How many steps did you do correctly in the "three-step" longevity secret of the mesh roller?

Mesh roller, also known as wire roller or ink roller, is used to control the quantitative output of ink or coating amount. As the core of flexographic printing, the mesh roller plays an indispensable role in the production process, and its maintenance and upkeep management are also quite important. In this article, based on years of work experience, the author elaborates on some key points of maintenance and upkeep management for mesh rollers, hoping to bring readers some insights.

Generally speaking, in order to manage the mesh roller well, it is necessary to clean, inspect, install, and store the mesh roller properly.

01

Mesh roller cleaning

If the mesh roller is not cleaned in a timely manner or not thoroughly cleaned after use, it will cause blockage in the next use. Blocking will result in a decrease in the ink volume of the mesh roller, causing color changes, making it difficult to trace samples, and causing huge waste to the enterprise. Therefore, the cleaning of the mesh roller should follow the principle of "cleaning immediately after use", which is the key to ensuring that the mesh roller remains in good condition.

At present, common cleaning methods include particle blasting, manual cleaning with effective and safe cleaning agents, laser cleaning, and ultrasonic cleaning, as shown in the figure. Each cleaning method has its advantages and disadvantages, and how to choose depends on the printing company's own situation.

Common cleaning methods for mesh rollers

Common cleaning methods for mesh rollers

Usually, the cleaning of mesh rollers is divided into three stages: daily cleaning, regular cleaning, and deep cleaning. Generally speaking, daily cleaning refers to replacing the mesh rollers immediately after stopping printing work or during the process of changing orders. Used mesh rollers need to be cleaned immediately; Regular cleaning, which means a more powerful cleaning of the mesh roller that has been working for 2-4 weeks; Deep cleaning refers to the deep cleaning of mesh rollers that have been working for 4 to 8 weeks or more. This cleaning requires strict adherence to the cleaning process on the mesh roller cleaning equipment.

During the cleaning process, it is advisable to use cleaning agents with a pH value within the range of 8-10, and avoid using highly corrosive cleaning agents as much as possible; The temperature of the equipment cleaning agent should be controlled between 35 ℃ and 45 ℃; The concentration of cleaning agent should not be too high. It is recommended to mix 1 part of cleaning agent with 4-10 parts of water; After cleaning, rinse with clean water and blow dry with an air gun; When there are special stains, they should be cleaned immediately.

At present, most printing companies have a very deep understanding of the concept of cleaning mesh rollers, but it is difficult to achieve thorough cleaning. Many times, customers pay great attention to the cleaning of the mesh roller. When they arrive at the site, they find that it has indeed been cleaned, but they have not thoroughly cleaned it, only the surface has been cleaned very clean.

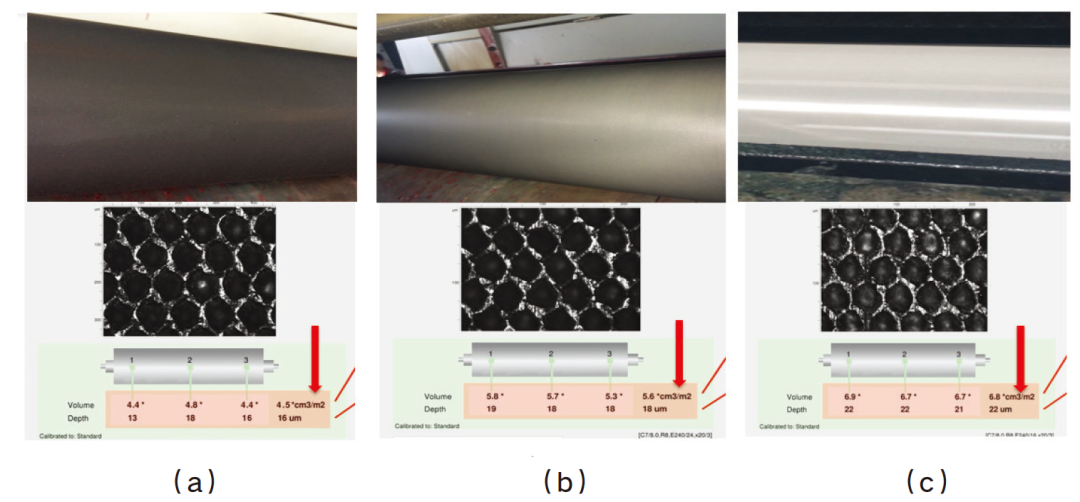

There was once a customer who went to the site to test their mesh roller and found that it was severely clogged. They only cleaned the surface of the mesh roller very thoroughly. Test the three states of this mesh roller. The following figure (a) shows the mesh roller cleaned by the printing company itself, with a mesh depth of 16 μ m and an ink volume of 4.5cm3/m2; The following figure (b) shows the results of manual cleaning using cleaning solution, with a mesh depth of 18 μ m and an ink volume of 5.6cm3/m2 after cleaning; The following figure (c) shows the cleaning process in an ultrasonic device, and the test results show a mesh depth of 22 μ m and an ink volume of 6.8cm3/m2. It can be seen that printing companies believe that the ink carrying capacity of the mesh roller, which has been thoroughly cleaned, has increased by 50% after thorough cleaning.

Different cleaning methods bring different cleaning effects

It can be seen that doing a good job in daily cleaning, adhering to regular cleaning, and correct deep cleaning are the key to improving the service life of the mesh roller and increasing printing efficiency. At present, most printing companies have not yet tapped into the potential of high-quality mesh rollers. Therefore, starting from doing a good job in cleaning mesh rollers, we believe that it can bring printing companies a much higher return on investment than investing in a single mesh roller.

02

Regularly inspect the mesh roller

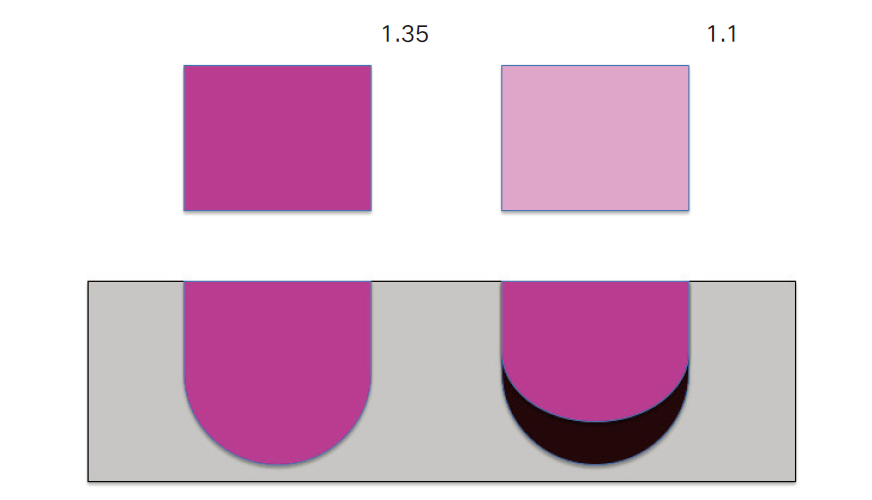

After a new mesh roller arrives at a printing company, it often comes with original test data. However, during use, the mesh holes become clogged, and the ink load inevitably decreases due to long-term high-speed contact and wear with the scraper. Different ink loads (cm3/m2) printed with the same ink will have significant color differences, as shown in the figure.

Therefore, after cleaning the mesh roller, it is necessary to conduct necessary tests for future use. Generally speaking, there are two methods: appearance inspection and detection instrument inspection. Appearance inspection mainly checks whether the surface of the mesh roller is clean, whether there is damage, abnormality, etc. The main purpose of using a detector is to check whether the mesh holes and mesh bottoms are clear, whether the mesh walls are intact and worn, and to make corresponding records. In addition, regular inspections should be conducted on sleeve mesh rollers that are not used for a long time during storage.

03

Proper installation and storage

Improper installation or disassembly, poor storage environment, etc. can easily cause wear, deformation, and damage to the mesh roller, reducing its service life. Therefore, in the daily operation and storage process of the mesh roller, it should be placed in a dedicated box or suitable rack, stored in a dry and ventilated room, and protected with a protective cover. When replacing the mesh roller, it should be prevented from colliding with other hard objects. Special handling vehicles should be used during transportation to avoid dropping due to the heavy mesh rollers, which can prevent the majority of accidental collisions.

In summary, correct and comprehensive management of mesh rollers can extend their service life, ensure stable production operation, and bring huge cost savings to printing enterprises. By managing the ink volume of the mesh roller correctly, the number of sample runs can be reduced, saving time and even producing an additional order. It can also make the standardization of flexographic printing process management easier.