Serving 80 publishers! After the digital transformation of this printing company, it saves over 15 million annually in production costs. What secret tricks are they using?

Feicheng Xinhua Printing Co., Ltd. was established in 1958, focusing on printing educational auxiliary books, premium books, and four-color books, with an annual production capacity of 1.5 million reams of large paper and serving over 80 publishers nationwide. The company is recognized as a Shandong Province Printing Demonstration Enterprise, Shandong Province Cultural Industry Demonstration Base, Shandong Province High-Tech Enterprise, Shandong Province Specialized and Innovative Small and Medium-Sized Enterprise, Green Printing Model Enterprise, Shandong Province Copyright Protection Demonstration Unit, and a designated printing unit for major thematic publications. Leveraging high-precision printing equipment and flexible production capabilities, the company has developed a competitive advantage in green printing and personalized customization, offering full-process services from prepress design to finished product delivery, maintaining a top-three regional revenue ranking in the printing industry for five consecutive years.

Key Approaches

01/ Issues and Needs

The company faces three main bottlenecks in its printing production:

First, fragmented supply chain data with long inventory turnover cycles for raw materials like paper and ink;

Second, traditional methods for inventory checks that consume excessive manpower and resources;

Third, quality inspection relying solely on manual visual checks, with a missed detection rate of up to 8%.

02/ Digital Initiatives

Based on these bottlenecks, the company, in collaboration with Huawei (Feicheng Base), built a supplier collaboration platform to achieve full-chain online operations and used multiple intelligent systems to construct a fully intelligent digital production line. Implementing a 'one item, one code' technology allows full-process tracking and intelligent matching in warehousing; the online monitoring system for the perfect binding machine integrates cameras and high-precision scales to ensure printing quality. By collecting data on energy consumption, equipment efficiency, and performing in-depth analysis, scheduling is optimized, comprehensively improving production efficiency and product quality.

(1) Digitalized Process Connectivity, Intelligent Production to Reduce Costs

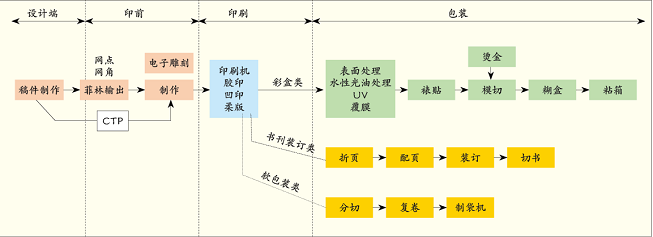

A supplier collaboration platform was established and connected with the ERP system to achieve online management of procurement orders, logistics tracking, and quality feedback across the full chain. Using the intelligent production platform system, logistics management cloud system, information data acquisition intelligent system, VR real-time system, and the 'one book, one code' identity authentication system, the company achieved a production capacity of 300,000 reams of paper, realizing a fully intelligent and digitalized production line from "materials intake ‑ prepress ‑ printing ‑ binding ‑ finished products ‑ warehousing".

Intelligent Printing Smart Control Panorama(2) One Code Traceability for Warehouse Management, Multi-Dimensional Matching to Improve EfficiencyBy using the "one item, one code" technology, each roll of paper is assigned a unique roll number. Through hardware devices such as ultra-wideband positioning base stations and industrial-grade barcode scanning data collection equipment, real-time data collection and dynamic tracking can be achieved throughout the entire process from warehousing, storage, to outbound. The system intelligently matches production schedules with multi-dimensional data such as paper specifications, remaining meters, and quality inspection reports, automatically generating the optimal picking plan to ensure precise alignment between paper and production plans. This enables intelligent barcode scanning for roll paper outbound and high-frequency, efficient inventory scanning.(3) Dual Intelligent Collaboration to Build Defense, Accurate Monitoring for Quality ControlThe online monitoring system for the perfect binding machine integrates high-speed cameras and high-precision scales, strongly ensuring printing quality. High-speed cameras can accurately align text during printing and quickly capture the position information of pages. If a misplacement is detected, an immediate alert is issued, effectively preventing disordered books and ensuring each page enters the binding process correctly. High-precision scales accurately detect abnormal page weights with high sensitivity, timely identifying and preventing missing or incomplete pages, controlling product quality from the source.(4) Equipment Interconnection Data Aggregation, Deep Analysis for Optimal SchedulingUsing a central processor communication module to connect various devices, data is collected via programmable logic controllers and uploaded to the controller, stored on an OPC unified architecture server, forming an organized data resource library. The collected data includes machine energy consumption, team energy consumption, real-time equipment comprehensive efficiency, and production line equipment comprehensive efficiency statistics. This data can be obtained by collecting vibration and temperature signals or by processing cloud-trained data deployed locally. Deep analysis of this data allows precise understanding of production capacity.Achievements and Highlights01/ Efficiency Innovation, Cost Control ExcellenceDriven by digital transformation, production efficiency increased by 35%, equipment utilization rose to 88%, and unit product energy consumption decreased by 18%. Through precise scheduling and resource optimization, annual production costs are reduced by over 15 million yuan, achieving simultaneous capacity enhancement and energy consumption reduction.02/ Intelligent Inspection Empowerment, Quality System UpgradeThe AI quality inspection system has been deeply applied, increasing product qualification rate to 99.1% and reducing customer complaints by 75%, with annual returns loss reduced by 2.6 million yuan. Smart technology fortifies the quality defense line and reshapes industry quality standards.03/ Green Transformation, Low-Carbon Development ExemplaryUsing a digital energy management platform, annual carbon reduction reaches 800 tons; optimizing production processes increases paper utilization by 5%, saving 4.2 million yuan in raw material costs annually, achieving coordinated growth of economic and ecological benefits.04/ Demonstration Leadership, Industry Empowerment ResponsibilityAs a benchmark for digital transformation in Shandong Province's printing industry, the company's experience was included in the "Shandong Province SME Intelligent Manufacturing Case Collection," attracting more than 30 peer companies for onsite observation.