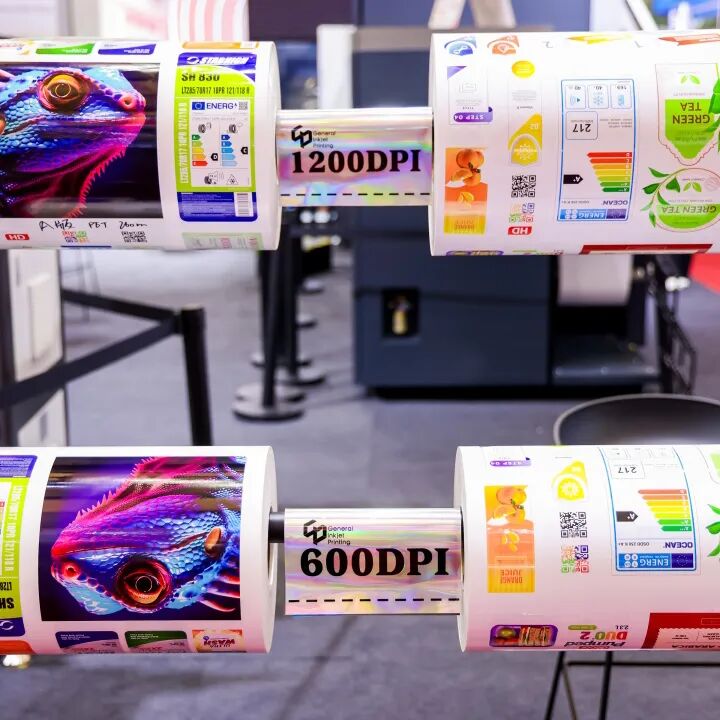

Label Smart Series

The Label Smart series, specially designed for small and medium-sized printing companies and transformation needs, has become a 'popular choice' at this exhibition. This device focuses on digital label printing scenarios and is equipped with an imported high-precision industrial printhead, offering a maximum resolution of 600×1200 dpi. Combined with eco-friendly UV ink, it produces prints with rich colors and clear details. Its high-speed printing capability of 50 m/min can efficiently handle small-batch personalized orders and seamlessly integrate into traditional production systems, addressing the limitations of conventional processes in variable data printing.

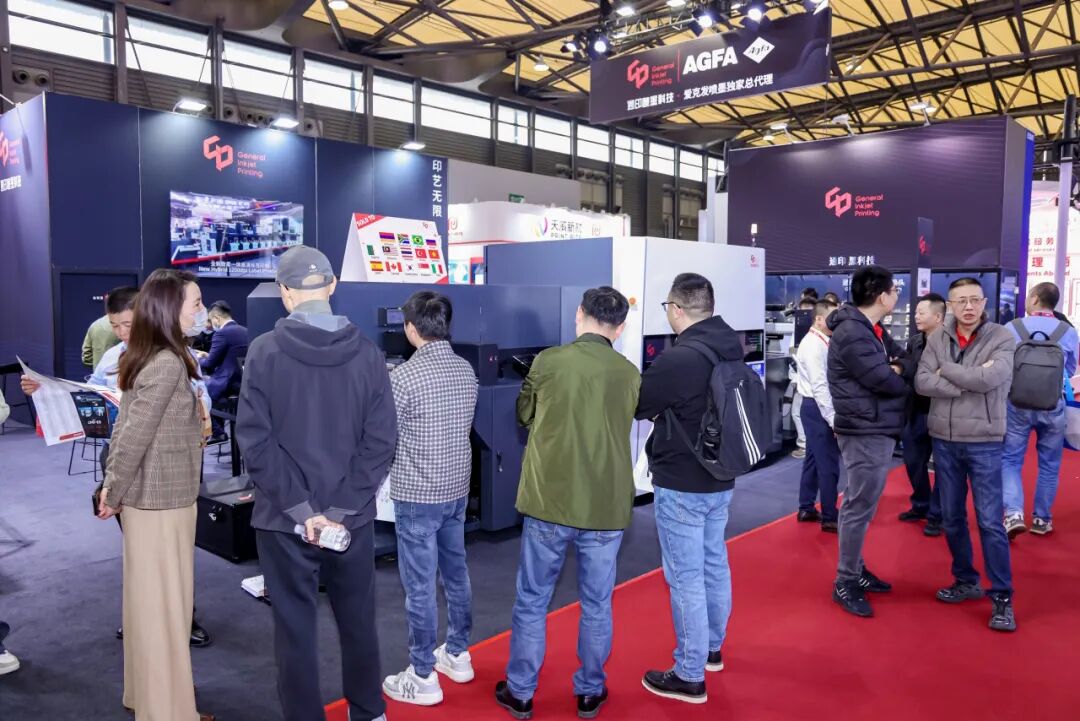

Label Ultra Series

Audiences pursuing high-quality printing stopped one after another in front of the Label Ultra series booth. As TopPrint's professional flagship product, this series delivers a high-definition resolution of 1200×1200dpi, achieving smooth and natural color transitions. Even complex gradient patterns and fine textures are perfectly reproduced. It supports up to 8 color sets, allowing, in addition to the basic four colors plus white, the addition of up to three spot color groups as needed.

What's even more noteworthy is that this series can operate at a maximum speed of 75 m/min, meeting the efficiency requirements of large-scale standardized production while also adapting to the craftsmanship demands of high-end custom orders, perfectly balancing professional quality with production flexibility.

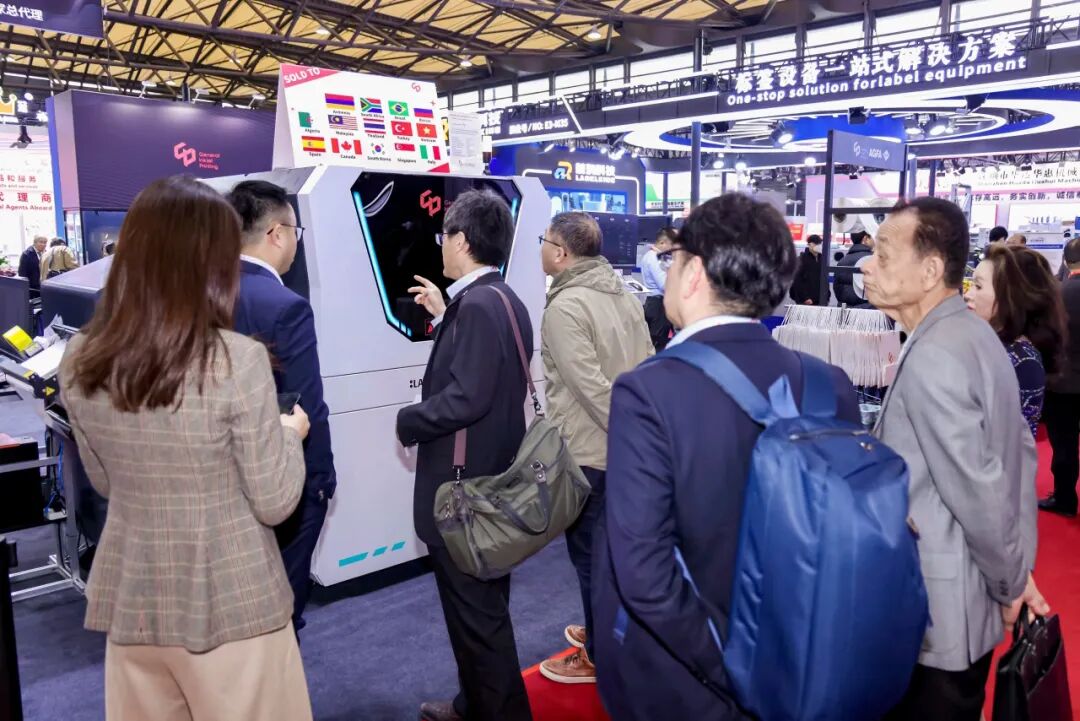

Falconseries

The Falcon, a mobile digital printing platform that breaks the limitations of fixed printing scenarios, has also become an innovative highlight of this exhibition. It allows for customizable process sequences and can be easily added to existing flexographic production lines, with a maximum operating speed of 80 meters per minute, equipped with Kyocera 1200×1200dpi high-resolution print heads.

With its flexible process combinations and stable print quality, this equipment can well meet the production needs of complex orders such as medium-to-short runs, personalized customization, and variable data, providing strong support for label printing factories to cope with diverse market demands.

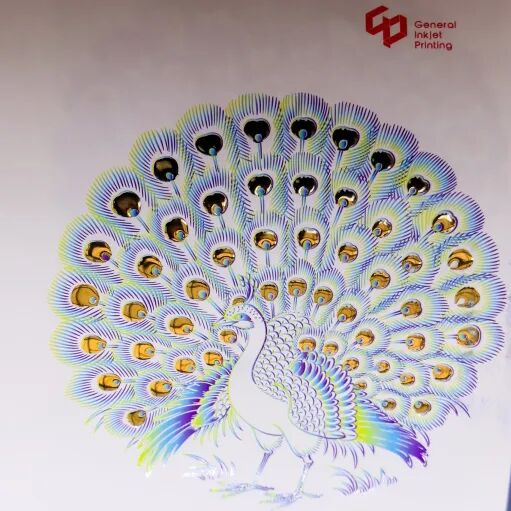

Various Label Samples

In addition to the three core pieces of equipment, the label sample display area at the Tongyin booth was also popular. From anti-counterfeiting traceable labels to personalized color labels for the cosmetics industry, as well as specialized labels for alcoholic beverages, these application cases covering the entire industry intuitively demonstrated the adaptability of Tongyin solutions in different scenarios. Staff provided on-site explanations of the techniques for adapting equipment to different materials and processes, allowing visitors to clearly understand the full process optimization from equipment to finished product.

Applications for Various Labels

Tongyin Hi-Tech

The core control technology of Tongyin's inkjet printing equipment is its independently developed printhead board technology. It adopts an innovative architecture of "one printhead per independent board" and is equipped with the latest chip, offering both low energy consumption and high data throughput. It can accurately control the printhead firing frequency, droplet size, and temperature. Together with nozzle compensation and color management functions, it achieves high-definition output and printing quality comparable to offset printing.

Topic Sharing

During the exhibition, Tongyin Product Manager Yu Lingfeng also delivered a themed presentation at the E4 Hall T8 Forum area titled "The Integration of Digital and Flexographic Printing Technology: How 1+1>2?" He provided an in-depth analysis of the core advantages of combining digital and flexographic printing in improving production efficiency and optimizing costs, offering valuable technical insights for industry peers.

Advantage of integrating digital and physical

Bridging the Gaps in Order Adaptation, Balancing Flexibility and Efficiency

Digital inkjet printing does not require plate-making, can quickly produce samples, and excels at variable data printing, which perfectly compensates for flexography's shortcomings in small-batch and personalized orders - flexography's plate-making process is cumbersome, and small-scale production often leads to high costs and long cycles. Conversely, flexography's capability for high-speed, stable long-run printing can complement digital printing, and its adaptability to various special substrates also expands the application scenarios for digital printing.

Upgrading Process Adaptation Capabilities, Expanding Application Boundaries

The integration of digital and flexographic printing overcomes the technical limitations of a single process. On one hand, by combining "flexography for fixed graphics and digital for variable information," it meets the needs of printing both variable content like production dates and traceability codes alongside fixed designs on labels for industries such as food and daily chemicals. On the other hand, this combination supports coordinated one-click operations across multiple modules such as coating, hot stamping, and die-cutting, with flexible adjustment of process sequences, allowing it to handle more complex label printing requirements.

Robot Interaction

To make the exhibition stand more technologically engaging and entertaining, Tongyin specially arranged a robot interaction segment at the booth, becoming a popular attraction for visiting audiences from around the world. This robot interaction is not only a fun experience but also subtly showcases Tongyin's technological expression - by linking robots with printing equipment, it vividly presents the core logic of "intelligent technology empowering printing production." Combined with Tongyin's digital-flexo integration, it continuously drives research and exploration, with technological upgrades providing a reinforcing effect.

Labelexpo Asia 2025 will continue until December 5. If you are looking to upgrade efficiency, achieve breakthroughs in quality, or expand applications in label printing, be sure to visit booth E3 - O47 to meet the Tongyin team face-to-face and unlock a label printing solution tailored just for you!