At the 2025 European Label Expo, see the dazzling new changes in digital printing technology

From September 16 to 19, 2025, the 2025 European Label Printing Exhibition was successfully held in Barcelona, Spain. As one of the professional exhibitions in the label industry, this event showcased products covering multiple fields such as printing equipment, printing consumables, and software platforms, providing attendees with an industry feast of new technologies and new materials. The most eye-catching parts were digital printing, flexographic printing (including hybrid printing), and printing materials. In this article, the author will introduce the current innovative technology developments in these three areas based on personal observations and insights.PART.01Digital PrintingAs is well known, digitalization in printing is the future trend for label printing and the entire printing industry, and it is also an essential path for companies to transform. At this exhibition, several well-known digital printing equipment suppliers showcased new equipment characterized by high speed, intelligence, high quality, and multi-process combinations. The application of new technologies has greatly improved printing efficiency, image and text quality, and operational flexibility. Below, the author lists some of the technologies showcased by well-known digital printing brands.01HPAt this exhibition, HP's booth featured the brand-new HP Indigo 6K digital press and HP Indigo V12 digital press. The HP Indigo 6K digital press introduces a Smart control system and intelligent tools, enhancing equipment stability, completing orders quickly, and achieving high-efficiency output. The HP Indigo V12 digital press adopts the newly developed LEPx technology, capable of continuous full-speed production at 120 m/min. Through improvements in its own performance and the quality of electronic ink, the device significantly enhances the quality of printed products.

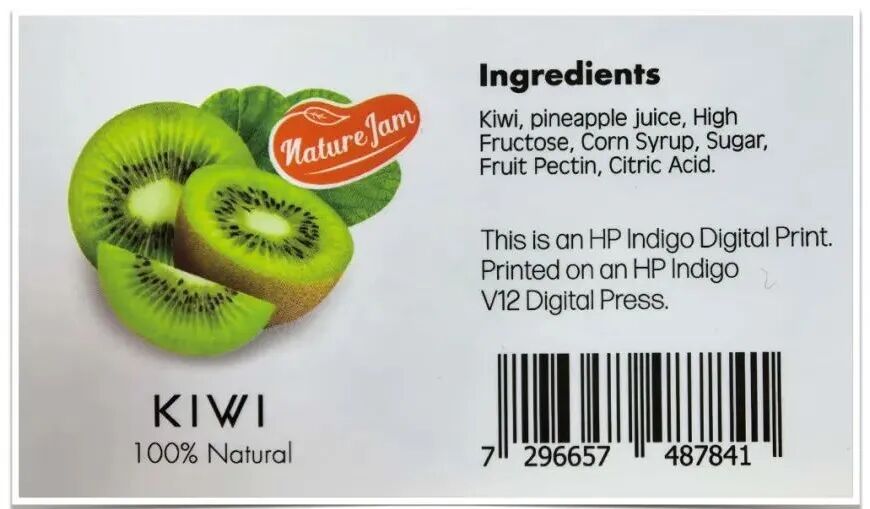

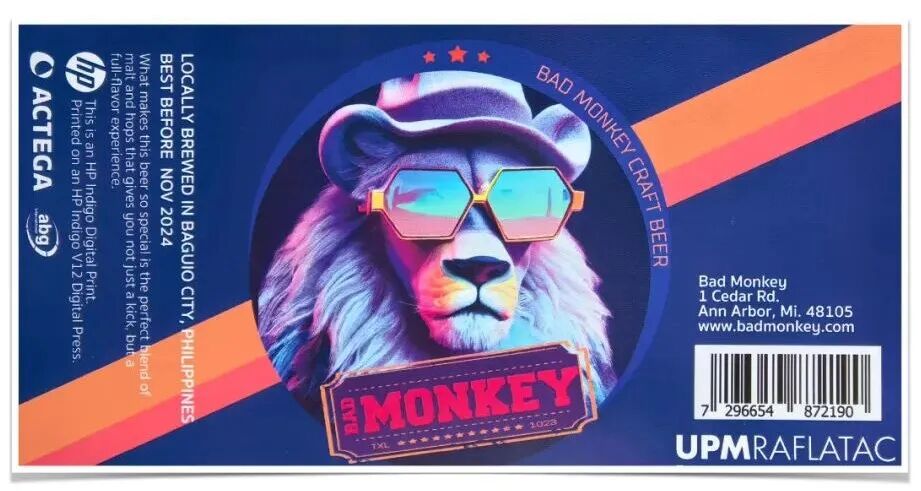

Figure 1

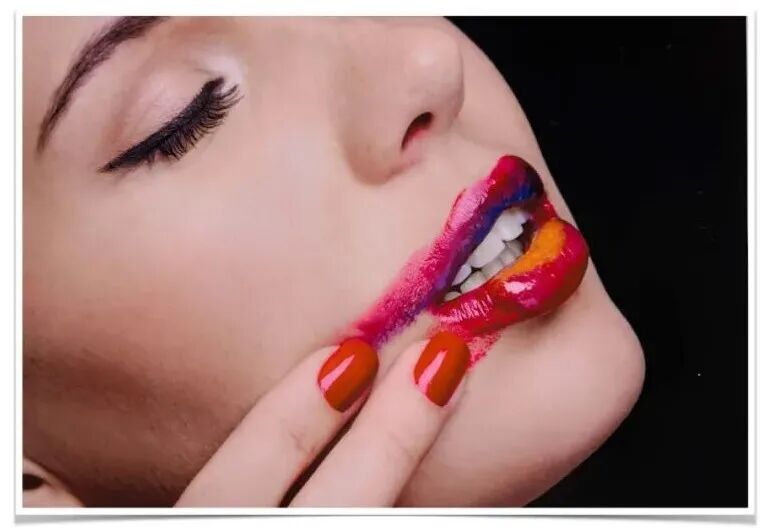

Figure 2Figures 1 and 2 show label samples we obtained from the exhibition site. It can be seen that the printed items have surpassed the ordinary offset printing in terms of dot shape and color saturation, reaching or approaching the level of flexographic printing. Especially at the edges of text or lines, the jagged effect (fringe effect) has basically been eliminated, consistent with the printing effect of standard flexographic printing. It can be said that the printing effect and quality of the HP Indigo V12 digital press have reached the standard of flexographic printing and may perhaps become a future alternative to flexographic printing.02PrimeraAt this exhibition, Primera showcased the Smart series and DPIM series digital presses. Both devices use upgraded industrial-grade printheads, with a maximum resolution of up to 1200×1200 dpi. The printing text and image quality and production efficiency have been greatly improved, meeting customer demands for high efficiency, high quality, and high adaptability.

Figure 3

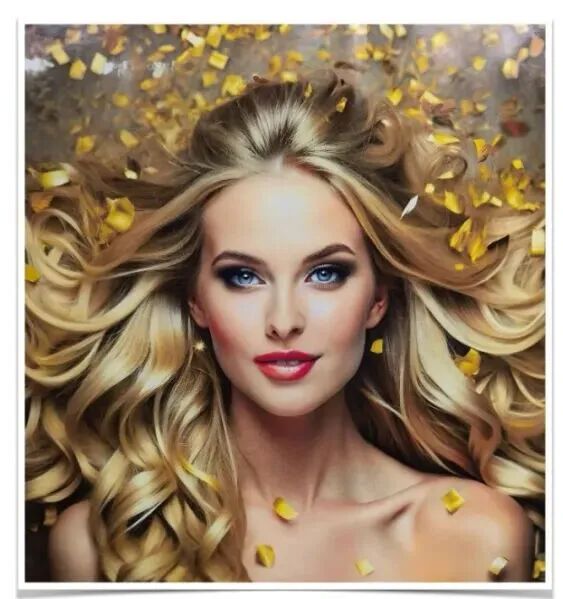

As shown in Figure 3, this is a sample label promoted by Prisco a few years ago. It can be seen that the printed graphics are relatively rough. The discontinuity in tonal gradation can be clearly seen on the faces and bodies of the figures, along with moiré patterns and granularity. This is due to the low resolution of the graphics, frequency modulated screening missing highlights, and moiré breaks. On the other hand, as shown in Figure 4, these are the label samples exhibited by Prisco at this expo. By comparison, due to the improved resolution of inkjet printing, the issues of moiré breaks, discontinuous tonal gradation, and rough surfaces in the highlights of figure graphics that were present before have basically disappeared. In the figure images of the label sample in Figure 4, the skin is excessively even and textured, no moiré or granularity is visible in the highlighted areas of the face, and the hair appears very natural. The printing quality is almost indistinguishable from traditional offset printing; without a magnifying glass, it is impossible to tell which printing method was used.

Figure 4

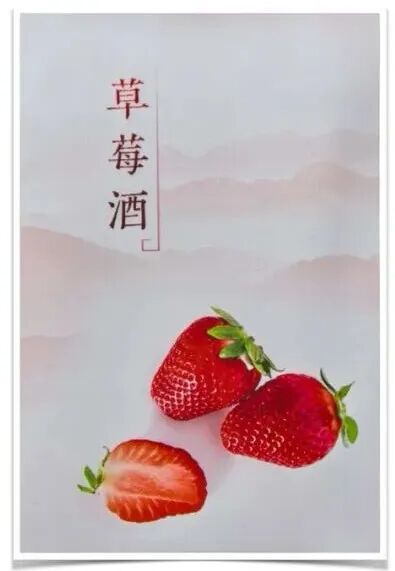

Now take a look at the label sample shown in Figure 5. The entire print has distinct contrast; the dark areas of the fruit have clear dots without merging, with well-defined layers. The highlights in the background mountains and sky are uniformly smooth, with almost no graininess, creating a sharp contrast with the fruit areas. Such an effect is difficult to achieve with traditional printing. It can be said that technological progress has changed the visual impact.

Figure 5

03

TongyinAt the exhibition, Tongyin showcased innovative products such as the Label Modular 330 HD digital-flexo hybrid press and the Falcon mobile label printing platform. Tongyin is one of the leading companies in software applications and color management in China. The Label Modular 330 HD digital-flexo hybrid press, produced in collaboration with Spandex, has been selling very well domestically, with a trend of demand exceeding supply.

Figure 6

The samples obtained from the site can help us understand the technical level of screen printing. Figure 6 shows a tag with a character's portrait. It can be seen that the colors are bright and the layers are rich, without some of the defects that used to occur with inkjet printing. Under a magnifying glass, the small dots in the highlights are uniform, while the darker tones also show distinct layers. The print quality and effect completely surpass offset printing and are similar to flexographic and gravure printing. This is because offset printing uses less ink and is not as vivid, while flexographic and gravure printing use more ink. Inkjet printing can match them because, after adjustment, the ink amount in inkjet printing can be equivalent to screen printing. This is why people are increasingly fond of inkjet printing.

Figure 7

Figure 7

shows a comparison between four-color printing and seven-color printing in a set of sample prints. It is clear that the images and text printed with seven-color printing have significantly better color richness and clarity than traditional four-color printing. Seven-color printing (also known as wide gamut printing) is a new technology currently being actively promoted by printing schools, software companies, and equipment suppliers in China. This technology has been developed for many years in developed countries and has certain requirements for the entire supply chain, such as equipment configuration, ink, and material stability. Promoting seven-color printing using digital printing is relatively simpler because digital printing does not require equipment to be precisely adjusted and fixed like offset or flexographic presses. With the stability of materials and inks ensured, digital printing can rely on software and related programs to adjust the equipment. Therefore, digital printing has an inherent advantage in promoting seven-color printing, and it is hoped that Tongyin will achieve greater success in this area.04DeshiAt the exhibition, Deshi showcased the KJET hybrid printing machine, which supports printing speeds of up to 100 m/min, and the N730i label digital printer with a resolution of 1200x1200 dpi. Simultaneously, they also launched the new G3 printing equipment, equipped with the Durst Hawk AI™ system, which corrects printing errors in real time, reducing waste and improving production efficiency.

Figure 8

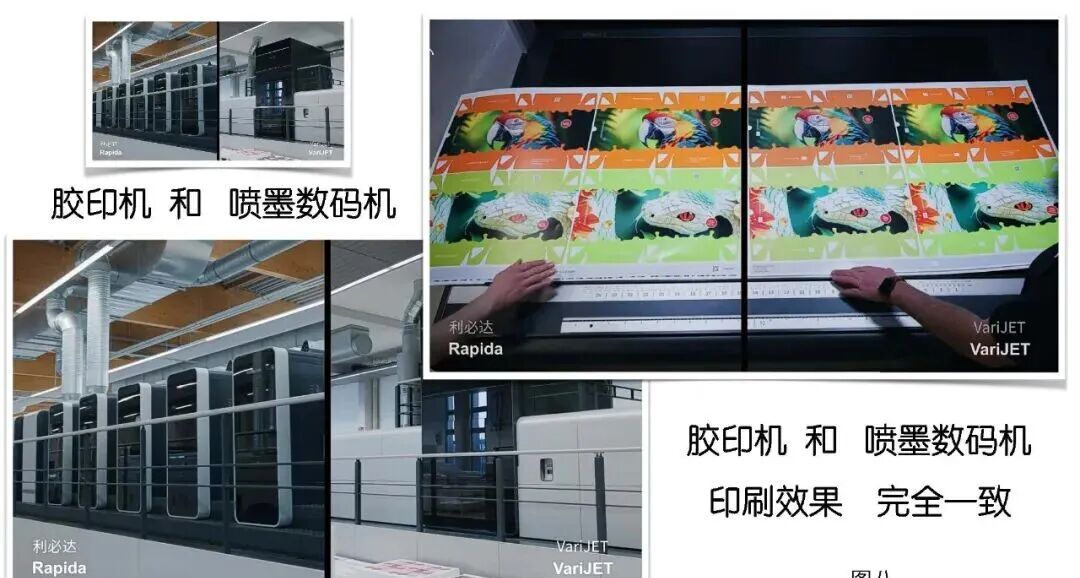

Figure 8

In recent years, many companies that manufacture flexographic and offset printing presses have been cooperating with Dedi to produce hybrid label printing presses or packaging printing equipment. These hybrid printing machines are internationally top-notch in terms of equipment configuration and print quality. Figure 8 shows a comparison between prints from VariJET digital printing and Rapida offset presses. It can be seen that after color management, the printing results of the two are completely consistent, and it is difficult to distinguish the printing method of each print without a magnifying glass. This demonstrates that digital printing can fully replace some traditional printing methods, and can even achieve better results. The era of digital printing has truly arrived.

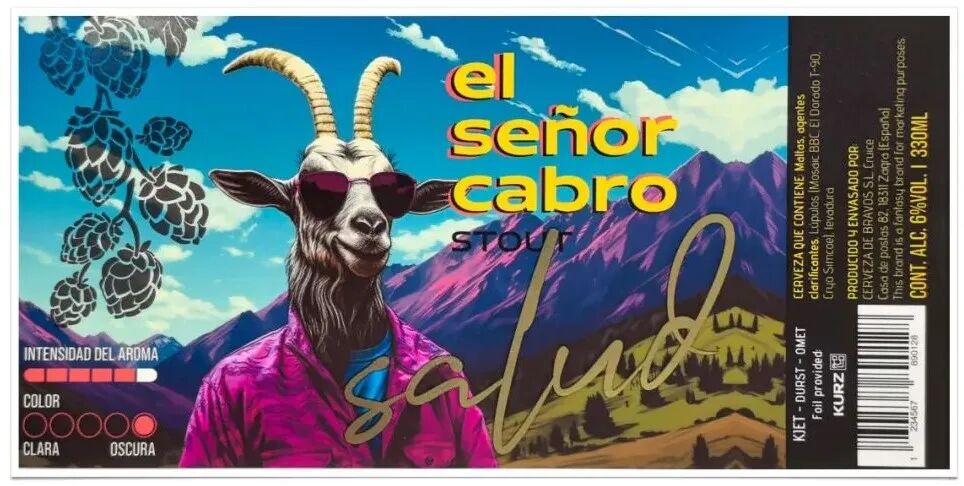

Figure 9

shows a wide-color-gamut (seven-color) label printed by the Ohmeet KJET hybrid press. The label displays vibrant colors, rich layers, accurate registration, and lacks the common issues in traditional printing such as loss of highlights in small dots, enlargement or merging of large dots. The transitions between different dot layers are smooth. Flexographic cold foil and spot varnishing enhance the label's three-dimensionality and visual impact. The entire label is primarily digitally printed, with flexography adding finishing touches. Together, they achieve the best shelf appeal.05SAICANAt the exhibition, SAICAN showcased the Xeikon PX3000HD digital press, which uses the independently developed PX-Cure LED HD inks, offering a maximum resolution of 1200×1200 dpi. SAICAN's equipment is a digital printer that uses toner based on electrostatic principles. Toner printing technology, due to its raster screening method similar to traditional printing, is also amplitude modulated, making it widely adopted.In recent years, with improvements in toner quality, higher resolutions, and reduced toner dot scattering, there have been significant enhancements in dot color saturation and deformation, making the print quality closer to traditional printing. Consequently, its market share has increased year by year. According to this year's European label exhibition, SAICAN has sold several thousand units globally and has also achieved good sales results in the Chinese market. It is hoped that SAICAN will continue to improve its technological level, providing consumers with more options and promoting the digital printing market.06RuntianzhiAt the exhibition, Runtianzhi displayed the Caishen FLORA series ORCA 350 digital press, featuring an integrated design of "digital printing, flexography, varnishing, and hot stamping," suitable for various applications from traditional labels to flexible packaging.Runtianzhi's largest market is outdoor advertising. It has not been in the label printing industry for long, but due to relatively stable equipment quality, fast product iteration, and good after-sales service, its market share in the industry is still considerable. It is currently one of the main suppliers of digital printing equipment in China's label printing industry.