Lemei Packaging launches Phase II in Indonesia and builds the largest single factory in Kunshan, with a dual core strategy to restructure the industry landscape!

Lemei Packaging, a leading supplier of high-quality, environmentally friendly, sterile packaging products and solutions headquartered in Kunshan, Jiangsu, China, has recently launched its second phase investment in its Indonesian factory in Silang County, Bandan Province, Indonesia. This marks significant progress in the first overseas expansion of Lemei Packaging Group and makes the factory the first in Indonesia to provide end-to-end sterile packaging production. The Indonesian Minister of Economic Coordination, Elronga Hatato, officials from various ministries and agencies, local leaders, and representatives of the Packaging Association attended the inauguration ceremony together.

Anton Hui, General Manager of Lemei Packaging Indonesia, introduced that the sterile packaging factory covers an area of 16.2 hectares, with a construction area of over 55000 square meters, equipped with world-class advanced equipment, and is the most advanced factory built by Lemei Packaging so far. After the new production line is put into use, the annual total production capacity of the factory will increase from 12 billion packages to 21 billion packages. The factory began commercial production in 2024 and currently has 450 employees, of which about 40% are from local Banten province. It mainly provides services to the entire food and beverage industry in Indonesia and produces paper straws as supplementary products.

Assist Indonesia's national strategy and target the vast market

Indonesia's Minister of Economic Coordination, Hatato, pointed out that the construction of the second phase of Lemei Packaging's Indonesian factory project will help support President Prabowo Subianto's "Free Meal Plan" (MBG) implemented nationwide. The plan aims to improve the nutritional status of children under five years old, pregnant women, breastfeeding mothers, and students under high school.

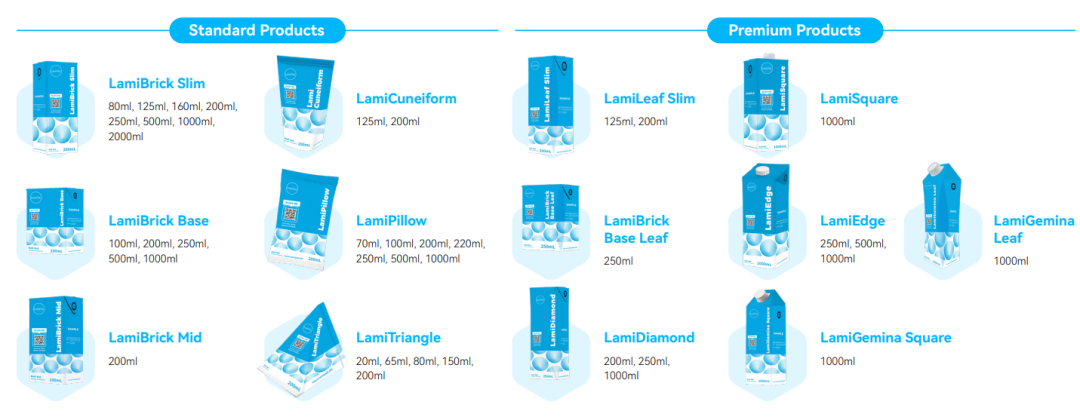

Minister Hatato said after visiting the factory, 'As long as MBG plans to provide beverages, it would certainly be very beneficial.'. "LeMei Packaging provides various roll and sleeve packaging including brick bottom packaging, pillow shaped packaging, and triangular packaging, as well as environmentally friendly innovative technologies such as aluminum free technology Laminure and paper straws, which can reduce carbon emissions by up to 28%. These have formed a good synergistic effect with Indonesia's national plan.

This investment in Indonesia also represents an important step for Lemei Packaging towards the growing food and beverage market in Southeast Asia. This not only highlights Indonesia's increasingly important position as a manufacturing hub in the region, but also reflects the trend of multinational corporations seeking to expand their production facilities closer to major emerging markets. The domestic sterile packaging market in Indonesia is continuously growing, increasing from IDR 87.6 trillion in 2022 to IDR 93.2 trillion in 2023, and is expected to exceed IDR 100 trillion by the end of 2024. With the increasing demand for environmental protection and modern packaging solutions, it is expected that the market will grow by 24% in the next five years, making Southeast Asia one of the fastest-growing regions.

LeMei Packaging: Leading domestically, targeting the global market

LeMei Packaging not only actively expands into overseas markets, but also continues to make efforts domestically. The 2024 sustainability report released by the company shows that as of 2024, its products and services have been distributed in over 80 countries worldwide, with a total sales revenue growth of 25%. The total sales of sterile packaging have reached 16.8 billion units, and the total sales of paper straws have also reached 760 million units.

The factory in Kunshan, China is also developing synchronously: the current production capacity is 18 billion packaging units, and plans to expand to 30 billion packaging units by 2026. The factory has obtained LEED Platinum certification and an automated warehouse will be put into operation in 2024, capable of storing 9080 rolls of products. In addition, the R&D headquarters building of Lemei Packaging was officially put into use in May this year, aiming to create an integrated platform for "industry university research application", further enhancing its R&D strength and international competitiveness in the fields of sterile packaging and new materials.

Looking ahead to the future: Deepening technological innovation and restructuring the industry landscape

In order to further consolidate its industry position, Lemei Packaging Kunshan Factory is actively promoting a series of new projects. The company plans to introduce new material projects such as film coating and bottle caps on the basis of its existing product manufacturing scale, as well as future four phase planning projects, with a total investment of over 3 billion yuan.

The film coating project will adopt advanced aluminum foil removal technology, and can produce 30 billion sterile bags after full production to meet the high demand of international customers for green and recyclable packaging materials. The bottle cap project aims to develop and produce sealed cut film caps for sterile packaging, enriching the product line while providing customers with higher quality products, thereby enhancing market competitiveness.

In addition, the Phase III liquid sterile packaging project, which will increase capital in 2023, is also under intense construction. It is expected to complete equipment installation and conduct trial production by December 2025. After the project is fully operational, the annual production of sterile liquid food packaging materials will reach 30 billion packages, with an annual sales revenue of 5 billion yuan, and it is expected to become the world's largest single unit factory for sterile liquid food packaging production.

The second phase investment of Lemei Packaging in its Indonesian factory is not only an important step in its own globalization strategy, but also a typical example of Chinese manufacturing companies expanding overseas. By establishing advanced factories in Indonesia, Lemei Packaging has achieved localization of production, thereby responding more quickly to local market demand and effectively avoiding potential trade barriers. This move also coincides with the Indonesian government's strong promotion of the "Free Nutrient Meal Plan", providing a huge market opportunity for Lemei Packaging. At the same time, it also demonstrates the determination of Lemei Packaging to continue to deepen its cultivation in the domestic market.

Through the expansion of production at the Kunshan factory, the opening of the R&D headquarters, and the planning of a series of new material projects, Lemei Packaging is actively enhancing its technological strength and innovation capabilities. From adopting advanced aluminum foil coating technology to developing matching sealed bottle caps, it reflects the company's efforts in environmental protection and product diversification.

The strategy of "walking on two legs" - emphasizing both overseas market expansion and deep cultivation of domestic technology - has enabled Lemei Packaging not only to maintain a leading position in the domestic market, but also laid a solid foundation for restructuring the market pattern in the global aseptic packaging industry. It can be said that Lemei Packaging is steadily moving towards the goal of becoming a global leader in the aseptic packaging industry through continuous innovation and investment.