Who is responsible for the pre press printing process in the printing bar issue?

Print quality is the lifeline of printing enterprises, and stripe problems are one of the common issues that affect print quality. The problem of stripes is usually manifested as a series of deep or shallow line like imprints parallel to the axis of the roller on the printed product, which affects the aesthetics and professionalism of the printed product. In this article, the author will explore the causes, troubleshooting, and solutions of the bar problem through a production case.

Troubleshooting and Solutions for Printing Bar Issues

Our four-color machine operator noticed a faint stripe on the fixed position of a product cover during printing (Figure 1). After trying various conventional operations, the operator was unable to eliminate the bar. After discussing with the operator, they believed that there were quality defects on the surface of the CTP printing plate of the product, specifically manifested as missing dots on the surface of the blue CTP printing plate, resulting in uneven ink application and the formation of bars. Due to the urgent demand for the printed product, a consensus was reached and the pre press process was immediately notified to produce a new blue CTP plate. The operator replaced the plate and restarted the printing process, and the problem with the fixed position bar disappeared. At this point, the problem has been resolved, and the product can continue to be printed and undergo subsequent supporting production.

Figure 1 Printed Product Bar

Figure 1 Printed Product Bar

Afterwards, the operator determined that it was due to quality defects on the surface of the CTP printing plate of the product, which affected the normal production of the machine. Therefore, they reported this information to the pre press process and requested a clear response from the pre press process. After receiving feedback on the quality issues of the bars in the prepress process, immediately organize the employees of this process to study and analyze the surface quality defects of the printing plate, identify the reasons for the formation of surface defects on the printing plate, and avoid similar situations in the future.

Firstly, the pre press process contacted the CTP plate supplier through the supply department to understand the quality control situation of this batch of CTP plates during the production process. After receiving quality assurance from the supplier, the pre press process operators reorganized the production process of the pre press process and CTP plate publishing, as well as the storage of CTP plates before and after production in the pre press process, all of which showed normal production.

After ruling out possible surface quality defects of the cover product caused by improper use of raw materials, operation, and storage, the pre press process personnel also inspected the original electronic file of the cover product. After the computer operator searched for the customer's original transmission file, it was found that the color of the flat screen in the same position of the original electronic file of the product was uniform, and there was no obvious lack of screen bars. It can be ruled out that the printing bars were caused by defects in the original electronic file.

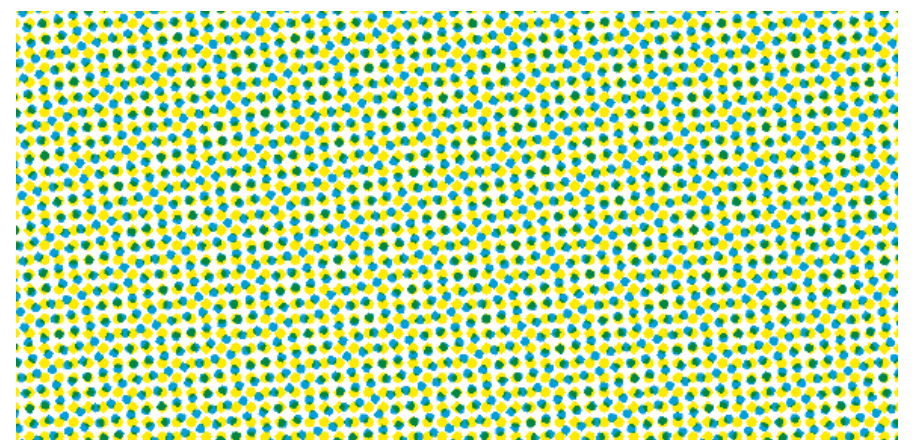

Subsequently, the prepress operator carefully examined the two CTP plates feedback from the printing machine (the blue CTP plate that the machine considered defective and the yellow CTP plate that was considered normal for printing). At the same time, the prepress operator hangs the original electronic file on a screen for color separation preview during the prepress operation process, and compares the flat screen color (composed of yellow and blue dots, as shown in Figure 2) where the printing bars appear.

Figure 2 Preview of network points after color separation

By using dot measurement equipment to separately inspect the yellow CTP plate after normal printing and the blue CTP plate that was considered defective before printing, it was found that there were no missing yellow and blue flat screen dots at the same position, nor was there a faint stripe. Therefore, it is suspected that the accuracy of the information about the surface quality defects of the plate feedback from the printing process is due to whether the printing stripes of this product are caused by surface defects of the CTP plate?

Just as everyone was lost in thought, a CTP publisher sent a message. During the process of communicating and investigating the cause of the stripes on the printing machine, the publisher found that the stripes on the samples with stripes became more obvious and the shape became clearer and more regular as they were flipped forward. It was not until they reached several samples that had just started trial printing that the stripes were all clear and recognizable.

At the same time, in order to completely eliminate the feedback on the surface quality defects of the printing process, the prepress process needs to re-examine whether there may be dot damage on the defective CTP plate that cannot be identified by the dot measurement equipment? Therefore, during the idle period of the printing machine, the original yellow and blue printing plates that were feedback were specially re printed and tested. The test results were consistent with the expected results of the pre press process investigation and analysis - the obtained printing samples did not show any stripe marks.

Based on this, the prepress process confirms that the feedback regarding the stripe information caused by the quality defects of the printing plate is not related to the electronic files of the prepress process or the surface of the CTP printing plate.

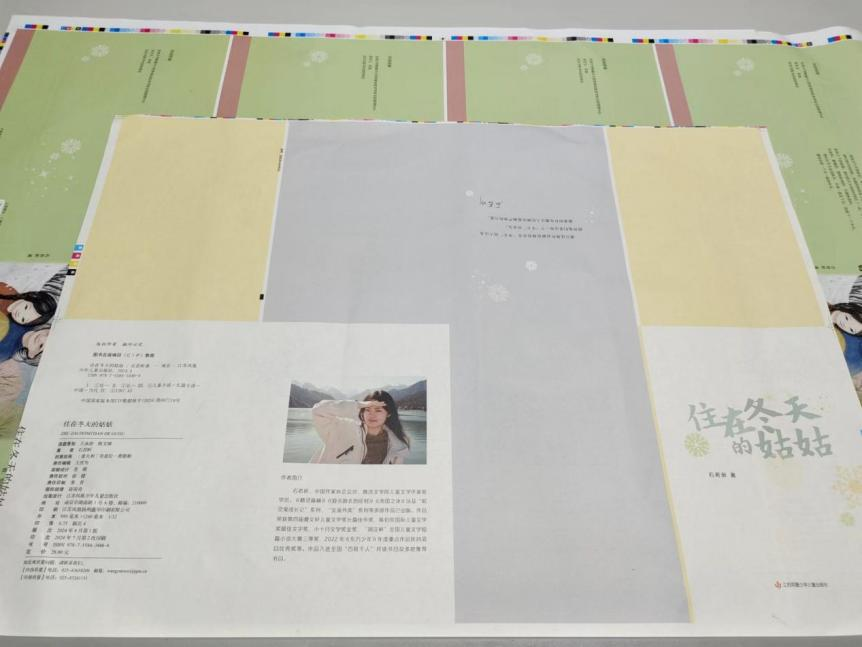

In order to investigate the true reason for the formation of the bar, the pre press process humbly consulted the quality inspection department and professionals in the printing process. With the guidance of the two departments, the pre press process also reviewed the production record book of the machine and found that before printing the cover large edition (split edition) on the machine, the machine printed a pair of (four open edition) color inserted large editions of the same book. By comparing the paper size of the two printed products before and after, it was found that the outline of the stripe marks on the problematic sample was exactly the same as the size on the four color plug-in large plate sample (Figure 3).

Comparison of Cover Sample Traces and Color Insertion Sample Sizes in Figure 3 (Top for Cover Large Version Split, Bottom for Color Insertion Large Version Four Split)

Combined with the quality inspection department's in-depth visits and exchanges with the machine, the pre press process personnel also found that the operator of this printing machine did not adequately clean and maintain the water, ink rollers, and rubber rollers when printing the color inserted large plate (four open plate) and then the cover large plate (double open plate). Usually, when the machine switches from one layout to another, especially from a smaller layout to a larger layout, the printing machine needs to go through a series of meticulous cleaning work to ensure that the new layout can be printed smoothly without being affected by residual ink and paper edges from the previous layout.

However, in this case, it is clear that the cleaning work of the operator was not thorough enough, resulting in the appearance of bar marks on the cover large plate that are the same size as the four color plug-in large plate. This not only affects the printing quality of the cover print, but may also potentially interfere with the subsequent production process and supporting work.

Experience in Solving Printing Bar Problems

In order to solve this phenomenon, the company immediately organized on-site learning for printing process employees. The example of this product requires all machines to be taken seriously and inspected one by one. Machines with similar problems must be thoroughly cleaned of key parts such as the rubber cylinder, water, ink roller, and printing plate of the printing machine. At the same time, further training was provided to frontline operators, emphasizing the importance of cleaning during plate switching and establishing stricter cleaning and color calibration procedures.

After a period of downtime for maintenance and adjustment, our company restarted the printing machine and conducted a trial printing. This time, the printing quality of products similar to cover large editions has been significantly improved, and machines with similar problems such as stripe marks have been effectively solved. Through this case, we have summarized the following experience and insights.

Overview of the 01 Bar Issue

The issue of stripes may be caused by various factors, including but not limited to the handling of prepress documents, CTP plate quality, and adjustments to printing machines. Solving the stripe problem requires close coordination and in-depth analysis between the pre press and printing processes.

Analysis of the causes of the 02 bar problem

机翻 · 通用领域

(1) Pre press file processing: The color settings and resolution of electronic files may affect the printing effect.

(2) CTP printing plate: The quality of the plate material and the integrity of the dot restoration may affect the quality of the printed product.

(3) Printing machine adjustment: It is necessary to accurately adjust detailed parameters such as printing pressure, ink volume control, and drum clearance.

(4) Printing environment: Environmental factors such as temperature and humidity may also affect the printing effect.

Method for troubleshooting 03 bar issues

(1) Check pre press documents: Ensure that electronic files are free of defects.

(2) Check CTP printing plate: Confirm the quality of the plate material and the integrity of the dot restoration.

(3) Analyze the printing machine: check the printing pressure, ink volume, drum gap, etc.

(4) Reviewing samples and production records: Analyzing the evolution process of the bar problem is crucial.

(5) Test printing: Confirm the problem by re printing and testing on the machine.

Some suggestions for enterprises

After investigating, analyzing, and resolving the cause of the stripe issue, we have come to a profound understanding of the importance of close coordination between the pre press and printing processes. To ensure the quality of printed materials, we propose the following suggestions.

(1) The pre press process should strictly control the quality of electronic files to ensure that color settings, resolution, and other parameters meet printing requirements and avoid printing defects caused by pre press file issues.

(2) CTP publishers should carefully inspect the quality of the plate material and the integrity of the dot restoration to ensure that the CTP plate is defect free. At the same time, regular maintenance and upkeep of CTP equipment should be carried out to ensure stable operation.

(3) Printing machine operators should strictly follow the operating procedures, accurately adjust parameters such as printing pressure, ink volume, and drum clearance to ensure printing quality. When switching layouts, the printing machine should be thoroughly cleaned and maintained to avoid residual ink and paper edges affecting the new layout.

(4) Printing enterprises should establish strict quality management systems, strengthen communication and collaboration between pre press and printing processes, and jointly solve various problems that arise during the production process. At the same time, regular employee training should be organized to improve their professional skills and qualities, and to strengthen communication and learning between pre press and printing process employees.

By implementing the above suggestions, we believe that printing companies can effectively reduce the occurrence of common quality problems such as stripes, improve the quality of printed materials, meet customer needs, and enhance their competitiveness.