Fangzheng Jieying Inkjet with Leading System Technology

After last month's China Print 2025, China's inkjet rotary printing equipment experienced another wave of sales surge, resulting in the equipment supply period being extended from 30 days to 45 days or even 60 days. Why did Fangzheng's inkjet rotary equipment repeatedly trigger a surge in sales of inkjet equipment in China after 2019? The following analyzes the reasons for the resurgence of Fangzheng inkjet equipment from the perspectives of business logic and technological advantages.

Analytics

Reviewing the Explosion of Inkjet Spinning

2019 is widely recognized as the first year of the development of inkjet printing in China, and there are two important reasons why inkjet rotary printing can fully explode in China. On the one hand, after 14 years of research and development and technological accumulation, Fangzheng Jieying Inkjet Rotary has comprehensively upgraded its product design, surpassing the "singularity" in printing quality and stability. The printing quality is completely comparable to international brands such as Japan and the United States, which has made the inkjet rotary printing quality made in China widely recognized by the industry. On the other hand, Fangzheng adheres to the concept of "creating value for users", significantly reducing the entry threshold and usage cost of inkjet rotary printing equipment, making it affordable, usable, and profitable for many private enterprise users.

Although inkjet rotary printing originated from digital printing of direct mail receipts and was planned as a POD for on-demand book publishing, in China, the explosion of inkjet rotary printing was due to business on-demand and educational printing. On the one hand, China has leading enterprises like Fangzheng that shoulder industry missions and have been tirelessly exploring cutting-edge technologies in the industry; On the other hand, there are unique printing market opportunities in China. When the dual effects of technological maturity and market opportunities overlap and stack, new sparks will collide and give birth to new industry mutations. Therefore, in 2019, Fangzheng inkjet technology was excellent, the entry threshold was appropriate, and the business logic was clear, which led to the comprehensive outbreak of inkjet rotation in China.Choose to gradually return to rationality

After six years of rapid growth, domestic brands have sprung up like mushrooms after inkjet rotary printing. Many industry related companies have rushed into the sub field of inkjet rotary printing, and many manufacturers believe that they can manufacture inkjet rotary printing equipment and share the pie of inkjet rotary printing. How do you know that when you enter the inkjet, it's as deep as the sea, and looking back, it's difficult to get out of it all. It's not difficult to create an inkjet rotary device, what's difficult is to make a good device, and what's even more difficult is to only realize that the color machine is the protagonist after building the black and white machine.

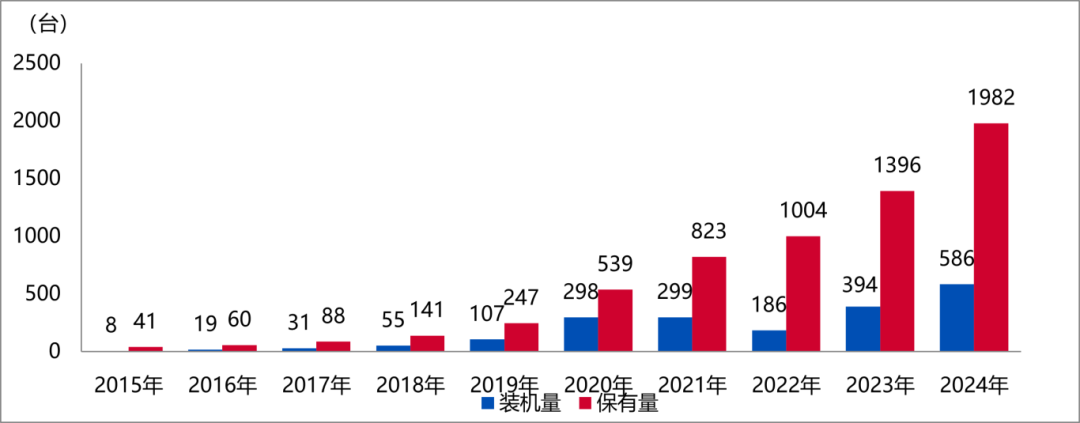

Data on the installation of inkjet rotary machines in China from 2015 to 2024

Data on the installation of inkjet rotary machines in China from 2015 to 2024

For many domestic inkjet brands, many companies have not conducted systematic market research and industry analysis before entering the market. After entering the industry, I realized that inkjet rotary printing is not as single and pure as the printing and dyeing industry, industrial inkjet printing, or inkjet coding industry. Overall, inkjet rotary printing is a printing sub field mainly focused on paper inkjet printing, with its core products being book and commercial printing.

But who knew that the necessary conditions for manufacturers of book and magazine printing systems are pre press software systems+printing production systems (which can also be subdivided into printing and cutting).

Pre press software may sound simple but difficult to implement, otherwise why do domestic pre press software suppliers only have Fangzheng leading the way? It's because prepress software technology cannot be mastered overnight. The reason why Fangzheng can become a supplier of Chinese prepress systems is because it once shouldered the historical mission of successfully inputting Chinese characters into computers, and later broke through the international manufacturer's blockade on prepress technology, developing RIP technology with Chinese parsing as its advantage. This established the identity and role of a Chinese prepress software system supplier. For 40 years, Fangzheng has been deeply cultivating prepress software technology and cutting-edge industry technology. Therefore, Fangzheng leads inkjet technology with a natural advantage in prepress technology. Meanwhile, with the increasing maturity of inkjet technology, Fangzheng has been exploring the latest applications of inkjet technology and the overall system control technology for inkjet printing. Combined with the introduction of internationally leading continuous paper cutting technology, Fangzheng has become the only inkjet rotary system manufacturer that can master a complete set of core technologies including prepress software, inkjet control, and post press slitting. Therefore, while other entrants are still cheering that they can print black and white images and text, Fangzheng has already made the black and white printing equipment more mature and stable. At the same time, it has quietly pushed the industry into a higher dimensional color inkjet printing track.

Traditional printing factories, as experienced industry equipment users, naturally choose equipment with industry experience and brands. But in order to quickly enter the market, the graphic and text fast printing store, which had never had a quality inspection process, wanted to add POD, and from then on, the store manager became the factory manager. Therefore, some blind adventurers choose low-priced and non branded inkjet printing equipment. After using it for a while, I realized how important the stability and convenience of production equipment are. Why does POD printing require higher equipment stability than traditional printing? This is mainly because POD emphasizes a delivery time, and a fast delivery time can reflect the value and price of digital products. Therefore, after placing an order, equipment failure or insufficient stability can cause great suffering for producers. Over time, delayed shipments and unstable quality will seriously affect the business and profits of the enterprise. Therefore, when many companies repurchase POD equipment, they will consider choosing branded equipment. From black and white machines to color printing machines, it is inevitable that various brands choose Fangzheng equipment when purchasing equipment again.

After going through the initial trial of black and white inkjet rotation and the subsequent pitfalls of color inkjet rotation, all these painful industry experiences have left scars or deep memories for these small brand buyers without exception. Therefore, after 6 years of market testing or personal experience of inkjet rotary brands, many entering enterprises have gradually become more rational and mature from the initial stage of mixed black and white inkjet rotary to color inkjet rotary. Therefore, the scene of a surge in orders for Fangzheng's entire inkjet equipment has emerged.

Next, from the perspective of products and technology, we will analyze why only Fangzheng is a reliable and stable inkjet rotary printing system.

technical analysis

Professional prepress process software

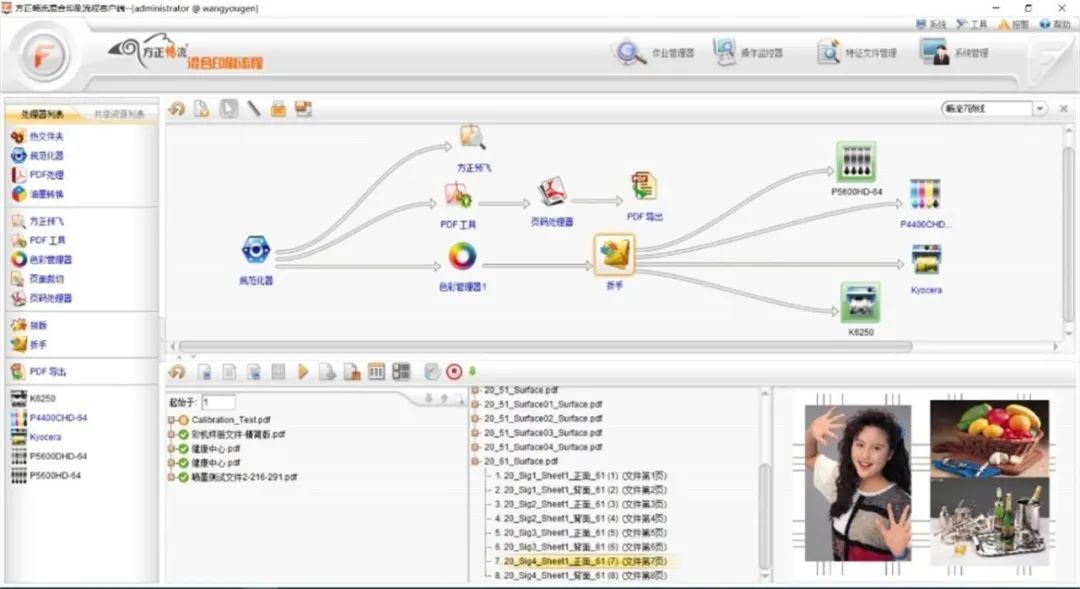

Compared with the software systems of other domestic inkjet brands, Fangzheng Changliu has automated process software and simple software for typesetting and printing drivers. The difference is like the difference between purchasing prepress CTP with process software from 2005 to 2010, and whether there is no process software or manual typesetting. Enterprises without pre press production experience cannot distinguish between having pre press process software and only having pre press typesetting.

If you have professional pre press process software, pre press file production is just a routine setting. Many pre press file processing can be automated and batch processed using dedicated functional modules in the process software. In this way, for an inkjet rotary printer, the captain can use process software to batch process files during printing for pre press inspection of printing formats, and call dedicated typesetting templates for automatic typesetting of various binding methods. And automatic addition of white pages, one click selection of post press marks.

Overall, the use of prepress process software enables batch archiving, job management, batch processing, and automated job processing, greatly improving the efficiency and security of prepress document processing. And only the system of splicing software requires specialized manual processing and inspection, and its efficiency and security are completely different dimensions. Taking the conversion of color files to black and white and four-color characters to single black as an example, having process software is a fully automated production process. If there is no automation, it needs to be completely manually processed.

Black and white inkjet rotary processing of color original files.

In inkjet rotary printing systems, it is common to encounter the situation where color files are directly converted to single black printing. This is a common setting in Fangzheng Changliu, but in other domestic systems, a dedicated person is needed to handle the file before printing. In this way, not only does it increase personnel costs and working hours, but it also increases the probability of file modification errors.

Business color inkjet rotary encounters four-color text.

In traditional printing factories, this is already a pre press production and inspection process. However, in the inkjet era, many fast printing shops lack industry experience and believe that printers can print four-color characters. However, for small texts with high quality requirements, it is a disaster. Pilots often need to spend a certain amount of time debugging and aligning, in order to reduce the printing problems that are prone to occur with small and micro four-color characters. They may never know that this is not a production debugging issue at all, but a design problem of standardized processes for prepress processing. Difficult for the captain, reduced production efficiency and quality.

Comparison of Overprint Error in Direct Printing of Four Color Characters and Automatic Conversion of Four Color Characters to Single Black Printing Effect

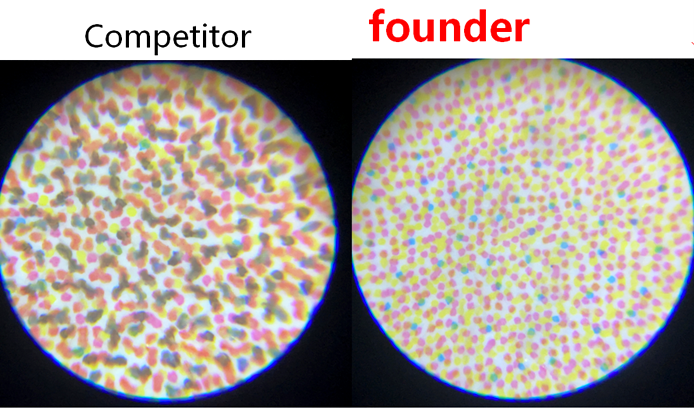

Fangzheng Multi channel Deep Frequency Modulation and Intelligent Ink Droplets Enhance the Sampling Effect of Copperplate Paper

Many new entrants may not be aware that Founder, Harlequin, and Adobe are the three major RIP manufacturers in the global printing industry. Entering the inkjet era, only Fangzheng is the only inkjet rotary equipment supplier with independent RIP technology. Therefore, compared with international inkjet rotary manufacturers such as Kodak, HP, Ricoh, Screen, Canon, Gongyao and many other international brands, Fangzheng's systematic advantages become more significant. As we all know, the core factors that affect the final quality of inkjet rotary printing are on the one hand the nozzle technology, and on the other hand the pre press RIP technology and frequency modulation screening technology. Only with the independently controllable RIP technology and in-depth research and development of frequency modulation screening suitable for unique inkjet inks and local paper under comprehensive conditions, can water-based ink achieve both color saturation and fast drying without wrinkling on ordinary paper. Therefore, it is necessary to achieve comprehensive control and optimal effect of RIP+frequency modulation and screening+color management+Total Ink.

At the initial stage of 600dpi color inkjet printing, a total ink volume of 180 or more for two colors can cause severe paper wrinkling, even more severe than a total ink volume of 240 for three colors. This is almost an irreconcilable contradiction between total ink volume and saturation in color management. Therefore, after multiple rounds of network algorithm optimization and total ink volume control optimization, Fangzheng finally found color management parameters that can achieve a total ink volume of 240 and also achieve paper drying without wrinkles.

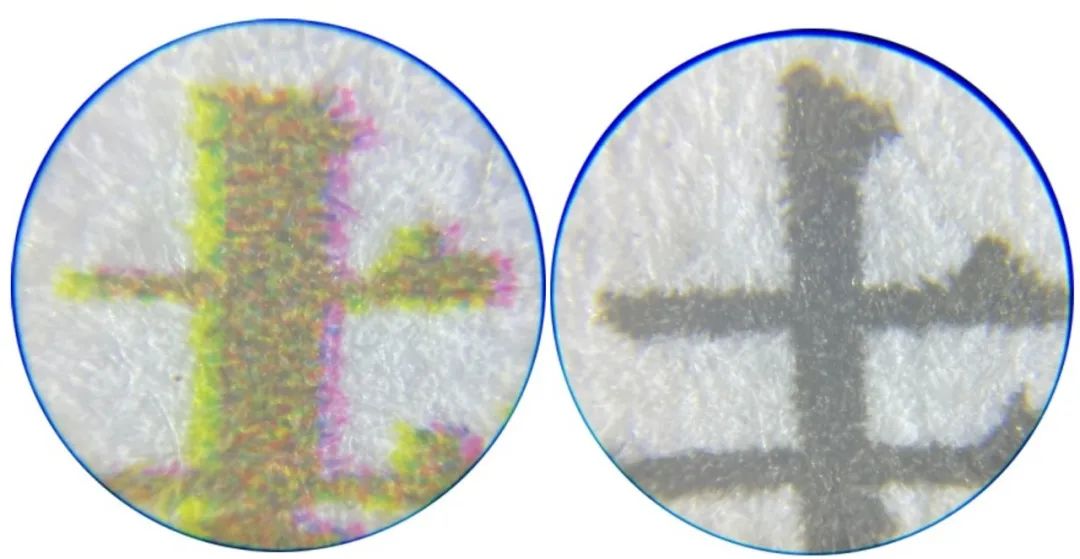

Comparison diagram of ink spot optimization on copperplate paper

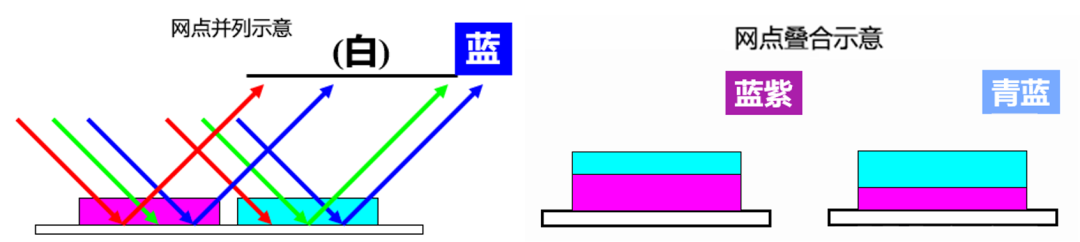

Comparison of the effect of overlapping branches to parallel branches

Comparison of the effect of overlapping branches to parallel branches

According to the principles of printing color theory, theoretically, colors formed by the same color value are the same, but the difference in transmittance of different inks can result in better dot alignment than dot stacking. Dot stacking is related to ink transparency, ink layer thickness, and stacking order, which can result in color cast and saturation decrease.

Analysis of the principle of parallel and overlapping branches

Analysis of the principle of parallel and overlapping branches

Fangzheng's copperplate printing has always been based on the characteristics of domestic paper and the dual practical conditions of no pre coating, tested and adjusted under actual usage conditions. Therefore, in the era of inkjet printing, Fangzheng is the only inkjet system supplier with complete software independent research and development capabilities and ink research and development capabilities. The optimal system parameters for comprehensive matching of ink and paper suitability under the conditions of domestic copperplate paper have been achieved through pre press RIP, inkjet specific multi position deep frequency modulation screen, as well as CMS color separation and total ink volume control.

Drying and flattening techniques for copperplate paper after printing

Recently, the domestic printing market has been heated up by copperplate paper printing, resulting in a shortage of machines after the exhibition, and everyone is waiting for the equipment to be shipped and installed. On the one hand, since the first installation of Fangzheng P6600CHD-33 in June 2024, Fangzheng inkjet rotary printing can replace toner digital or indigo for business printing. Some foreign agents jokingly call P6600CHD-33 the killer of electronic ink equipment, because they see that the quality of Fangzheng's inkjet samples is not inferior to electronic ink equipment. This application, taking Luoyang Meitu as an example, completely ignited the rapid application of inkjet rotary printing in the field of business printing. Combined with the strong promotion and precise push of self media, this application has been rapidly promoted and popularized. Afterwards, orders for only the P6600CHD-33 model from Fangzheng exceeded 20 units in less than half a year.

On the other hand, traditional business printing enterprises in China have begun to replace traditional offset printing with copperplate paper inkjet rotary printing. Taking Beijing Jingcheng Printing as an example, before they purchased copperplate paper printing equipment, they never expected that the transfer of inkjet rollers would bring them a 30-40% increase in traditional business orders. At present, Fangzheng inkjet rotary printing equipment can meet over 90% of the commercial printing needs for copperplate paper. Therefore, they originally used traditional offset printing as their main equipment, but now with the addition of a Fangzheng Jieying P4400CHD 4.0 pro, their business orders have been shortened from 72 hour delivery to 24 hour delivery, causing the entire business order to come pouring in like snowflakes. From a market perspective, users are willing to pay for timely delivery, which has taken traditional printing rolls to a new level of domestic inkjet rotary business order taking. After installing the first P4400CHD 4.0 Pro, Beijing Printing decided to move the entire traditional printing equipment to the Tianjin factory and transform the Beijing factory into a pure digital inkjet rotary factory. In the future, the Beijing digital factory will only produce ultra urgent business orders with a delivery time of less than 24 hours.

The core requirement for meeting these business printing needs is to meet the printing quality standards of copperplate paper and ensure stable production. Previously, one of the problems that plagued inkjet rotary copperplate paper printing was the flat wire drawing and the formation of waves and unevenness on the paper after printing. At present, Fangzheng has thoroughly improved the problem of flat wire drawing through frequency modulation network optimization. At the same time, by using specialized drying and paper wetting and flattening equipment, the problems of paper swelling and ink cracking during ink drying caused by high-temperature drying of copperplate paper and ink drying, as well as the problems of waves and unevenness after paper drying, have been solved in one fell swoop.

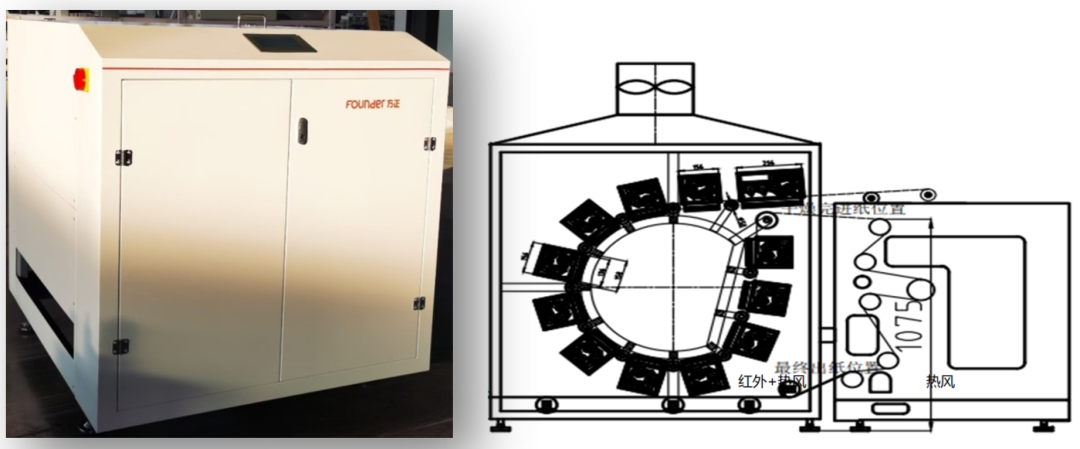

Copperplate paper drying and flattening device

Copperplate paper drying and flattening device

Therefore, after conducting numerous drying tests and post press hydration tests based on ordinary adhesive paper, Fangzheng independently developed devices for re wetting and flattening after drying. Therefore, it greatly improves the color quality effect and paper flatness recovery after drying.

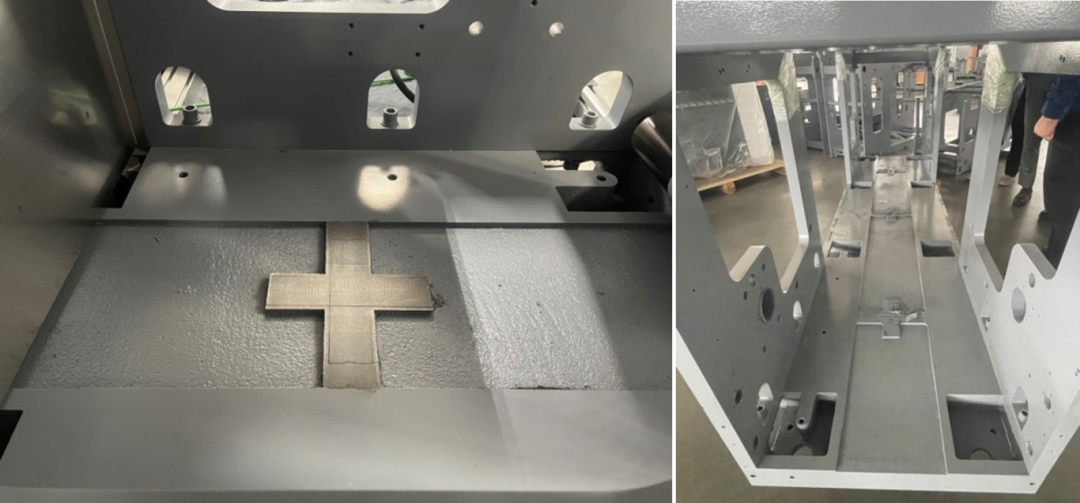

Advantages of Casting Platform

In general, large precision mechanical equipment needs to choose casting structures as its mechanical platform and frame structure in order to achieve high precision in production operation. Therefore, in order to manufacture high-precision mechanical platforms and prioritize technical requirements, Fangzheng decisively chose the highest cost casting structure. By utilizing the advantages of the casting structure, the stability of the entire mechanical platform operation is ensured from the design end and principle, and the four-color registration accuracy of high-speed printing is also guaranteed.

Fangzheng Jieying Casting Platform Structure

Fangzheng Jieying Casting Platform Structure

Fangzheng's unique circulating ink supply system

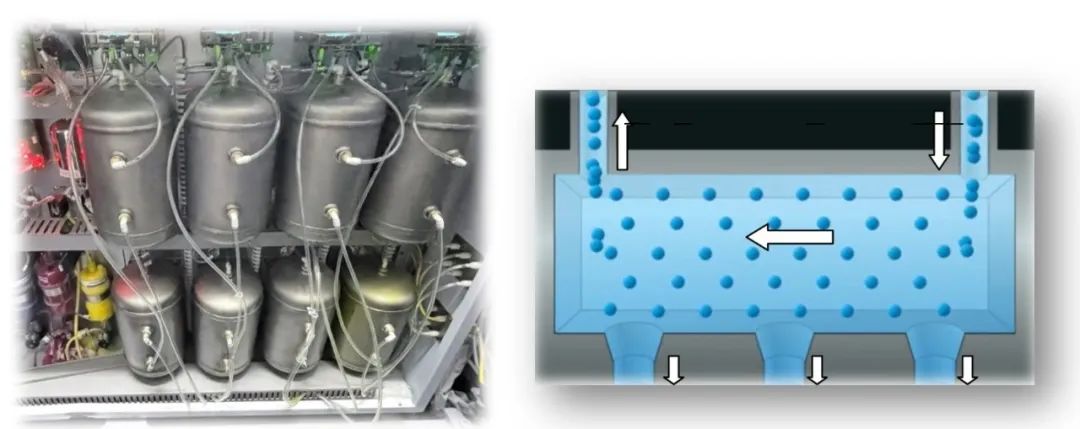

After receiving feedback from numerous users, Fangzheng has independently developed its unique circular ink supply technology. In principle, this type of ink supply is to apply a circulating pressure to the ink in the nozzle to reduce bubbles in the ink, so that the ink is not under negative pressure in a single direction to the nozzle, but is in an internal circulation state that leads to the nozzle, with pressure, circulation, and can also reduce bubbles. This reduces the problem of white lines caused by bubbles. Simultaneously circulating ink can also provide a constant temperature and cooling effect on the nozzle, thereby ensuring the stable operation of the nozzle.

Schematic diagram of circulating ink supply device and circulating ink supply principle

Schematic diagram of circulating ink supply device and circulating ink supply principle

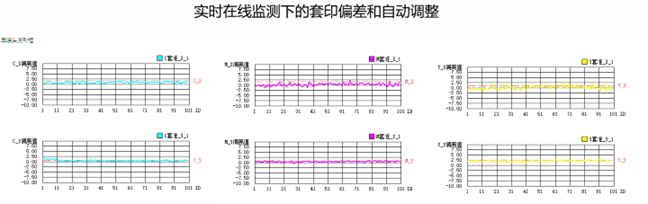

Fangzheng Eagle Eye Online Detection System

Online testing has always been an optional accessory for Japanese and American brands. Taking a Japanese brand as an example, its online testing usually costs over one million yuan. However, in order to improve the stability and convenience of the equipment, Fangzheng has always made online detection a standard configuration for color printing. Many novice users are comparing prices, unaware that experienced inkjet printing companies have long noticed the completeness of their technical indicators and systems. Therefore, many users who are not familiar with technical details request a price reduction for branded equipment at the price of low-end brands, but they do not know that only Fangzheng is equipped with online detection for domestic equipment, and it is a standard configuration.

On the one hand, online detection can use high-speed line array cameras to scan and achieve automatic alignment, and on the other hand, it can also detect and monitor the clogging status of the nozzle in real time, thereby achieving automatic white line filling of the nozzle. Taking P4400CHD as an example, it is necessary to debug the overprint data of 32 nozzles. Without online detection, it may take 10-20 minutes or even half an hour to debug the overprint. But with this online detection system, automatic alignment usually only takes 10-20 seconds, and as printing production progresses, the software system will scan and detect in real time to achieve automatic alignment and deviation control during the printing process, ensuring accurate printing.

From a business perspective, initially blindly entering the POD industry may be limited by the investment threshold of the equipment. However, as they become more aware of the stability and professional requirements of the equipment, they no longer solely consider the equipment price, but increasingly consider the overall performance and comprehensive usage cost of the equipment. Therefore, entering the stage of copperplate paper color inkjet printing, the investment and selection of POD equipment are becoming increasingly rational and mature. After the Beijing Printing Exhibition, the inkjet market for colored copperplate paper suddenly exploded, making brand equipment like Fangzheng increasingly favored and praised by the market. I believe that after experiencing a period of rapid growth and blind investment, the POD market will gradually return to specialization and branding in equipment selection and procurement.