Beauty packaging material leader, Shengqi's global breakthrough path

Here, there is a company that holds honorary titles such as "National High tech Enterprise", "Famous Trademark of Zhejiang Province", "Ningbo Famous Brand Product", "Zhejiang Export Famous Brand", and "Leading Enterprise in Zhejiang Province's Foreign Trade Integration".

It is Zhejiang Shengqi Industrial Co., Ltd. (hereinafter referred to as "Shengqi"), which has extensive experience in the research and development, production and manufacturing of cosmetic packaging products, and has formed a complete industrial chain integrating product research and development design, precision mold manufacturing, automated injection molding (central feeding system), and automated assembly.

5 injection molding machines to a 100000 square meter intelligent manufacturing base

Decoding Shengqi's Path to Global Breakthrough

Shengqi enjoys a high reputation in niche markets such as plastic bottles and pump heads.

In 2006, in Yuyao, Zhejiang, 7 employees and 5 injection molding machines embarked on the entrepreneurial journey of Shengqi. Who would have thought that this private enterprise, which started from scratch, has grown into a benchmark in the cosmetics packaging industry with a daily output of 3 million pump heads and 1 million cosmetics after 19 years of innovation and change. Its development trajectory not only reflects the upgrading and leap of China's manufacturing industry, but also represents the high-quality development of "specialized, refined, unique and new" enterprises.

In the early stages of entrepreneurship, Shengqi anchored its "quality based enterprise" strategy and was the first to obtain ISO9001 international quality system certification in 2007, laying the foundation for subsequent development. With the commissioning of the second factory in 2013, the company achieved its first breakthrough - being awarded the title of "National High tech Enterprise" and entering the ranks of growth oriented small and medium-sized enterprises in Zhejiang Province and technology-based enterprises in Ningbo City. At this point, Shengqi has shifted from traditional processing to technology driven transformation.

Under the guidance of the "Made in China 2025" strategy, Shengqi has embarked on a comprehensive upgrade: it was awarded the title of Ningbo Patent Demonstration Enterprise in 2014, established a provincial-level enterprise engineering technology center in 2015, and passed ISO14001 environmental management system certification in 2016, forming a "green intelligent manufacturing+intellectual property" dual engine. With the completion of the third and fourth factories and the development of PET bottles, its annual output value exceeded 310 million yuan in 2018.

Faced with the challenges of the post pandemic era, Shengqi has broken through with innovation. In 2021, the provincial-level high-tech enterprise R&D center was established and won titles such as the Ningbo Science and Technology Achievement Award and the Top 10 Demonstration Enterprises for High quality Development of Manufacturing Industry; In 2022, the 110 acre smart park will be put into use, further increasing production capacity. At present, the company's products are exported to Europe and America, with a market share of 50% both domestically and internationally. The dual certification of "Zhejiang Export Famous Brand" and "China Foreign Trade Export Leading Index Sample Enterprise" confirms the success of its globalization strategy.

Based on high-end

Build a dual engine of "technology+intelligent manufacturing"

Standing at the starting point of the second new decade, Shengqi is redefining the industry boundary with the concept of "intelligent styling service provider". From following to leading, this Zhejiang enterprise has interpreted the profound connotation of "specialization, refinement, uniqueness, and novelty" in sixteen years - using technological innovation as the pen and craftsmanship as the ink, writing the star sea of Chinese manufacturing in every inch of cosmetics packaging.

In the value coordinate of the cosmetics industry chain, Shengqi uses the "two wheel drive" strategic precision positioning core track: on the one hand, it relies on the "pump head+bottle" cleaning and packaging basic plate to establish scale advantages; on the other hand, it takes the technological highland through the innovation of functional skin care packaging materials, forming the whole industry chain service capability covering daily chemicals to professional cosmetics. The main products are lotion bottles, vacuum bottles, cream bottles, etc.

In the face of the explosive growth of the hair care market, Shengqi focuses on "scalp care ingredients and precision atomization technology", develops a continuous spray system, realizes the micron level uniform spray and effective ingredients long-term stability, can continue to press, soft atomization, and meet the needs of high-frequency use.

Behind this technology is Shengqi's long-term investment in research and development. It is reported that Shengqi develops 600 sets of molds every year, of which more than 50% are private molds specially customized for customers. From basic care to effective skincare, Shengqi Packaging is reconstructing the value chain of beauty packaging materials through technological iteration. At present, the total area of Shengqi factory has exceeded 130000 square meters, with more than 350 injection molding machines, over 400 automated assembly equipment, and 290+patent certificates, successfully supporting the high-frequency new product development needs of beauty brands and contract factories.

With the continuous development of the dual engines of "technological barriers+flexible intelligent manufacturing", Shengqi has partnered with over 60 well-known cosmetics companies, including Unilever, Procter&Gamble, Colgate, Huaxi Biotech, Naturals, Botany, Shanghai Jahua, and Baique Ling, to provide personalized customization services and accurately meet customer needs.

Create a model for the transformation and upgrading of "specialized, refined, unique, and new" enterprises in the wave of domestic substitution. With the diversified evolution of packaging material demand in the new consumer era, this hidden champion's deep cultivation of the track may redefine the global competitiveness of China's cosmetics supply chain.

Winning by quality

Strategic partners of high-end brands

Shengqi has always adhered to the concepts of innovation and environmental protection, with quality as the core management principle, and driven sustainable development of customers through continuous research and development innovation.

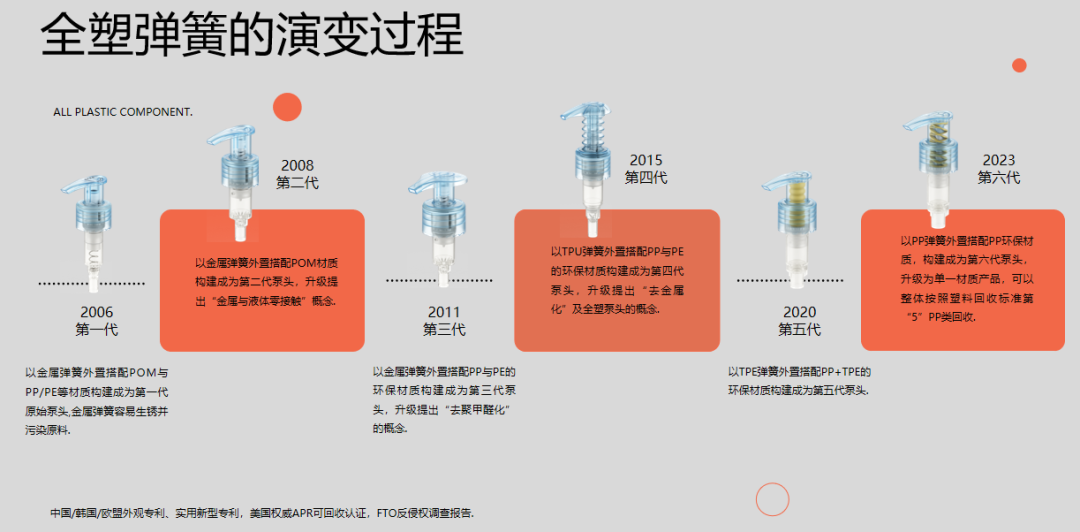

At present, its pump head spring has innovatively iterated from TPU and TPE to PP material, and has crossed from metal pumps to metal free all plastic pumps. In 2023, Shengqi successfully developed a single material all plastic pump series and quickly applied it to the skincare series, enriching the product specifications to meet the different needs of customers.

Not only that, in recent years, Shengqi has been adhering to the concept of sustainable development to lead innovative packaging design, focusing on both material innovation and design reduction. It is committed to achieving easy recycling, compostability, and reusability of cosmetic packaging materials; At the same time, it also reduces weight, space, usage, and emissions of the product.

After layers of iteration and continuous innovation, Shengqi's application of environmentally friendly materials has become quite mature.

In terms of PCR low-carbon regeneration technology innovation, Shengqi adopts post consumer recycled plastic (PCR) and PP/PE/PET raw material composite modification technology, which can be further processed to manufacture new packaging materials and effectively promote the recycling of waste plastics.

In terms of the single material structure revolution, Shengqi has built the sixth generation pump head by combining PP springs with environmentally friendly PP materials, upgrading it to a "single material product" and recycling it according to the "5th" PP category of plastic recycling standards.

In terms of modular replacement system, Shengqi reduces the use of plastic by replacing the inner liner and reusing the outer bottle.

In terms of advanced applications of bio based PET, PET substrate, as a renewable material, can be applied to various product categories, with good recyclability and reusability, which can reduce the consumption of natural resources and environmental pollution. Shengqi meets the brand's sustainable development needs for de sulfurized substrates through the effective use of PET substrates.

Driven by the dual trend of green consumption and the upgrading of global ESG standards, Shengqi's exploration proves that the innovation of beauty packaging materials has surpassed the simple function of containers and is evolving into a key hub connecting ingredient formula science, consumer experience, and sustainable development of the earth. This innovation that combines technological sharpness and ecological warmth may be the best example of China's manufacturing shift from cost advantage to value creation.

At the same time, Shengqi leads industry innovation with the "technological intergenerational gap", builds an agile innovation system with continuous R&D investment intensity, quickly achieves iterative updates of new materials and processes, and updates the pace of new products, helping customers shorten the new cycle of environmentally friendly products, and continuously refreshes the sustainable standards of beauty packaging with innovative capabilities beyond the previous layout.