Reduce manpower by 16% and save 3 million annually! Look at Jianfeng Printing's true efforts to reduce costs and increase efficiency

In the current era of deep integration between the digital economy and the real economy, the digital transformation of traditional manufacturing has become a necessary path to promote industrial upgrading and achieve high-quality development. Driven by the digital wave, Dalian Jianfeng Printing Co., Ltd. (hereinafter referred to as Jianfeng Printing) has risen from a regional traditional printing enterprise to a national benchmark for digital transformation industry with its forward-looking strategic layout and firm determination for digital reform. Through the nine-year digital long march, Jianfeng Printing Industry has achieved a magnificent transformation of digital transformation in the wave of industrial Internet.

Breaking Through: Embarking on the Path of Digital Development

Breaking Through: Embarking on the Path of Digital Development

Printing and packaging is a traditional labor-intensive industry, and many printing companies face challenges such as rising raw material and labor costs, and low production efficiency. As a traditional printing enterprise established in 1999, Jianfeng Printing mainly relied on manual operation and paper-based management in the early days, facing common problems such as low production efficiency, high costs, and large quality fluctuations.

Especially in high standard fields such as color printing packaging, customers have increasingly stringent requirements for product quality and delivery efficiency. Yang Sixia, General Manager of Jianfeng Printing, recalled, "There are countless printing companies like Jianfeng Printing across the country. How can we break through the situation in the future, stand out in the industry, and meet the increasingly high-end needs of customers? I gradually realized that digital transformation is urgent

Previously, Jianfeng Printing Industry had three failed experiences of digital transformation, and the company's internal attitude towards digitalization can be described as' turning pale '. At that time, there were three major obstacles facing Jianfeng Printing Industry: firstly, there was not enough digital talent team; secondly, the management software on the market could not perfectly replace the operating mode at that time; thirdly, the investment in digital transformation was relatively high.

It is widely believed that the new CEO wants to make some achievements, but the cost is too high! Jianfeng Printing is simply not suitable for digitization. However, Yang Sixia firmly believes that "digitalization is definitely the trend and the 'top leader' project. With the support of rational judgment and super strong execution, it is worth a try

Under questioning and heavy pressure, Jianfeng Printing Industry began a "last ditch battle". In 2017, Jianfeng Printing Industry officially launched its digital transformation project, gradually achieving a leapfrog development from "workshop style" management to intelligent production through the integration of digitalization and green development, driven by technological innovation and management change.

Jianfeng Printing Factory

Concept: Establish the transformation goal of "Industrial Internet+Green Packaging"

Concept: Establish the transformation goal of "Industrial Internet+Green Packaging"

In the early stage of digital transformation, Jianfeng Printing Industry proposed a top-level development strategy of "Industrial Internet+Green Packaging", emphasizing the integration of digitalization and greening in the process of transformation.

Our overall plan is to roughly divide the digital project into three stages, "Yang Sixia explained in detail. The first stage is mainly to carry out the company's standardization construction through information technology. By introducing leading domestic management software such as CRM, PLM, CAD, ERP, etc., the standard system of Jianfeng Printing Industry is reshaped, and various data that relied on experience and manual recording in the past are entered into the system in a unified standard, laying the foundation for digitalization.

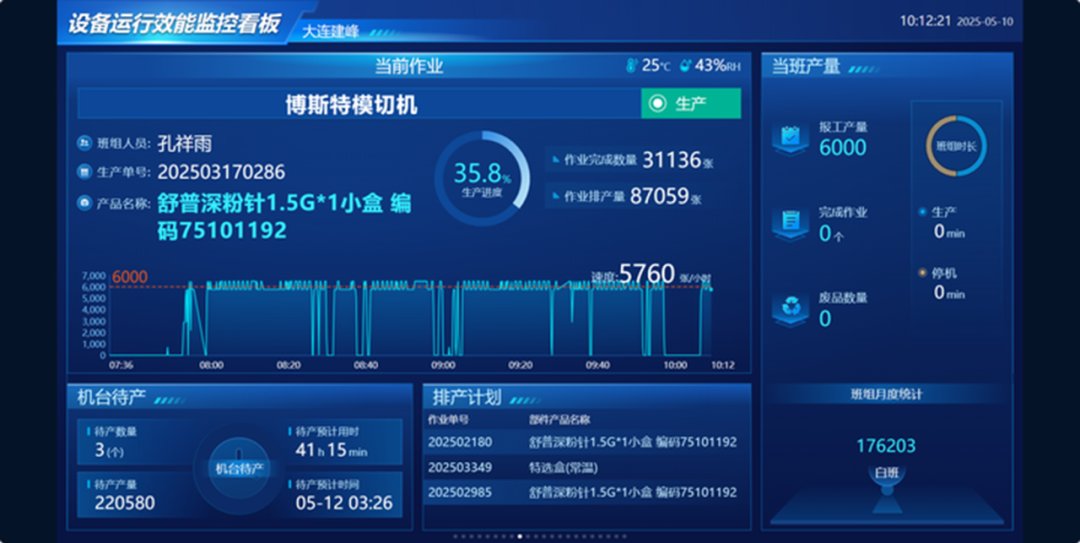

The second stage is to introduce MES system and implement digital transformation of the production process. By using IoT technology to collect key parameters of devices and upload them to the platform, the production equipment and management platform, software and hardware are deeply integrated, making the devices "live" and achieving data interconnection and real-time collection and analysis.

The third stage is to enable digital transformation with 5G technology, build a unified "5G+Industrial Internet" platform, and realize intelligent management of design, production and storage.

Jianfeng Printing Industry Digital System

Jianfeng Printing Industry Digital System

"Each stage is closely linked and mutually supportive, and jointly promotes Jianfeng Printing to move steadily towards the goal of 'industrial Internet plus+green packaging'."

In the first stage, through the construction of information technology, Jianfeng Printing's management system became more standardized and data became more accurate, which not only improved work efficiency but also laid a solid foundation for subsequent digital transformation. The introduction of MES system in the second stage has enabled the transformation of the production process from extensive management to refined management, making the production process more transparent, significantly improving equipment utilization and production efficiency, while reducing energy consumption and waste rate, and achieving green production. In the third stage, the empowerment of 5G technology will promote the comprehensive improvement of operational efficiency and overall competitiveness of Jianfeng Printing Industry.

Practical Action: Breaking through Transformation Difficulties Step by Step

Practical Action: Breaking through Transformation Difficulties Step by Step

Digital transformation is not something that can be achieved overnight, nor is it simply the procurement of software and hardware. It is a reform of the enterprise management system that requires distributed promotion and tackling difficult problems one by one. We match the needs of digital transformation by reshaping the standard system, business model, and organizational structure, "said Yang Sixia.

In the stage of information deployment, Jianfeng Printing Industry first started with a small incision in the "OA system", and achieved "paperless" daily office by setting up online attendance and approval processes, allowing employees to understand the convenience of digitization. The new system has improved approval efficiency by over 80%, reduced attendance statistics from three days to five minutes, and utilized low code to build customized reports, enabling real-time analysis of procurement, inventory, and sales data. Decision response speed has been increased by 40%.

In 2020, Jianfeng Printing invested in the introduction of an ERP enterprise resource planning system, achieving full process integration from sales orders to product delivery.

Jianfeng Printing Industry Digital System

Jianfeng Printing Industry Digital System

Digitization has changed the inherent work methods and processes of employees, so some employees may initially have resistance. We adopt a flexible persuasion strategy, personally demonstrate it to them, and continuously communicate with engineers if there are any problems, polishing the ERP system that is truly suitable for Jianfeng Printing industry. At first, the management and employees did not have sufficient confidence in the ERP system, walking on two legs while using paper work orders and platform systems, which actually added to their workload. Later on, everyone gradually got used to digital systems, and everything went back on track. "

Entering the second stage, Jianfeng Printing Industry will update its printing equipment and promote production automation and intelligence; On the other hand, leading system service providers in the collaborative industry have introduced business software such as MES systems and CRM customer relationship management systems. Through the integration of new generation information technology and manufacturing industry, multiple systems are integrated to eliminate data silos, build a data center, and achieve visual management of production status.

In order to ensure the true implementation of digitalization, Yang Sixia personally participated in the promotion work from front to back, went deep into the front line, and listened to the real feedback of employees. Small and medium-sized enterprises generally have weak digital foundations, but the high cost of transformation and weak trial and error capabilities make many small and medium-sized enterprises hesitant to embrace digitalization. Therefore, digital transformation must be regarded as the 'top leader' project of the enterprise, and the top leader must deeply participate in the project to ensure its smooth implementation

After the first two stages of digital construction, Jianfeng Printing has significantly improved its production efficiency and product quality, reduced the number of employees by about 16%, and saved the company nearly 3 million yuan in labor expenses annually. At present, the digital construction of Jianfeng Printing Industry is in the third stage, which will deeply apply 5G technology to empower quality inspection, equipment operation and maintenance, intelligent warehousing and other application scenarios, and strive to build a national leading intelligent factory.

With the courage to take the lead and years of active exploration in digitalization, Jianfeng Printing Industry has gradually grown from a traditional small and medium-sized printing enterprise to a national demonstration enterprise for the integration of new generation information technology and manufacturing. It has been awarded multiple honorary titles such as National High tech Enterprise, National Green Factory, Liaoning Province "Specialized, Refined, Unique and New" Little Giant Enterprise, Liaoning Province Intelligent Factory, and Liaoning Province Digital Transformation Benchmark Enterprise.

Digital transformation is never a multiple-choice question, but an urgent and necessary answer. Through strategic foresight and hard work, small and medium-sized traditional enterprises can also stand at the forefront of the digital wave. Jianfeng Printing has gone from small workshops to smart factories, and is now moving from a corner of Northeast China to the national stage.