Just one move! Improved hot stamping process for cigarette packs, easily achieving quality and efficiency improvement

Industry Perspective: Multiple Challenges and Opportunities in Cigarette Packaging Production

As the image card of tobacco products, cigarette packs carry the responsibility of brand communication, and their visual effects directly affect consumers' purchasing decisions. This requires cigarette packs not only to have high-end craftsmanship quality, but also to have excellent recognition and certain anti-counterfeiting performance. The electroplated aluminum foil hot stamping process transfers the metallic texture of the electroplated aluminum foil to the surface of the printed product through precise temperature and pressure control. Its characteristics perfectly meet the needs of cigarette packaging in terms of process, recognition, and anti-counterfeiting performance, and are therefore widely used in cigarette packaging production.

As an important subdivision of packaging printing, cigarette packaging printing has the characteristics of large production batches and high quality standards. Under the policy guidance of "practicing thrift and opposing waste", the tobacco industry has been deeply engaged in improving quality, reducing costs, and increasing efficiency for many years, and has now entered the stage of overcoming difficulties. In this regard, cigarette packaging printing enterprises urgently need to innovate technology, optimize process flow, and deeply tap their own potential to cope with multiple challenges such as customer demand upgrades and increased cost pressures.

At present, the hot stamping process of cigarette packs mainly presents four characteristics: multiple hot stamping points, fine hot stamping patterns, rich and diverse hot stamping materials (such as plain foil, laser foil, anti-counterfeiting foil, etc.), and the interweaving and integration of multiple processes (such as hot stamping first and then offset printing, hot stamping first and then screen printing, etc.). With the comprehensive application of QR code technology in cigarette packaging printing, customers have put forward higher requirements for process accuracy and delivery time. In this context, how to achieve efficient utilization of electroplated aluminum materials and steadily improve production efficiency has naturally become the core focus of various enterprises in the hot stamping process.

Problem Analysis: Material Waste Dilemma of Direct Pull Method in Special Situations

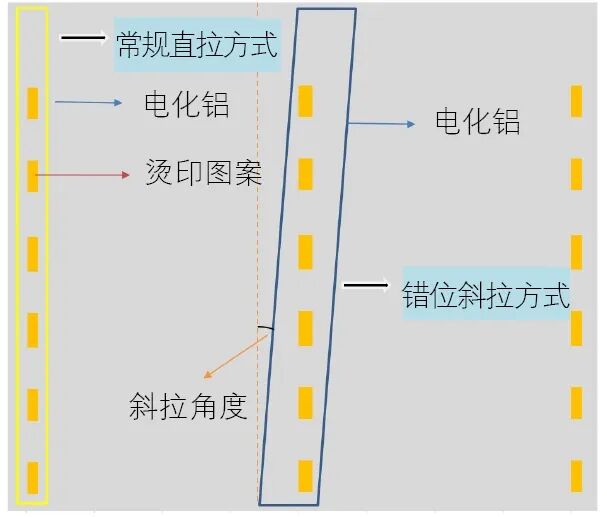

The amount of aluminum used is mainly determined by the width of the aluminum and the length of the aluminum jump step. In the conventional direct drawing method, the width of the aluminum foil is equal to the width of the hot stamping pattern plus the margin on both sides (the margin on both sides refers to the margin reserved for the width of the aluminum foil to prevent incomplete hot stamping on both sides of the pattern caused by the swinging of the aluminum foil during production, which is 6-10mm wider than the hot stamping pattern). But when the hot stamping pattern is narrow (such as the "square" hot stamping pattern in Figure 1, which is only 7mm wide), and the hot stamping process needs to run at a high machine speed of 6000 sheets per hour, in order to ensure that the electroplated aluminum after high-temperature baking does not have abnormal situations such as aluminum foil deformation, hot stamping weight or even foil breakage during the pressure driving process of the foil feeding wheel, the width of the electroplated aluminum has to be increased to 20mm or more.

Referring to the above data (excluding the step skipping of aluminum plating), based on a margin of 10mm on both sides, the utilization rate of aluminum plating is [(7+10)/20] × 100%=85%; If calculated based on a margin of 6mm on both sides, the utilization rate of electrolytic aluminum is only [(7+6)/20] × 100%=65%.

Figure 1 Example of Conventional Straight Pulling Method and Misaligned Diagonal Pulling Method

The improvement of the inclined drawing process for aluminum electroplating is a customized aluminum electroplating method designed to enhance the utilization rate of aluminum electroplating while ensuring smooth operation of the electroplating process in the special situation where the hot stamping pattern is relatively narrow. As shown in Figure 1 "Misalignment oblique drawing method", by adjusting the inclination of the aluminum foil on the hot stamping honeycomb plate, the aluminum foil can be improved from the conventional straight drawing method to the oblique drawing method, which can cleverly utilize the blank area on the back side of the oblique drawing for misalignment hot stamping, thereby achieving more efficient utilization of aluminum foil.

Verification implementation: comparison of pre - and post data and sharing of practical experience

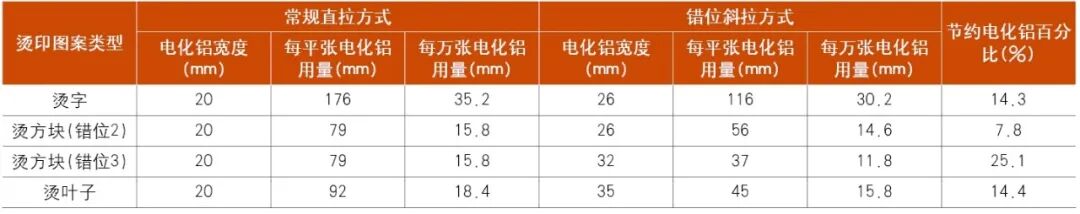

Figure 2 visually illustrates the layout of flat sheet single row hot stamping positions for multiple cigarette pack products, as well as a comparison of the actual hot stamping effects of aluminum foil under conventional straight pull and staggered diagonal pull methods. Table 1 further verifies the difference in the amount of aluminum used by multiple products when using conventional straight drawing and staggered diagonal drawing methods through detailed data comparison, providing solid data support for the effectiveness of this improved method.

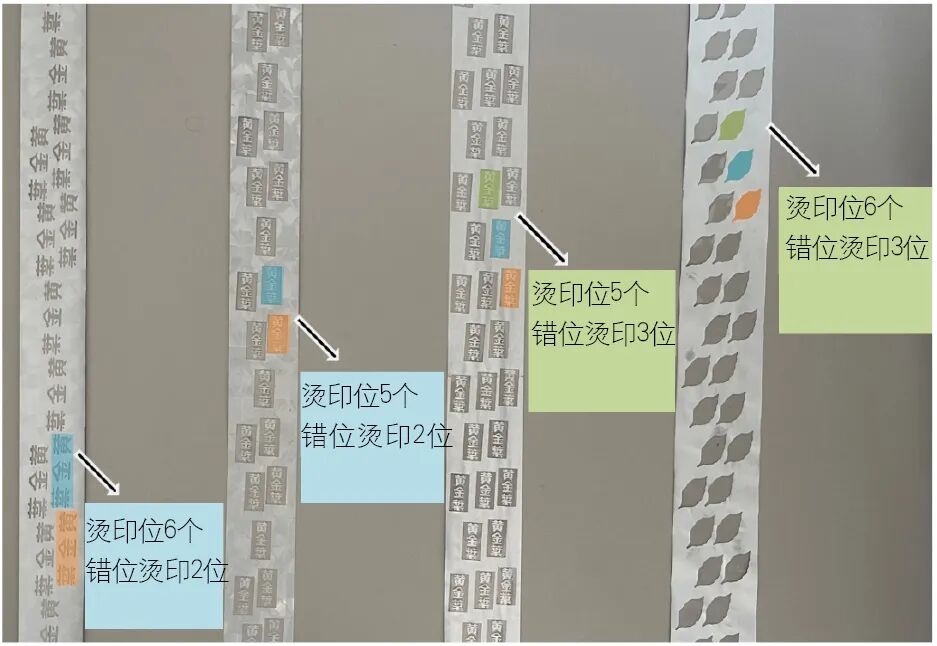

Figure 2: Effect pictures of hot stamping positions and conventional straight pull and misaligned diagonal pull for multiple cigarette pack products

Table 1: Aluminum Consumption and Comparison between Conventional Straight Pulling Method and Misaligned Diagonal Pulling Method

In practical operation, the number of misalignment in oblique hot stamping is not fixed, but needs to be adjusted according to the utilization rate of aluminum and the actual hot stamping effect. Figure 3 presents a comparison of the application effects of multiple products with different numbers of misalignment during oblique hot stamping. It can be seen that an increase in the number of misalignment will be accompanied by a widening of the aluminum foil surface and an increase in the slope. Although this can improve the utilization rate of aluminum foil to a certain extent, the probability of folding, wrinkling, swinging, and hot stamping heavy positions (mostly horizontal overlap between misaligned patterns) occurring during high-speed operation of the equipment will also increase accordingly. Therefore, it is necessary to comprehensively and comprehensively consider various factors, balance the relationship between the utilization rate of aluminum electroplating and the smooth operation of hot stamping, and ensure the optimal production effect.

Figure 3 Comparison of application effects of different misalignment numbers for multiple products during offset oblique hot stamping

In terms of jump step calculation, although there are differences between the calculation method of aluminum misalignment diagonal pull and the conventional straight pull method, the core principle is the same. When calculating the skip step, simply subtract the number of offset hot stamping positions from the original number of hot stamping positions to obtain the number of offset diagonal hot stamping positions. The length of the original hot stamping pattern and the spacing between the original hot stamping positions remain unchanged, and the skip step calculation is still carried out according to the conventional straight drawing method. As for the horizontal spacing between the two misaligned hot stamping positions, it can be achieved by adjusting the angle of the aluminum foil diagonal pull.

It should be noted that due to the fact that the step length (a) of the aluminum foil is calculated based on the straight pull mode, there may be a deviation between the preset step length (a) and the actual aluminum walking length (c) when operating in the inclined pull mode

If the diagonal angle is A, then a=c × cosA. When A=0, a=c; When A>0, c>a.

This deviation will cause the actual hot stamping results on the aluminum foil to be inconsistent with the expected effect when setting the jump step. At this point, the operator needs to repeatedly try and adjust the original hot stamping pattern length, hot stamping position spacing, longitudinal hot stamping pattern spacing, and other data based on the hot stamping results of the aluminum foil, so that the hot stamping spacing, jumping steps, and other parameters of the aluminum foil meet the operational requirements of the hot stamping process, ensuring the stability of product quality and the smoothness of the production process.

Innovation is not unattainable, it is hidden in every detail of daily production. A spark of inspiration, a small process adjustment, can bring about significant changes. Innovation is the core driving force and cornerstone of competitiveness for enterprise development. We should encourage employees to continue exploring, accumulate small innovations for big breakthroughs, and jointly promote enterprises and industries to reach new heights.