Can you solve a two-hour problem in ten minutes? Watch how frontline pilots transform into the strongest instructors!

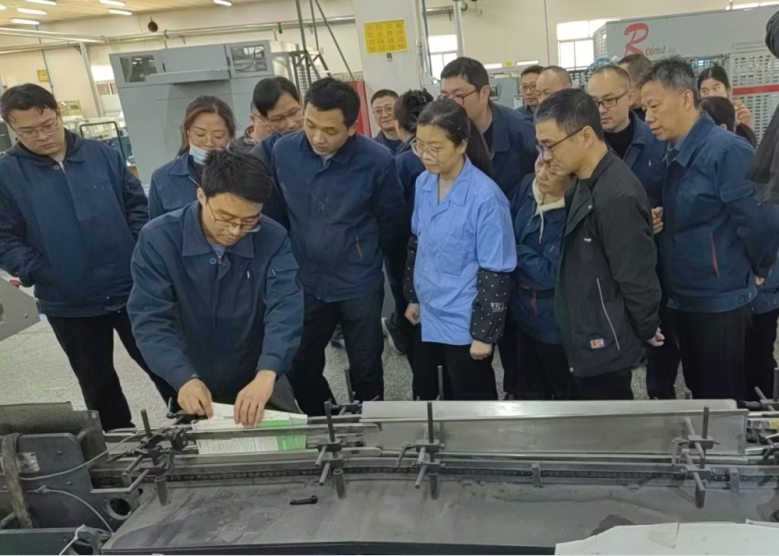

On March 19th, Jiangsu Phoenix Yangzhou Xinhua Printing Co., Ltd. Binding Center actively responded to the company's call and held a skills training session on the second glue binding line that met the needs of the captain and production pain points. During this period, adhesive technician Comrade Chen Daihai picked up two old book stickers on site and demonstrated the process of applying a thin layer of adhesive to the back of Kangxuan products while explaining. After only two trial adjustments, it was successfully completed in less than ten minutes, bringing a considerable surprise to the on-site staff. Why has the difficult problem that was difficult to solve in the past two or three hours become so simple and efficient in his hands? Why did this training attract everyone to actively participate and achieve practical results?

Targeted Diagnosis - Ask the Captain to Propose Training Needs

In order to do a good job in training, the binding center has done sufficient homework in advance and proactively assigned an important task: requiring each captain to record the problems they are not familiar with and the faults they cannot handle in their daily work one by one, in order to clarify the expected direction of training and assistance provided by the company. The common problems reported by the captain include: adjustment of the reverse pressure plate, adjustment and maintenance of the support structure, adjustment of the rubber wheel and uniform glue rod on the glue pot, frequent empty glue in the thick book of the lock line, frequent failure of automatic waste discharge, deviation of the cutting size of the three sided knife, card sticking in the channel of the slot machine, instability of the single sheet paper held by the page matching machine, and standardized operation and correct solutions for situations such as falling and shrinking pages; The lack of proficiency in sample book technology, time-consuming issues, and the coordination and complementary technical exchanges among production line personnel.

Pilots dare to face problems and admit their shortcomings, and this honesty is far more valuable than disguising, boasting, and arrogance. This fully reflects the spirit of the majority of employees who want to learn, want to work, and are willing to work. They have a sense of responsibility and urgently hope to do their work well.

The person closest to the problem is the best lecturer

After accurately mastering the captain's skill level and training needs, the next step is to conduct targeted and purposeful training. Training employees should not pursue lofty and overly theoretical goals, but should lower the threshold, seek advice from the people, and interact with the upper and lower levels. If the captain does not participate or practice, any training is meaningless.

For this reason, the binding center has carefully planned and decided to conduct training in a hierarchical and step-by-step manner. It is generally believed that the frontline captain is the one who deals with problems the most and is closest to them, and ultimately solves the problem. As the saying goes, 'wisdom lies among the masses'. Taking this opportunity to organize everyone to learn and exchange is not only beneficial for building a healthy and upward team spirit, but also a highly valuable job. Therefore, Comrade Dong Jian and Comrade Chen Daihai served as lecturers for this training, and all staff participated.

Starting from the page matching machine, Comrade Dong Jian adjusted various storage workstations, online image and text detection, and paper feeding channels according to the printing requirements. For example, regarding the setting of the thickness measurement value for book stickers, it is necessary to adjust the thickness measurement value to 190-200mm when the vise is 10cm away from the book sticker, and then rotate it three times before clamping; Image and text detection must be done through proximity switches, cameras can take photos, and waste disposal systems can accurately dispose of waste; When encountering a single page, it is necessary to reduce suction and set the thickness measurement error value to the minimum; Especially when there is disorderly posting or flipping in the channel, it must be manually removed in a timely manner to ensure that the wrong posts are cleaned up. In addition, for mechanical wear parts, it is necessary to remind leaders to assist in solving them.

Subsequently, Comrade Chen Daihai demonstrated the operation of the adhesive binding machine from the modified section. He first explained the structure of the glue binding machine, such as the book reading channel, book clip opening, book clip platform, reverse wheel, milling back, groove drawing, upper glue wheel, uniform glue rod, glue temperature, upper cover channel, cover indentation, tray opening, and height limit switch, all of which require a series of standardized operations in strict accordance with the standards. In response to the difficulty of applying thin adhesive on the back of Kang Xuan's book raised by young pilots such as Jiang Qiujun and Ren Yuling, he demonstrated the operation on site and easily solved it in just a few minutes. A series of standard movements with flowing clouds and water have attracted widespread praise, and their professional level is commendable.

According to Comrade Chen Daihai's summary, the following points should be noted when regulating such special craft products:

(2) Lower the height of the glue pot by 1mm, then return it to 0.2mm and lock it;

(3) The uniform glue rod is slightly higher than the upper glue wheel, and the temperature of the uniform glue rod is set to 18 ℃;

(4) The impact force is slightly light, just touch the back of the book, and the clamp should be slightly clamped to avoid damaging the adhesive molding of the back of the book and causing wrinkles.

To test the effectiveness of the training, the binding center convened employees again the next day and arranged for comrades Xu Aiqin, Ren Yuling, and Jiang Qiujun to conduct practical operations one by one to ensure that each trainee truly mastered the relevant knowledge and skills, achieving the goal of precise training and continuous solidification.

Through two vivid and effective trainings, employees' intrinsic motivation to actively learn and strive for progress has been greatly stimulated. Comrades Zhao Hua and Guo Wei have changed their previous style of handing over problems and waiting for engineers to solve them. They have taken the initiative to maintain and repair equipment, gradually dismantled the three sided knife, and investigated various factors that affect cutting one by one. From the three sided knife entering the book, scraping the book, tongue pressing positioning, blade installation, size adjustment, to the adjustment of the thousand pound pressure, we repeatedly studied the parts with wear, looseness, and adjustment problems, and tried our best to solve them on our own. We were busy on the machine all day without any complaints. On March 26th, under the guidance of engineers, they lightly polished another set of knife shells to ensure that they matched the knife seat. After the unremitting efforts of the two captains, the cutting quality of the three sided knife has significantly improved, and the appearance of the book is square, successfully passing the maintenance acceptance.

Organic combination of maintenance and training, promoting learning through repair

It cannot be denied that long-term operation of the machine will inevitably lead to wear and tear, as well as illness. It is necessary to seek the assistance of an engineer for necessary repairs. Repair is' treating diseases', while standardized operation and maintenance are 'preventing diseases'. Integrating maintenance with employee training is an important means of improving employee skills and preventing malfunctions.

On March 28th, two engineers from Beiren visited the company as scheduled and spent three days focusing on repairing, replacing, and adjusting the T2 cover in and out error, the three face knife clutch, the transmission shaft of the page matching machine, the T3 side glue pot breaking device, the glue pot leakage, the glue pot sprocket, the upper glue wheel, the uniform glue rod, the three face knife shell, the main motor bearing of the page matching machine, the reverse pressure plate, and the milling back mechanism. They solved the problems one by one, allowing the participating employees to learn a lot of knowledge and have a deeper understanding of standardized operation and maintenance, greatly improving the pilots' hands-on ability, analytical ability, and problem-solving ability. For example:

(1) The problem of cover entry and exit errors may be caused by wear of the cover transmission umbrella gear, improper adjustment of the front and rear positions of the book clip, wear of the main transmission gear, chain wear, and other reasons;

(2) Figure 1 shows the reverse pressure plate and milling cutter. Improper adjustment of the reverse pressure plate can cause inaccurate thickness measurement and wrinkling of the inner core. When adjusting the reverse pressure plate, attention should be paid to matching it with the outer pressure plate and back plate of the book clip to clamp the book core milling back and ensure that the milling back is flat. If the inner pressure plate exceeds the back plate of the book clip by 1mm, it will cause wrinkles on the innermost page of the book block; The internal pressure plate needs to ensure flexible rotation, otherwise it may cause wrinkling of the book core;

Figure 1 Reverse pressure plate and milling cutter

(3) The transmission shaft connecting rod of the page matching machine has gaps, loose screws, and worn universal bearings, which can cause unstable paper gripping and unstable paper dropping in the vise;

(4) There is a gap between the three sided blade shell and the blade holder, which can cause unstable cutting and skewed cutting;

(5) The binding machine is a key part of book forming, and through on-site disassembly and adjustment, it not only makes the book back form square and beautiful, but also enhances the binding strength.

Through 'learning by doing, learning by doing', employees' enthusiasm for work has become increasingly high. Despite being in the off-season of production, everyone has not relaxed at all, and their enthusiasm for learning and practicing skills is strong. We often see moving scenes of old employees patiently teaching and new employees earnestly learning next to equipment such as locksmiths, folding machines, and horse riding nails. Through the smiles of a large number of comrades such as Ren Yuling, Jiang Qiujun, Xu Aiqin, Zhu Yuquan, Li Daihong, Wu Hongxiu, Zhao Hua, Guo Wei, etc., we deeply feel that skill training is not an optional formalism, but an important task to effectively improve production efficiency, ensure product quality, reduce operating costs, adapt to technological innovation, and enhance employee confidence. It is also the golden key to realizing the personal value of employees and the development of the company!