The Printing and Distribution Bureau of the Central Propaganda Department Conducts In-Depth Research in Bost: Focusing on Digitalization in Packaging Printing and Advanced Manufacturing!

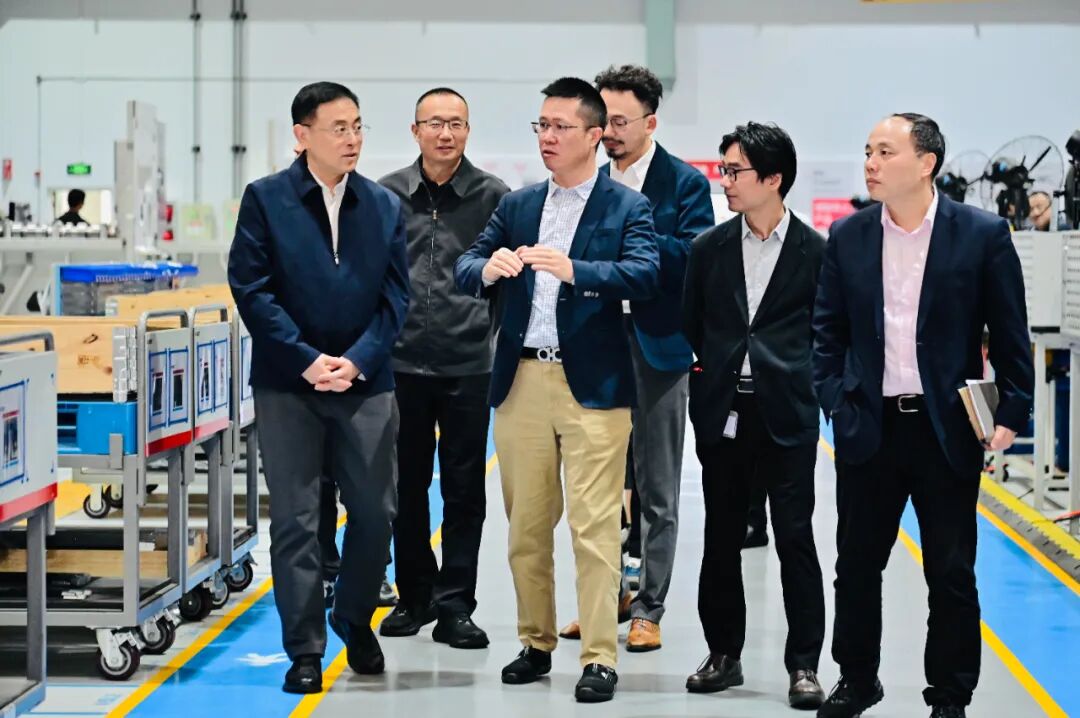

Recently, Li Yixin, Director of the Printing and Distribution Bureau of the Central Propaganda Department, Lu Zhou, Director and Second-Level Inspector of the Printing and Reproduction Division of the Printing and Distribution Bureau, Du Jianfang, Second-Level Researcher of the Distribution Division, and Zeng Yuan, Director of the Printing and Distribution Division of the Shanghai Municipal Party Committee Propaganda Department, visited BOBST (Shanghai) Co., Ltd. (referred to as "BOBST Shanghai") to conduct in-depth inspections and research on the digital transformation, advanced manufacturing processes, and sustainable development of the packaging and printing industry. Huang Jinping, Greater China Director of Corrugated Cartons and Folding Cartons at BOBST, BOBST (Shanghai) Production Director Zhai Jin, and R&D Director Wang Chengjie attended the research activities and participated in discussions.

01

In-depth Exchange: From "Islands" to "Connectivity," Reshaping Industry Productivity

During the discussion session, Huang Jinping outlined the vision of "shaping the future of the packaging world" using BOBST Group's four strategic pillars: automation, digitalization, sustainability, and connectivity, which sparked an in-depth discussion among the research team on industry development trends.

BOBST highlighted its core digital tool, the BOBST Connect cloud service platform. This platform not only enables remote equipment diagnostics and predictive maintenance through big data but, more importantly, provides foundational data support for the enterprise's MES system.

Director Li and his team expressed high interest in this, focusing on how equipment data interfaces can seamlessly integrate with enterprise ERP, MES, and other upper management systems to achieve digital transfer of work orders, and on how to leverage industrial big data to fundamentally improve equipment OEE (Overall Equipment Effectiveness) and optimize labor costs.

Regarding current market demands for customized, flexible production as well as highly efficient, large-scale standardized production, the research team explored BOBST's intelligent manufacturing model in detail. Huang Jinping explained that BOBST has transformed functional customization into standardized optional modules, constructing equipment through a "building-block" strategy. This ensures high product quality and controllable costs while maintaining a highly flexible production line, providing customers with optimal solutions that balance efficiency and versatility.

BOBST emphasized its "in China, for China" strategy. Since the planning and establishment of the BOBST Shanghai plant in 1995 and its production start in 1997, the facility has become an important part of BOBST Group's global manufacturing network. The growth of BOBST Shanghai's local R&D team and new products developed under China's leadership are leveraging China's strong manufacturing capabilities and continuous R&D iteration to supply the global market, achieving a strategic upgrade from "assembling imported materials" to "using China as the base to radiate globally." This model, integrating Chinese manufacturing advantages into the global value chain, received full recognition from the research team.

02

Visiting the Workshop: Exploring the Manufacturing Secrets Behind High Quality

After the discussion, the research team visited the BOBST Shanghai production workshop for an on-site inspection, focusing on understanding its advanced manufacturing system. Director Li and his team showed great interest in BOBST's globally unified production standards and lean production processes, and inquired in detail about the company's specific measures in assembly processes, component manufacturing, and quality control to ensure product quality stability.

The research team gained a detailed understanding of the processing and inspection procedures of key components. Zhai Jin, Production Director of BOBST Shanghai, explained that the company always adheres to unified, stringent global standards for part precision control, which forms the foundation for ensuring high-speed and high-precision operation of the equipment.

During the visit, Director Li and his delegation closely observed the equipment assembly process and recognized the engineers' meticulous assembly techniques and standardized process management. This pursuit of excellence in assembly craftsmanship reflects BOBST Shanghai's manufacturing strength and high-quality standards.

The clean and orderly workshop environment, along with standardized processes, demonstrates BOBST's comprehensive quality management system. The company is committed to ensuring that every BOBST machine reaches a world-class level through scientific management and precision manufacturing.

03

Skills Demonstration Center: Experiencing Innovative Equipment and High Efficiency

The final stop of the visit was BOBST Shanghai's Skills Demonstration Center. Here, the research team watched a live demonstration of BOBST's recently launched flagship equipment-the SP 106 AER die-cutting machine.

Through the demonstration, the team gained further insight into BOBST's innovation capabilities and manufacturing processes in post-press equipment. This machine is equipped with the latest generation of non-contact precision registration system, ACCUREGISTER, marking a comprehensive shift in the die-cutting and foil stamping process into the era of electronic control.

In addition, this model is fully equipped with automation kits to ensure high-precision, high-efficiency production, and fully digitizes the manufacturing process. By integrating with the BOBST Connect cloud platform, it can break free from traditional manual modes and achieve intelligent management of post-press operations.

This research fully reflects the high importance that the Printing and Distribution Bureau of the Central Propaganda Department attaches to high-end manufacturing and digital transformation in the printing and packaging industry. It also further affirms BOST's strategic achievements of 'In China, For China.' BOST Shanghai will continue to deeply cultivate the Chinese market, continue to drive innovation, and jointly promote the printing and packaging industry in China toward a new stage of intelligence and sustainability.