What should I do if there is a "ghost shadow" during flexographic printing? Share a few feasible measures

In the past few years, APR has shared many articles analyzing the causes of flexographic printing problems and providing improvement methods, such as dirty printing, ink smudging, and ghosting. With the continuous development of technology and equipment, as well as the continuous improvement of the operational level of practitioners, we have found it necessary to re-examine these issues that still plague many printing companies today.

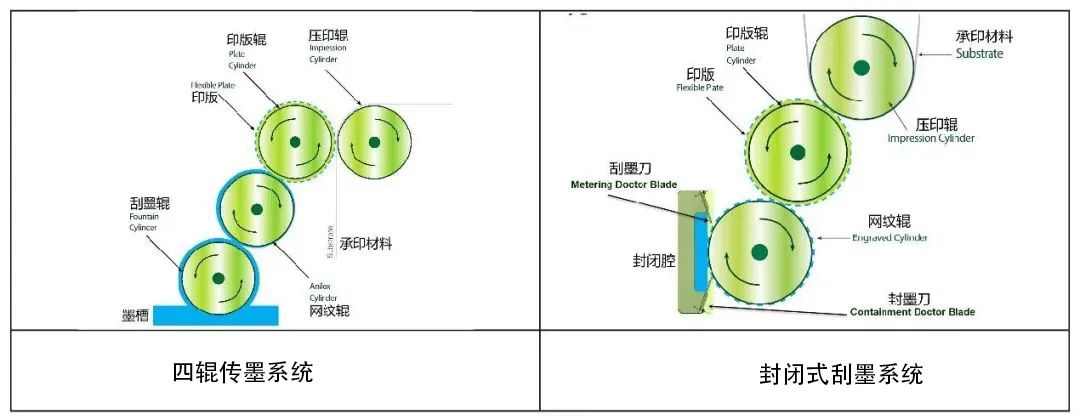

When recalling my experience of just starting to solve various flexographic printing problems, I often recall the exact time and place when I first encountered a specific problem. In 1982, when I received training as a newly hired printing operator, my understanding of the flexographic ink system was only one - the four roll ink supply system. At that time, the printing press had a rubber scraper roller immersed in an ink tray to transfer ink to the web roller. In those years, there was never a mention in my memory of insufficient ink supply from the printing plate to the printing material. Of course, even if there were, I had no concept of the density of the ground and the term 'ghosting' in flexographic printing.

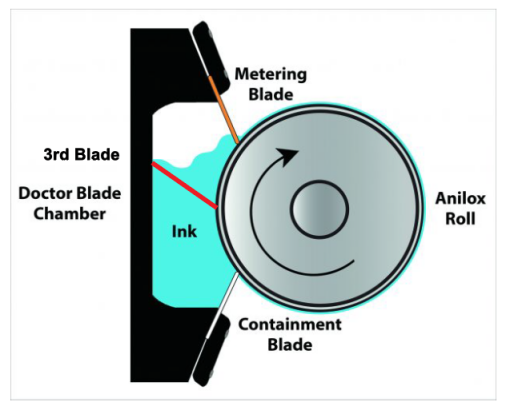

In the 1980s, flexographic printing machines began using a new component, now commonly known as a closed ink scraping system. This component plays a very important role in improving printing quality, increasing printing speed, and reducing ink consumption, and I first discovered the phenomenon of "ghosting" with this new component. In this article, I will introduce how "ghosting" is generated and how to eliminate or reduce it.

01What is' Ghost Shadow '

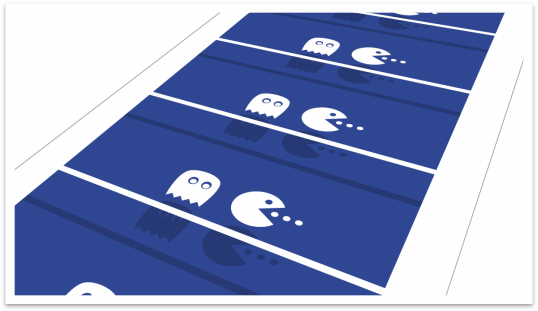

The term 'ghosting' is borrowed from offset printing, and in the field of flexographic printing, it refers to the printing defect of 'mechanical pinhole'. However, in reality, most people tend to agree with another theory, that is, "ghosting" refers to the repeated appearance of dim patterns in other parts of the printed material in inappropriate locations. This type of "ghosting" usually appears in the printing pattern area of the substrate, especially in large areas of solid printing. The incidence of "ghosting" phenomenon has become increasingly common after the emergence of closed ink scraping systems.

02The reason for the 'ghost shadow'

In most cases, the appearance of "ghosting" is often due to insufficient ink filling in the mesh holes of the mesh roller to provide stable color density for the printed material. The "ghosting" problem may not only occur when printing dark colors, but it is indeed more likely to occur when printing dark colors such as brown, red, blue, and green. The fundamental issue in eliminating or improving the phenomenon of "ghosting" is how to improve the ability of the mesh roller to refill and transfer ink from the mesh holes.

03

How to eliminate 'ghosting'

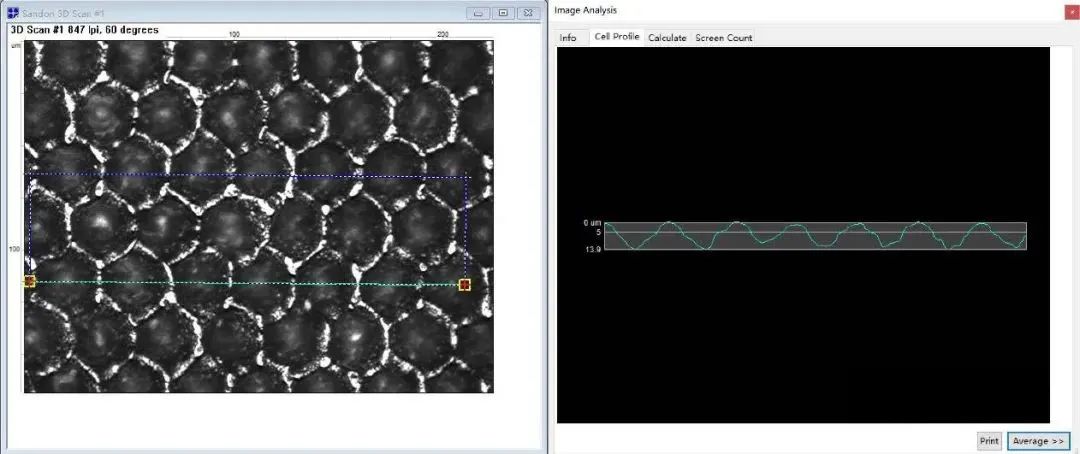

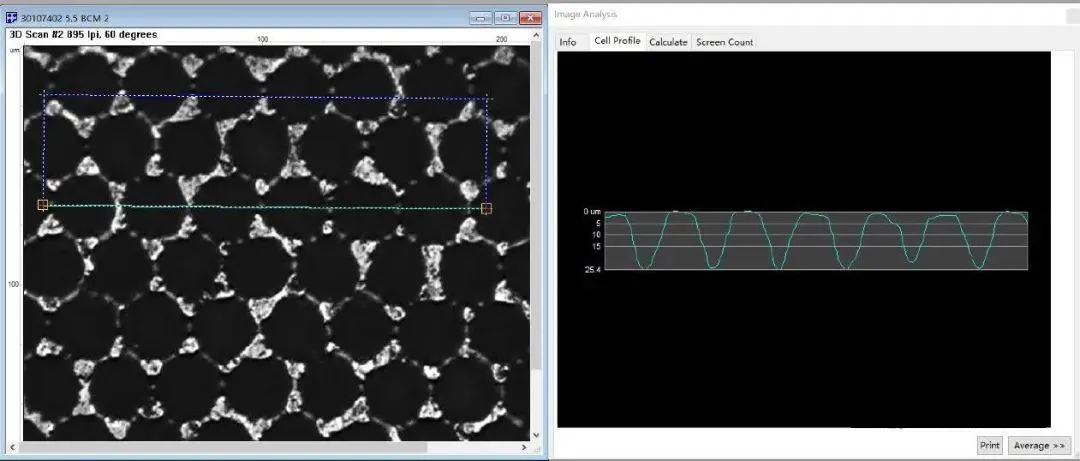

The porosity and mesh depth of the mesh roller mesh wall greatly affect the transfer ability of ink to the substrate. When the printing speed increases, it becomes extremely challenging to stably and effectively refill the ink in the mesh to provide a uniform ink layer thickness to the printing plate. The depth to opening ratio of the mesh is crucial. A deeper mesh usually means a higher ink loading capacity. However, if the surface tension of the printing plate is too low to remove the ink particles inside the mesh, poor ink transfer may lead to the occurrence of "ghosting" phenomenon. Similarly, if the surface tension of the mesh roller is too high, the mesh roller may be able to easily fill ink from the ink roller or ink chamber, but it may not be able to transfer ink to the printing plate properly, resulting in the occurrence of "ghosting" phenomenon.

In addition, due to the topological structure of the surface of the mesh roller, it is almost impossible to accurately measure its surface energy or dyne value. However, it is possible to test the transfer rate of printing plates within a wide range of dyne values. In addition, whether you use solvent ink, UV ink, or water-based ink, appropriate ink viscosity is also very important for improving the phenomenon of ghosting.

深度正常的网孔

Deeply carved mesh holes

04

Feasible measures to minimize the phenomenon of ghosting

To reduce the possibility of "ghosting" phenomenon, the following methods can be tried:

(1) In the color group where the "ghosting" phenomenon occurs, replace the mesh roller with the same ink load but lower line count. In this way, the mesh roller can provide the same amount of ink to the printing plate while reducing the proportion of ink drying on the surface of the mesh roller, as long as the ink transfer rate is similar.

(2) For solvent inks and water-based inks under specific conditions, the reason may be that the ink viscosity is too low. Increasing viscosity can reduce the drying speed of the ink on the surface of the mesh roller.

(3) Due to this printing defect being more common in large areas of solid or windowed areas, there may be white overprinting (on transparent printing materials). In this case, the white ink will dissolve and appear as a "ghost shadow" color. Therefore, increasing the drying speed of white ink may have a good effect.

(4) If possible, place the colors with "ghosting" on the back color group and use ink filled ink chambers to improve the backfilling performance of the mesh.

(5) Ensure that the mesh roller is not blown by the surrounding air, especially the dry hot air flow between colors.

(6) Reduce scraper pressure, which means reducing friction and heat accumulation at the ink cutting point.

(7) Some closed ink scraping systems use fluid dynamics principles to fill each mesh with ink using equidistant inner cavity contours, bringing air back to the ink tank from unfilled mesh holes and releasing it into the atmosphere. This process helps to avoid the "ghosting" and ink shortage caused by the accumulation of air pockets and bubbles in the ink.

(8) Whenever possible, try to extend the dwell time of the mesh roller between the two scraper blades in the ink chamber, or place the problematic color in the color group with a larger closed scraper opening for printing. This can improve the ink filling effect of the mesh of the mesh roller. A deeper ink chamber can reduce turbulence inside the chamber and minimize the cavitation phenomenon that may cause ghosting and ink shortage. A similar phenomenon can be thought of here: among the Five Great Lakes, Lake Erie is the shallowest and most turbulent lake, while Lake Superior is the deepest and calmest lake.

(9) Sometimes adding diluents to ink can also improve severe ghosting, or using a mixture of 10% n-propyl acetate and 90% ethanol.

(10) Although it cannot be used as a conventional method in production environments, reducing the speed of printing machines can indeed reduce the incidence of ghosting.

(11) Although not very practical, another solution is to use special mesh rollers to deal with orders with more serious "ghosting" problems. If the circumference of the mesh roller is the same as or a multiple of the printing circumference, then the mesh roller will synchronize with the printing pattern and the "ghosting" phenomenon will not occur.

In addition to the above reasons, it is also easy to produce "ghosting" when the final color group is fully printed with varnish, especially when the printing material is paper. The "ghosting" phenomenon is often confused with the back sticking phenomenon (the reason for the back sticking phenomenon is that after the back of the printing material comes into contact with the printed pattern, the ink is transferred from the printed pattern to the back of the printing material). Usually, due to excessive pressure, the varnish roller will pick up the pattern from the substrate and replicate it. Unlike the real phenomenon of ghosting, this situation may occur in both the graphic and non graphic areas of the printing surface of the substrate.

(Original author of the article: Tim Reece, APR Technology Services Group, USA)

translator's note

In recent years, some flexographic printing equipment manufacturers have pioneered the introduction of a closed ink chamber three scraper solution, attempting to solve the stubborn "ghosting" problem in flexographic printing technology that cannot be improved by other conventional means, and have achieved relatively positive results in some production process scenarios and practices. However, due to various subjective and objective reasons, this solution has not been widely promoted and applied in the industry.