Empowered by intelligent innovation, leading innovation and increasing efficiency! Shengtu Intelligent Three Core Launch, Shining China Prime 2025!

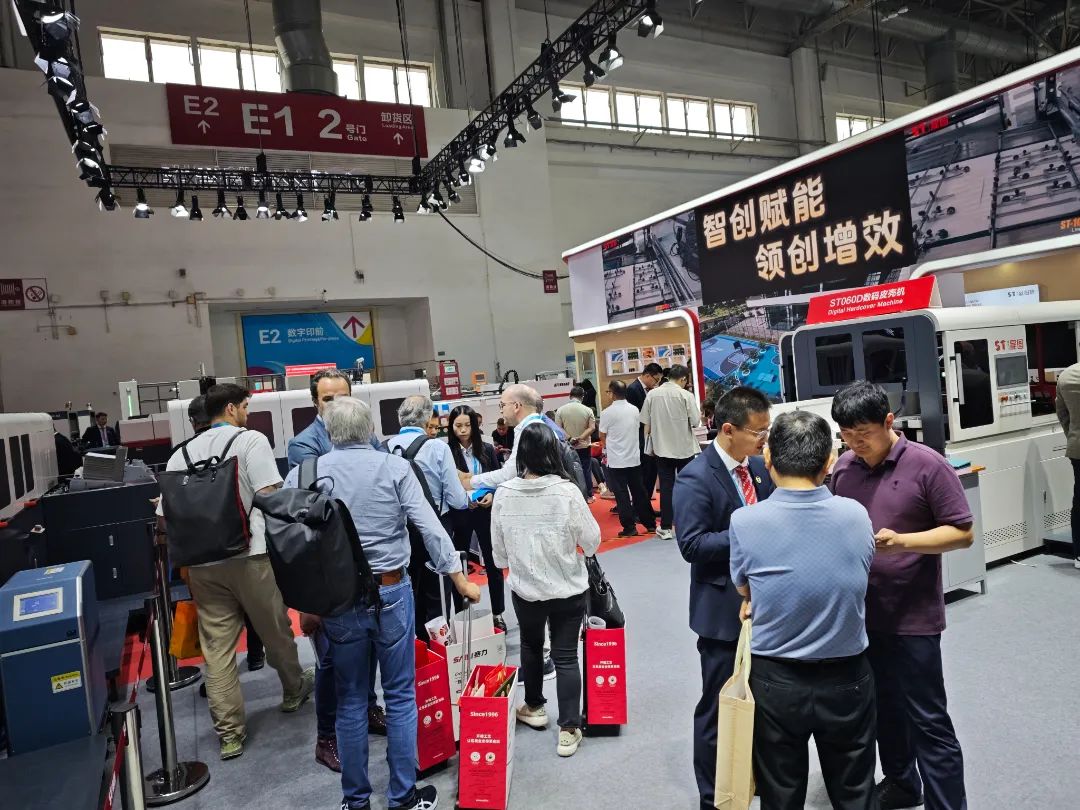

From May 15th to 19th, 2025, the global printing industry will focus on Beijing and participate in the 11th Beijing International Printing Technology Exhibition (CHINA PRIMT 2025) industry event. This exhibition has attracted over a thousand top companies from around the world to compete on the same stage. As a leading enterprise in the field of intelligent printing equipment in China, Shengtu Intelligence made its debut at booth E1-031 with an innovative attitude. With the theme of "Empowering with Intelligence and Enhancing Efficiency through Leading Innovation", it released three major global debut devices, comprehensively showcasing its latest intelligent manufacturing achievements and technological breakthroughs in the fields of printing and packaging, and surface efficiency improvement, showcasing the strength of China's intelligent manufacturing to the world.

Shengtu Intelligent has been deeply involved in the printing field for nearly 30 years, with strong research and development capabilities and sharp market insights. It has launched multiple industry benchmark products and holds over 100 core technology patents. Its products are exported to more than 80 countries and regions around the world. At this year's printing exhibition, Shengtu Intelligent once again broke through the boundaries of technology, launching three heavyweight equipment: the ST050AF pull folding box forming machine, the ST-1060AD magnetic levitation servo screen printing production line, and the ST-1050AH dual unit screen printing cold hot laser multifunctional production line. With cutting-edge technology and excellent performance, they became the focus of the entire event. Among them, the ST-1060AD won a special report from CCTV News, demonstrating the hard core strength of national brands!

The booth is extremely popular

Innovative achievements attract industry attention

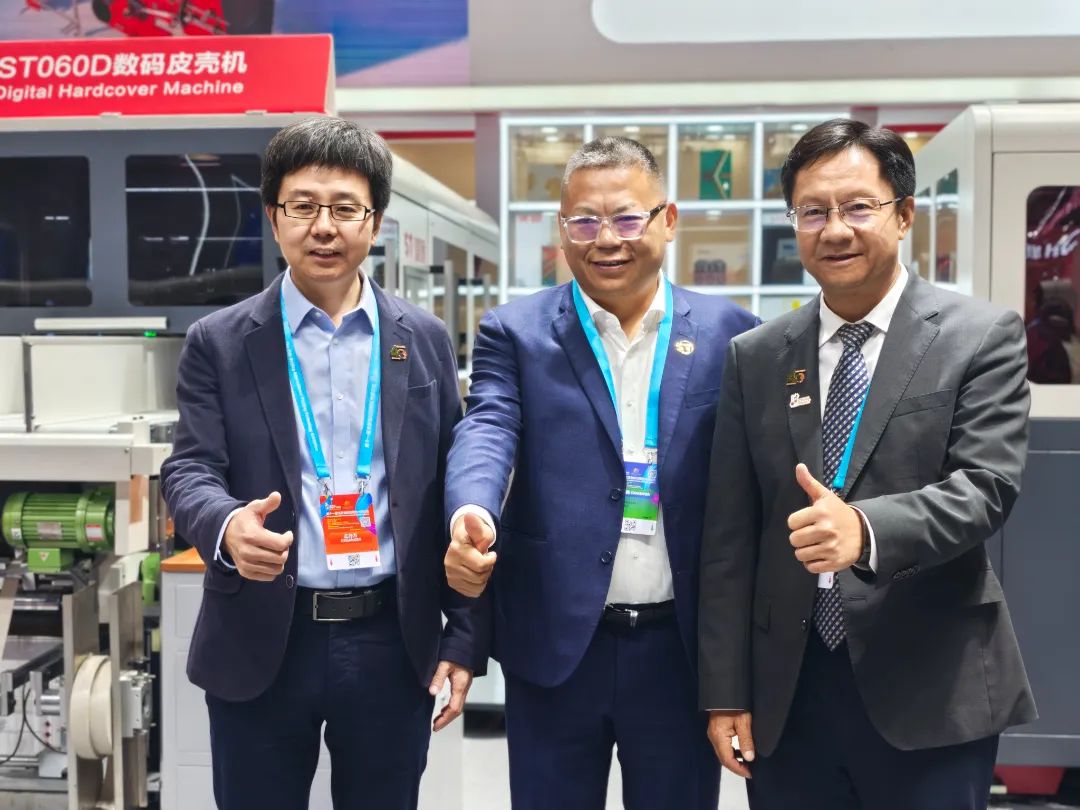

During the exhibition, Shengtu booth E1-031 was crowded with people, including representatives of printing and packaging companies, industry association experts, and media reporters from around the world. On site, the efficient, stable, and intelligent features of the new product are visually demonstrated through a combination of dynamic demonstrations and technical explanations. Visitors have shown strong interest in Shengtu Intelligent's new products and have praised its innovative technology and intelligent manufacturing concept. Many industry insiders have expressed that Shengtu Intelligent's new products not only excel in improving production efficiency, but also make significant progress in intelligence, automation, and technological innovation, injecting new impetus into the development of the printing and packaging industry.

Three major debut products

Leading industry technological innovation

01

New structure, new box type, new track--

ST050AF Pull type Folding Box Forming Machine

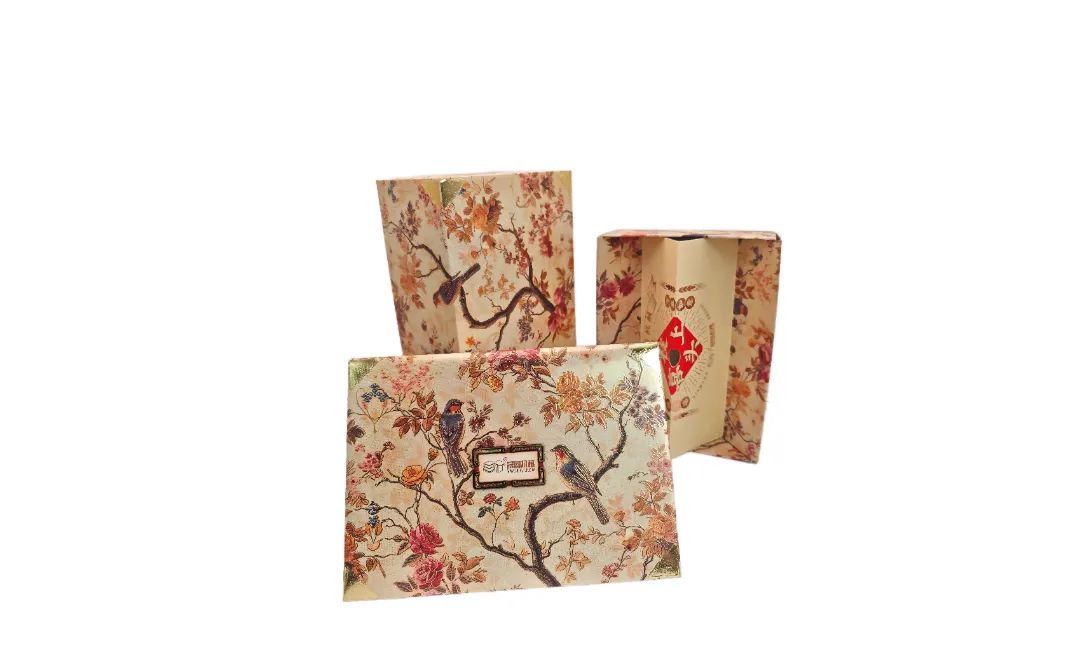

The ST050AF lifting folding box forming machine unveiled this time is an innovative work of Shengtu Intelligent to open the era of flexible and intelligent manufacturing of folding boxes, specially tailored for the lightweight folding box packaging market. By adopting space compression design and plug and play mode, compared with traditional sky and earth lid packaging boxes, it directly solves the problems of transportation and storage in traditional packaging, especially suitable for industries with high logistics costs and tight storage resources, such as footwear, clothing, e-commerce, food, electronic products, and luxury goods.

The unique pull up folding structure results in a finished product volume that is only 1/10 of the traditional box type, increasing the loading capacity of a 40 foot container by 8 times; Supporting the process of "production flat transportation terminal second group" to reduce the pressure of warehousing and transportation, this model will be combined with an intelligent warehousing system in the future, and its cost optimization potential will be further released, becoming a key innovation for reducing costs and increasing efficiency in the supply chain.

02

The ultimate balance between speed and accuracy--

ST-1060AD Magnetic Suspension Servo Screen Printing Production Line

The advancement from "mechanical transmission" to the "maglev era". The world's first screen printing production line using magnetic levitation direct drive technology, reported by CCTV, has zero mechanical friction, micrometer level accuracy, and a printing speed of 5000 sheets per hour. It is the first choice for high-end industries such as cigarette packaging, wine packaging, cosmetics, fine packaging, ceramics and glass paper, electronic components, etc. It can seamlessly connect with post-processing equipment such as cold ironing, snowflake wrinkles, UV curing, laser transfer, etc., to meet the one-stop production of high-end packaging such as cigarette packs and wine boxes.

The whole machine adopts a servo control system, which enables the machine to operate more accurately and stably. The mesh frame adjustment device adopts the latest German technology - magnetic levitation direct drive technology, which does not require gear and rack transmission, making the mesh frame accelerate and decelerate more quickly and smoothly, achieving full range ± 0.04mm dynamic printing accuracy, zero contact with the guide rail to achieve no wear, and the equipment has a longer service life, greatly reducing noise and vibration.

03

One machine with multiple capabilities, reshaping process boundaries--

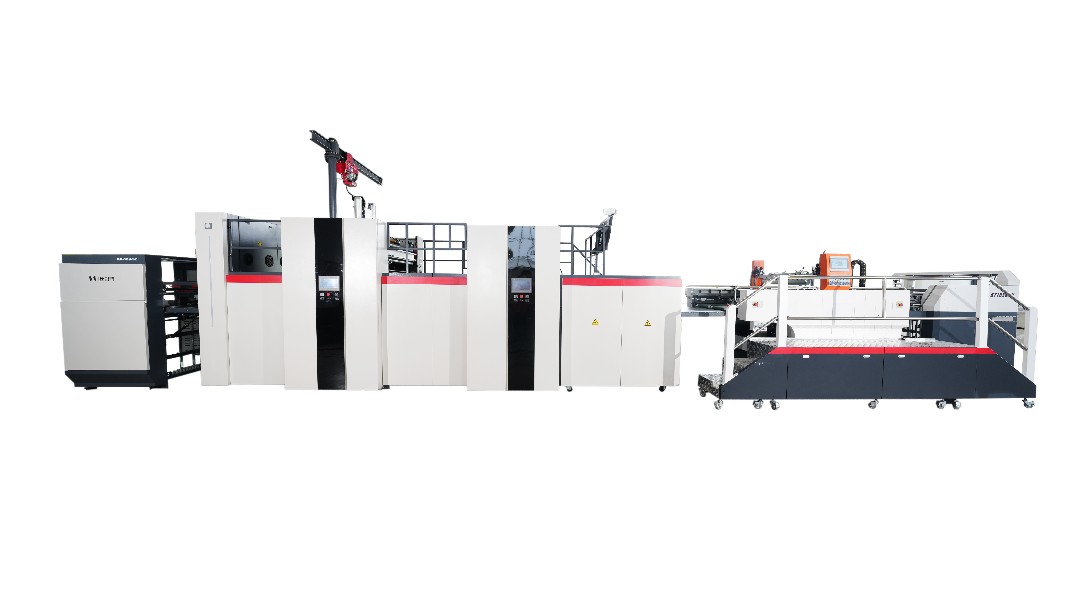

ST-1050AH Dual Unit Screen Printing Cold Pressing Laser Production Line

From "solo operation" to "joint operation", the ST-1050AH dual unit silk screen cold pressing laser production line is unique in the field of silk screen cold pressing. It is not only the only advanced production equipment on the market that can achieve two horizontal and multiple vertical cold pressing operations on the same paper, but also has excellent production capacity to support four rolls of different color cold pressing films at the same time, truly achieving one-time hot pressing molding, greatly improving production efficiency and product quality.

This production line integrates various cutting-edge new processes, including wrinkling, snowflake wrinkling, UV printing curing, electrochemical aluminum cold ironing process, and laser transfer, covering almost all high-end printing needs. With its powerful versatility, one production line can handle the functions of the past three lines, significantly reducing overall costs by 60%. By completing multiple printing processes in one place, the flexibility of production and the added value of products have been greatly enhanced, bringing higher economic benefits and market competitiveness to enterprises.

look into the future

Exploring possibilities through innovation

With the exhibition coming to an end, Shengtu&Sicaite's exhibition tour came to a perfect conclusion. But this is by no means the end, but the starting point of a new journey. The debut of three new products is not only a display of technological strength, but also a deep definition of the future of the industry. We sincerely invite global partners to inquire and negotiate, and explore the infinite possibilities of intelligent printing together!