What is the innovation of this process in solving the technical problem of "hot stamping before printing"?

With the continuous improvement of production efficiency, cost, and printing quality requirements in the packaging printing industry, the limitations of products using the traditional "hot stamping first and then printing" process have become increasingly prominent as their volume continues to grow. Due to the use of hot stamping holographic aluminum before printing, there are problems such as low production efficiency, insufficient registration accuracy, large material loss, and complex processes. In response to the above issues, this article proposes a holographic positioning roll paper gravure printing technology, which adopts a continuous production method of roll paper, combined with holographic film pressing, registration cursor recognition, and dynamic tension control, to achieve high-precision and high-efficiency printing. This technology can be widely applied in fields such as cigarette packs, wine boxes, and high-end cosmetic packaging, and has important industrial application prospects.

Holographic positioning roll paper combination printing process

The holographic positioning roll paper combination gravure printing technology proposed in this study mainly includes three steps: firstly, the roll paper is pressed into a positioning paper through a holographic film press, and laser graphics and registration cursor are pre-set on the paper surface; Secondly, roll up the laminated roll paper and place it into the roll paper printing machine; Finally, register printing of printed graphics and text is achieved through the use of registered light identification reading. Compared to traditional flat paper technology, this method has significant advantages. It uses roll paper as the printing carrier and is adapted to use roll paper printing machines, greatly improving the processing speed of paper products; By replacing the previous pre gauge and side gauge alignment methods with cursor alignment, the accuracy and quality of the product have been significantly improved.

Roll positioning paper is a key link in combination printing, and its process includes multiple fine steps: firstly, laser engraving technology is used to produce a positioning anti-counterfeiting metal master plate, which serves as the standard template for film preparation. Then, using PET film as the substrate, the bottom layer is coated using a coating machine. Then press the holographic positioning laser transfer film on the holographic film press, and print the laser graphics and registration cursor required for the printed product on the film. Subsequently, the PET optical film substrate imprinted with holographic positioning laser transfer film was placed into a high vacuum aluminum plating machine for surface vacuum aluminum plating. Finally, the PET film substrate that has been vacuum coated with aluminum is subjected to composite peeling on the laminating machine, and a protective layer or color developing layer is coated on the surface, followed by humidification treatment to produce positioning laser paper. This series of processes ensures high-precision production of graphics, text, and alignment cursor.

Holographic positioning roll paper combination printing

Analysis of Technical Difficulties

The holographic positioning roll paper gravure printing technology mainly faces technical challenges in film making, paper film composite, and printing registration in practical applications.

01/Difficulties in controlling the film making process

(1) Substrate stretching deformation: The stretching rate of BOPP/PET film is inconsistent between batches, and further deformation is caused by temperature and tension during coating and molding, resulting in unstable holographic pattern size.

(2) Hot deformation during compression molding: High temperature compression molding (120-180 ℃) can easily stretch the film material, causing changes in the spacing between holographic patterns and affecting subsequent process alignment.

(3) Accumulation of aluminum plating errors: Fluctuations in tension during the aluminum plating process result in increased positioning deviation of holographic patterns.

02/Control difficulties in the composite process of holographic positioning roll paper film

(1) Tension matching problem: The tension mismatch between the film and paper can easily lead to wrinkles or tensile deformation of the composite material.

(2) The influence of paper moisture: Changes in temperature and humidity cause paper to stretch and deform, resulting in a displacement of holographic patterns.

(3) Sticky pattern defect: Uneven composite may lead to a decrease in holographic pattern brightness or surface defects, increasing the scrap rate.

03/Control difficulties in holographic positioning roll paper printing process

(1) Paper thermal deformation: During the printing and drying process, the paper expands and contracts due to heat, making it more difficult to register accurately.

(2) Holographic and printed graphic matching: It is necessary to ensure that the intaglio graphic completely overlaps with the prefabricated holographic pattern, and the error should be controlled within ± 0.1mm.

Holographic positioning roll paper combination printing

application solution

In response to the multiple technological challenges in film making, lamination, and printing processes, this study proposes the following innovative solutions through in-depth research and innovative optimization of key processes.

01/Optimization design of alignment cursor

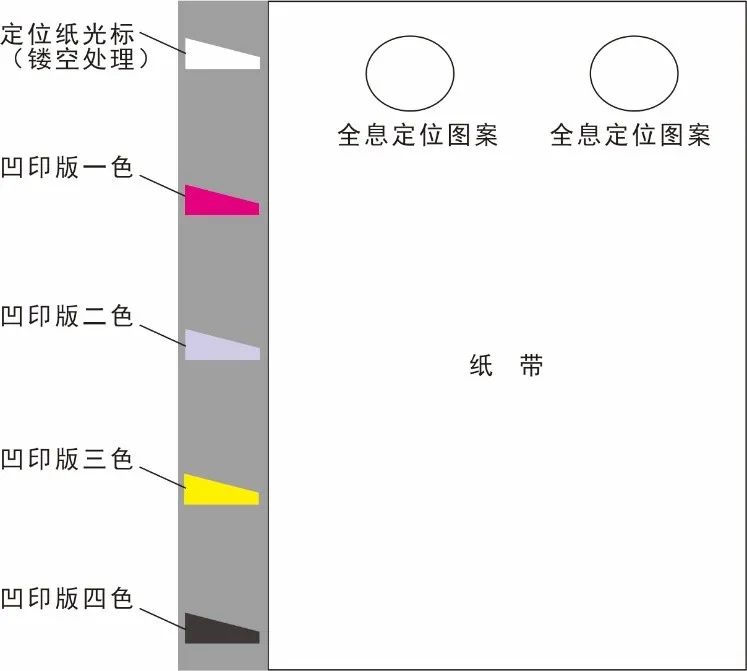

In order to improve the accuracy of registration, the holographic positioning web cursor was optimized according to the requirements of gravure printing machine registration and the principle of photoelectric head recognition. The traditional solid shaped registration cursor is produced through hot stamping, and its cursor surface is less easily recognized by the electric eye compared to the surface produced by ink printing. To solve this problem, this method uses a nested cursor with a hollow structure on one side of the paper tape, as shown in Figure 1. In the test, the printing accuracy and stability between the various color groups of the gravure printing were good, with a printing accuracy deviation of ≤± 0.1mm. Therefore, this design enables the gravure printing machine's electric eye to perform registration work against the hollowed out cursor, significantly improving the stability and accuracy of the printing.

Figure 1: Set a hollow structure registration cursor on one side of the paper tape

02/Improvement and Optimization of Web Printing Machine

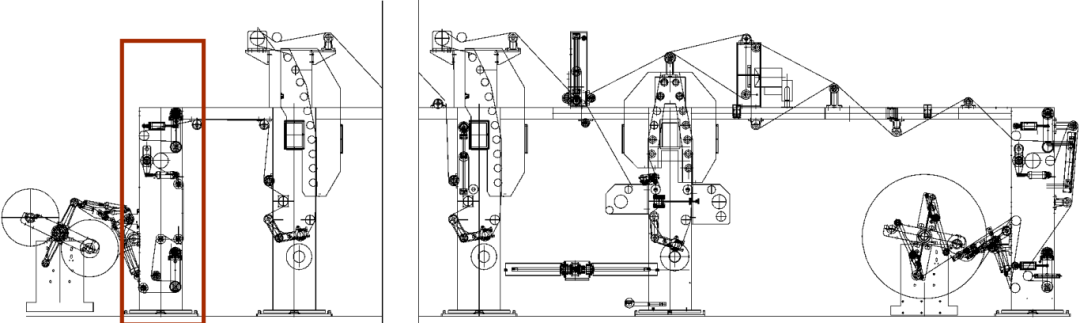

(1) Add a fixed length stretching (pre alignment) device to the unwinding unit of the printing machine, as shown in Figure 2. To meet the process requirements of pressing the film first and then printing, this study has made multiple improvements and optimizations to the roll paper printing machine. Firstly, a fixed length stretching (pre alignment) device has been added to the unwinding unit of the printing machine to adjust the amount of expansion and contraction deformation of the roll paper caused by film pressing. The device includes a traction roller, an electric eye, a compensation roller, and a paper guide roller driven by an independent servo motor, which can adjust the paper tension in real time according to the registration cursor information to ensure printing accuracy.

Figure 2: Adding a fixed length stretching (pre alignment) device to the unwinding unit of the printing machine

Figure 2: Adding a fixed length stretching (pre alignment) device to the unwinding unit of the printing machine

(2) Determine key parameters through experiments: the circumference of the roll paper film press plate should be the theoretical value multiplied by the deformation constant (0.9399~0.9699); The circumference of the first color plate roller of the roll paper gravure printing machine is the theoretical value multiplied by (1+deformation constant), and the deformation constant is preferably 1.0 ‰ to 1.5 ‰; The circumference of the roll paper die cutting roller is the theoretical value multiplied by the deformation constant, preferably between 1 ‰ and 4 ‰.

The roll paper that has been laser positioned and pressed is installed in the unwinding unit of the roll paper gravure printing machine. The roll paper is pulled into the first group of printing units by the gravure printing machine. The dual electric eyes located at the output of the first group of printing units simultaneously collect information from the holographic positioning cursor and the printing registration cursor. The collected data is compared by the computer to analyze the position information of the printed graphics and text. If there is a position deviation, the computer controls the rolling motor of the first group of printing units to change the speed to compensate for the error. When the position reaches the preset position, graphic and text printing is carried out. These optimization measures effectively solve the problem of excessive distance error between holographic graphics and printed graphics during the printing process.

This study has successfully overcome the core challenges of holographic positioning roll paper gravure printing technology through systematic process optimization and technological innovation, significantly reducing the consumables and labor costs caused by the flat ironing and offset printing processes, and providing an efficient, accurate, and reliable solution for the packaging printing industry. With the continuous improvement of processes and the iterative upgrading of equipment, this technology is expected to achieve large-scale applications in more high-end packaging fields, promoting the industry to move towards intelligence and green direction.