The digital printing revolution, how HP Indigo leads the industry in breaking through and restructuring

On one side is the traditional factory that continues to roar with offset printing presses, struggling to transform under the dual pressure of high costs and inventory backlog; On the other hand, digital printing has risen strongly with its innovative model of "on-demand production, zero inventory turnover, and instant delivery". The future of the printing industry is no longer a simple "multiple-choice question" of whether to turn left or right, but a "must answer question" that concerns survival - if you don't transform, you will be eliminated.

However, the transformation process of Chinese printing enterprises still lags behind.

Xu Shun'an, General Manager of Indigo/PWI Digital Printing Division for Greater China at HP

Management guru Peter Drucker profoundly pointed out that "the greatest danger in turbulent times is not the turbulence itself, but the continued use of past thinking logic." When the printing industry reaches a historic turning point, we must clearly recognize that digital printing is not simply a technological iteration, but a business model innovation that overturns tradition. From commercial printing, label manufacturing to packaging design and other diverse scenarios, its significant advantages of on-demand customization, short production cycle, and high printing accuracy accurately match the demands of the era of consumer upgrading and supply chain digital transformation.

It is not difficult to foresee that the market penetration rate of digital printing will continue to steadily increase, and it is highly likely to reshape the entire printing industry pattern in the next five years, giving rise to a new industry ecology and competitive situation.

The historical turning point of the printing industry

Transitioning to digital printing

At the beginning of this year, the research firm Smithers released a report titled "The Future of Digital Printing and Offset Printing in 2029", which showed that over the past five years, global printing scale growth has almost stagnated, with market value only slightly increasing from $887.9 billion in 2019 to $898 billion in 2024.

At the beginning of this year, the research firm Smithers released a report titled "The Future of Digital Printing and Offset Printing in 2029", which showed that over the past five years, global printing scale growth has almost stagnated, with market value only slightly increasing from $887.9 billion in 2019 to $898 billion in 2024.

But digital printing has become a bright growth point in the market. The report points out that the future value of the digital printing market will continue to climb at a compound annual growth rate of 4.8%, and the printing volume is expected to achieve a compound annual growth rate of 5.5% before 2029.

The rise of digital printing is an inevitable trend, driven by both the innovation of digital technology and the profound changes in market consumption trends.

In the past, "mass production and low cost" were the core of competition in the printing industry, and traditional offset printing dominated with economies of scale. But now, the market is accelerating its transformation towards "small batches, multiple varieties, and fast delivery". Brand owners are reducing inventory risks and packaging hoarding, while consumers' demand for personalized products is surging, making the advantages of digital printing increasingly prominent.

As Xu Shun'an said, "The core value of digital printing lies not only in 'printing better', but also in 'printing smarter'. Compared to traditional printing, which requires complex processes such as plate making, sampling, and machine adjustment, completing an order often takes more than 10 days. Digital printing only requires digital files to be produced directly, and even supports' printing from one sheet '. This ultimate flexibility has enabled industries such as food, cosmetics, and alcohol to use digital printing to meet customized needs.

From an industrial perspective, digital printing has greater potential to reconstruct the supply chain. In the past, brand manufacturers needed to plan packaging production several months in advance, but now with the help of HP's on-demand printing technology, the launch cycle of new products has been greatly compressed. At present, although digital printing will not completely replace offset printing, it is accelerating to become the mainstream choice in high value-added fields such as packaging, labeling, and publishing, "said Xu Shun'an

The next five years may become a critical period of differentiation for the printing industry, and companies that adhere to traditional paths will face severe challenges. However, pioneers who embrace digital transformation will have the say in defining the future of the industry.

Since the launch of its first device in 1993, HP Indigo has been leading the industry by setting a benchmark in digital printing with innovative technology, providing rich and leading digital printing solutions for commercial, label, and packaging printing.

Why HP Indigo

Is it a unique choice for digital printing?

In the field of digital printing, there is a saying that goes: "There are two types of digital printing, one is HP Indigo, and the other is other brands. "

To receive this praise, HP Indigo relies not only on its product technology advantages, but also on its deep exploration and continuous innovation in the digital printing market.

HP Indigo enters the high-end market with electronic ink, relying on digital imaging and liquid imaging technology to make the quality of printed products such as folding paper boxes comparable to offset printing; In the field of flexible packaging, it is the only digital printing equipment in the world that has been fully validated by the market, successfully achieving personalized production of products such as coffee bags and pet food packaging.

In fact, the competitiveness of HP Indigo is not only reflected in hardware performance, but also in the productivity leap brought by the synergy of software and hardware. Its core products, HP Indigo 120K HD and HP Indigo 18K HD, are both equipped with AI modules or tools to optimize production processes, reduce consumables consumption, and achieve efficient operations.

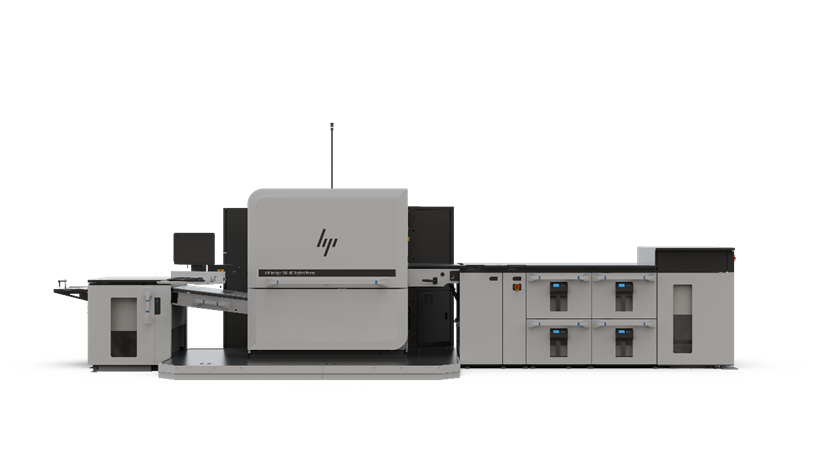

For example, the HP Indigo 120K HD, specially designed for the business printing market, not only has outstanding printing speed, but also presents high-quality products comparable to offset printing. Its built-in AI module can help customers reduce operating costs, and the new ECO printing mode can effectively reduce consumables usage by 11%, maintaining stable output even under high load production.

HP Indigo 120K HD Digital Printing Machine

As a multifunctional device, the HP Indigo 18K HD is widely used in business printing, image production, packaging printing and other scenarios. Its built-in AI driven tools greatly simplify the operation process and can efficiently meet diverse needs such as commercial applications, high-end imaging, folding paper boxes, security anti-counterfeiting, and thermal soft printing. As Xu Shun'an said, "The logo printing on the HP sponsored Real Madrid jerseys is achieved through the thermal transfer printing technology of this device

HP Indigo 18K HD Digital Printing Machine

HP Indigo 18K HD Digital Printing Machine

However, if we only measure digital printing based on product performance, it is inevitably a bit narrow. The true value of digital printing lies in the empowerment brought by the entire system.

The HP PrintOS system can be regarded as the "intelligent hub" of digital printing. It not only manages devices and optimizes production processes, but also enables data exchange and analysis, and provides professional advice to customers, decision-makers, and operators. As Xu Shun'an said, "What we provide is not just a printing press, but a complete digital production management system

In addition, the HP Indigo Mosaic variable design tool can quickly generate a massive amount of unique design patterns, making each package unique. From Xuanmai chewing gum, Coca Cola colorful bottles to Oreo cookies, HP has relied on numerous successful cases to accurately grasp customers' personalized needs, use cutting-edge technology to assist brands, and win market opportunities.

HP restructures digital printing

Business logic and growth potential

Despite the vast prospects of digital printing, the Chinese market still faces many challenges: the competition in the traditional printing market is fierce, and customers are sensitive to equipment prices. How can HP break through its high-end positioning in such an environment?

The strategy proposed by Xu Shun'an is to "keep track of the overall situation". He believes that "customers not only look at equipment prices, but also pay attention to investment returns." For example, HP equipment prices may be 50% higher than competitors, but its production efficiency can reach three times that of competitors. In the long run, the cost is actually lower.

In short, the key logic behind digital printing's subversion of traditional cognition is that 'the cost of a single product is high, but the cost of the entire chain is low'. Taking the customized packaging of Baijiu as an example, traditional printing needs more than 10 processes, such as plate making, proofing, debugging, etc., while HP Indigo equipment can be produced immediately with only electronic documents, reducing the delivery cycle to "hour level". This leap in productivity far exceeds ordinary efficiency improvements.

In addition, HP also helps customers reduce the cost of individual printing and gradually lower the threshold for customers to choose HP through consumable upgrades (such as PIP+and ink+extended lifespan), software optimization, and other measures.

The level of intelligence is the core advantage that sets HP apart from other products. Among them, Preflight learns customer preferences based on artificial intelligence and automatically predicts the appropriate printing mode; AAA 2.0 does not require manual intervention, saving 1 hour for every 80000 prints, significantly improving efficiency and reducing complaint and return rates. "

Xu Shun'an said, "PWI is HP's high-end inkjet digital printing machine. With the deepening recognition of it in the Chinese market, we believe that PWI can create greater value for customers. "

In fact, the rise of digital printing is not simply to replace traditional printing. With the deep application of digital and intelligent technologies, future digital printing will break through the limitations of the production process and run through the entire chain of commercial creative marketing, supply chain management, and business process reconstruction.

This is undoubtedly a productivity reshaping of the printing industry. In this transformation, HP Indigo has always been at the forefront of the industry, providing customers with digital solutions and continuously exploring new growth curves in digital printing.