What are the special features of the screen printing and gluing process for cigarette packaging gift boxes? Here is the secret to low cost and high efficiency!

The production of cigarette pack gift boxes requires not only the printing process inside and outside the box, but also the final step of gluing and assembling. The traditional manual glue brushing method has many drawbacks, such as differences in individual operation methods, difficulty in achieving uniform quality standards, and low production efficiency. If the glue on the cigarette pack gift box is not evenly applied, it is easy to cause glue peeling or overflow, contamination and adhesion of the product appearance.

Screen printing is known as "universal printing" in the printing industry due to its thick ink layer, bright colors, wide range of substrate types, and various special ink effects, which can involve multiple industries such as packaging, electronics, clothing, ceramics, etc. Applying screen printing to the gluing process of gift box assembly is a good choice. Its cost is low, the adhesive layer thickness is moderate, stable, and easy to adjust. It can be applied to water-based latex and is environmentally friendly without worrying about exceeding VOCs standards. The adhesive parts can be adjusted and changed freely through film files, with one person applying adhesive and multiple people assembling, saving a lot of labor costs.

Due to the use of adhesive in the screen printing of gift boxes, the printing inside the screen is not ordinary ink but adhesive. Therefore, we have our own set of production processes in terms of equipment, plate making methods, adhesive selection, and document production. Here, we will compare and summarize the differences between traditional ink printing processes.

Equipment selection

Equipment selection

There are many types of screen printing equipment, and traditional screen printing machines are divided into flat press screen printing machines, flat press circular screen printing machines, and circular press circular screen printing machines based on the way pressure is applied. Most paper packaging printing products have a weight range of 80~230g/m2, and fully automatic screen printing machines that use flat press circular printing for surface stickers, inner stickers, sulfuric acid paper, etc. in the early stage of cigarette packaging gift boxes are fully capable of handling them.

However, from the post production process to the assembly stage of the cigarette pack gift box, it is usually made of hard cardboard that has already undergone lamination technology. Its thickness is large, its stiffness is high, and it is not suitable for bending. It is not suitable for flat pressing circular printing, so it is more suitable to use a compact flat press screen printing machine with a large three-dimensional printing space for the gluing process, as shown in Figure 1. A larger three-dimensional space can accommodate multiple layers of cardboard with different thickness specifications, directly utilizing the stiffness of the cardboard as a printing platform to improve production efficiency.

Figure 1 Flattening Screen Printing Machine

The production of screen printing

The production process of screen printing can be roughly divided into: stretching the screen, applying photosensitive adhesive, drying, exposure, developing the plate, and inspecting the plate. Ink printing and adhesive printing have significant differences in the selection of plate materials and processes, as shown in Table 1.

Table 1 Differences between Ink Printing and Adhesive Printing

Water based latex uses water as a diluent, and its solubility on the screen is not as good as ink. When choosing the mesh size, it is advisable to use a mesh size of around 200-250 mesh, which can effectively balance the thickness of the adhesive layer and avoid frequent clogging. For the printing of ink products, in order to ensure the precision of printing graphics and text, it is often necessary to use mesh with a mesh size of 300-450 or higher to make the plate.

01/Type of photosensitive adhesive

The selection of photosensitive adhesive is also one of the key points. Manufacturers produce different types of water-resistant diazo photosensitive adhesive and oil resistant diazo photosensitive adhesive according to different situations. If oil-based diazo photosensitive adhesive is mistakenly selected for plate making with water-based latex, it can cause problems such as delamination and poor printing resistance of the plate.

02/Exposure

Stick the film substrate onto the P surface of the screen and expose it to ultraviolet light. The part exposed to ultraviolet light loses its water solubility. Depending on the type of photosensitive adhesive and exposure time, refer to the exposure schedule on each page of the manual and determine the optimal exposure time before exposure. Insufficient exposure can reduce the screen's durability, while excessive exposure can affect the clarity of the image.

03/Plate development

Soak both sides of the exposed screen in clean water or place it in a sink for 1-2 minutes. After removal, rinse the screen with a high-pressure water gun in the form of water mist (the parts exposed to ultraviolet light have photosensitive glue hardened on the screen, and the parts not exposed to ultraviolet light dissolve in water) until all graphics and text are developed clearly. Remove excess water and dry at a temperature below 40 ℃.

04/ Inspection version

Dry inspection, correct the screen, and repair the pinholes.

The use of dura mater agents

Ink printing requires the screen to have good solvent resistance and flexibility of the mesh, excellent printing adaptability, and excellent screen stripping and regeneration properties. Therefore, it is not suitable for the use of dura mater. On the other hand, the adhesive on gift boxes causes more severe wear on the printing plate due to the thick and hard cardboard, as well as the large printing mesh distance. In addition, water-based latex corrodes the photosensitive film of the printing plate. The screen printing durability is often less than 5000 prints, which can lead to adhesive peeling. Therefore, in order to further improve the printing plate durability and enhance the water resistance of the photosensitive adhesive film, it is necessary to use a hard film agent.

The screen printed hard film agent is a two-component set of two bottles. After mixing, apply it to the surface of the screen made of water-based or water-based double-sided photosensitive adhesive, which can effectively protect the photosensitive film of the screen, improve the printing resistance of the screen, and extend the service life of the screen.

The usage method is as follows:

(1) Mix solution A and solution B in a 1:1 ratio and shake well.

(2) After developing the screen, dry it and use a lint free cloth or sponge dipped in AB mixture to apply it to the surface of the screen. Apply it on both sides, not too much. Do not let the liquid pile up on the screen to prevent clogging of the screen holes after solidification.

(3) After drying, the screen can be transferred to the printing process

By using a hard film agent, the screen printing durability can reach around 20000 prints, with significant improvement and enhancement.

Selection of Adhesive

UV pressure-sensitive adhesive and water-based latex that can be screen printed have the following different characteristics: UV cured pressure-sensitive adhesive does not contain water or organic solvents, so it can be cured without going through a heating oven, while water-based latex uses water as a diluent, which can be quickly dried by heating, or can evaporate and naturally dry at room temperature.

UV curable pressure-sensitive adhesives use acrylic monomers as diluents, which have better water resistance and lower surface tension. Therefore, UV curable pressure-sensitive adhesives are more suitable for screen printing on low surface energy surfaces, such as surfaces coated with printing ink; However, water-based latex often reduces its water resistance due to the presence of hydrophilic additives such as emulsifiers. Therefore, the printing plate needs to be treated with a hard coat to enhance its water resistance. Water based latex is widely recognized by customers for its long application experience, while UV curable pressure-sensitive adhesives, as an emerging technology, will play an increasingly important role in future applications. However, considering the overall cost and environmental protection, it is currently more cost-effective to use water-based latex.

Choose the appropriate rubber scraper

Rubber scraper has four functions, which can make ink flow through the screen; Can make the screen in contact with the printing material; Can ensure that the screen is compatible with the printing and material surface; Can remove excess ink from the screen.

The hardness of the rubber scraper is usually expressed in Shore hardness, which ranges from 55 to 95 Shore degrees. Ink products require the precision of printed images, usually using a rubber scraper with moderate or high hardness, which completes a reciprocating motion of ink return after a single scraping process. Glue application does not require high precision for graphics and text. Choose a softer scraper that is more compatible with the surface of the screen and requires less printing pressure. The two scrapers can be alternated back and forth to complete two printing processes.

Accurately control the amount of glue applied by utilizing the characteristics of plate making files

Screen printing adhesive can be precisely controlled and adjusted by modifying the size and density of the dots using a solid substrate.

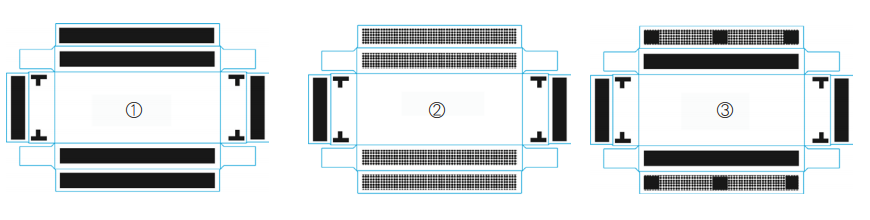

Share a practical case of a company's production of a "Guiyan (Fuzhong Zhi)" inner box, as shown in Figure 2. The first step is to use the fully solid bottom of the box, as shown in Figure 3, as the adhesive file. During the production process, it was found that after the box was formed, the amount of glue applied was too large, and the glue marks and imprints spread across the back of the box, forming dark marks on the front, which had a significant impact on the appearance quality.

Figure 2 "Guiyan (Fuzhong Zhi)" cigarette pack filter inner box

Figure 3 Schematic diagram of file improvement process

By modifying the file, ② the original text filled in the main body was replaced with circular dots with a diameter of 1.2, reducing the amount of ink on the adhesive layer and solving the problem of dark printing. But after the finished product is boxed, there are some instances of glue peeling. The investigation found that during the printing process, some dots have uneven glue application due to plate blockage. When the plate blockage is severe, insufficient glue application may occur, causing the box to open.

Revise the document again, using a combination of solid and network points, and focus on strengthening some bonding points. The problems of glue opening and dark printing have been thoroughly resolved, and finally form the ③ document and finalize it for mass production.