ISO standard 12647-6 for flexographic printing

Flexographic printing is a long-standing printing technique that uses flexographic plates and ink to transfer images or text onto a substrate. The plate material for flexographic printing is made of rubber or silicone, which has flexibility, hence its name. In order to efficiently and standardly print the content you want, we have introduced the SO 12647 standard.

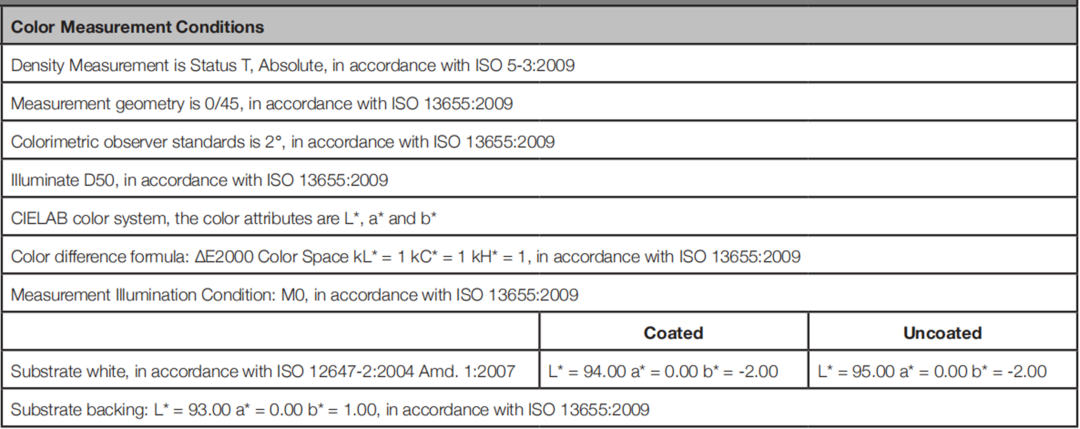

The ISO 12647-6 flexographic printing standard does not define a target value for ink bulk density, but defines a target value for the hue angle of bulk ink color and a recommended substrate color value. In other words, the measurement focuses on actual color values rather than density.

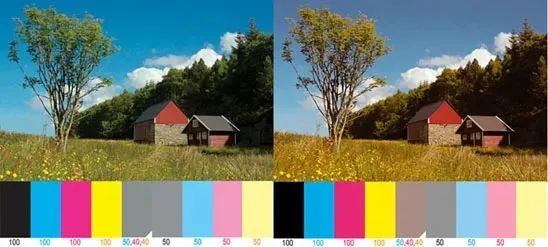

Density cannot be used to distinguish whether colors are accurate.

Density cannot be used to distinguish whether colors are accurate.

If the ink hue is incorrect, although the density may be correct, the color cannot match.

When using many spot colors and extended color sets in the flexographic printing workflow, another set of standards is rapidly gaining popularity, namely ISO 20654- Printing Arts - Measurement and Calculation of Spot Color Tone Values. Although this standard was initially developed only for spot colors, in some cases it is also applicable to printing workflows that use non CMYK colors simultaneously.

Application of ISO 12647-6 standard in flexographic printing

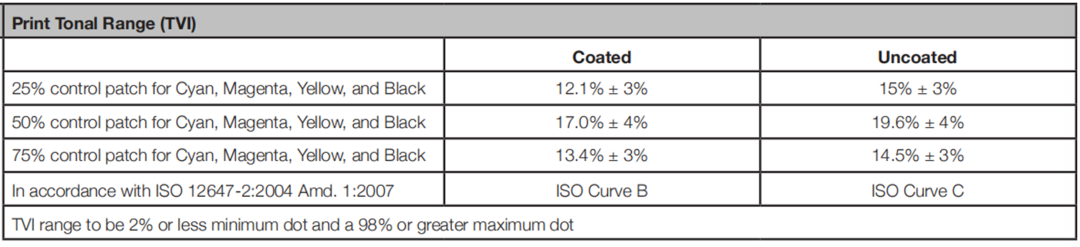

Some graphic art printing standards specify color targets for production on specific substrate types. For example, in offset printing, the paper categories corresponding to these standards, as well as the accurate L * a * b * values, target tone value increase, or TVI (also known as dot enlargement) for solid ink and overlay printing, are all very clear. In flexographic printing, ISO standards only provide recommended phase angles for these colors, and the optimal L * a * b * target values for specific substrates are determined by the printer themselves.

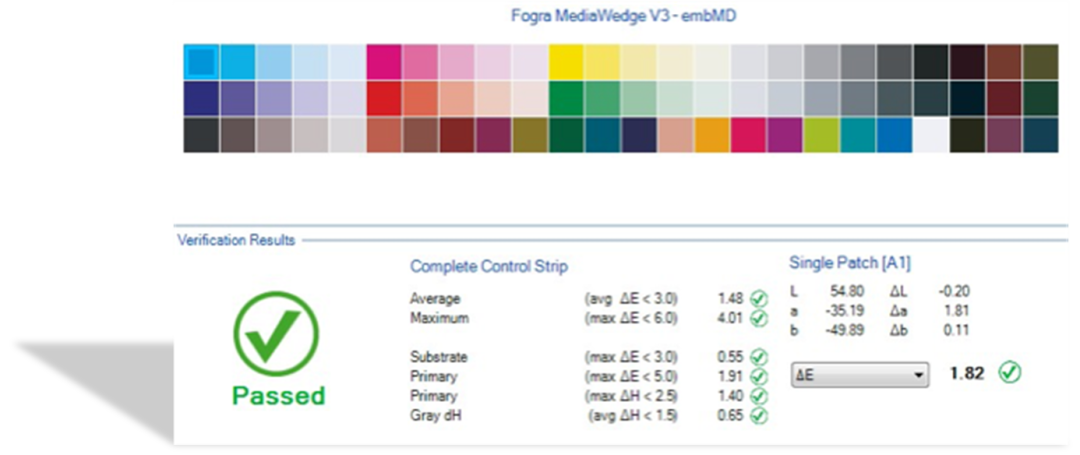

In order to comply with the requirements of ISO 12647-6, only the hue angle of the ink and the L * a * b * value of the substrate color are not sufficient. The production target must also include specific L * a * b * values for on-site ink and overlay printing, as well as TVI values. These values can be published target values or custom target values developed for your printing machine.

The first or possibly simple option is to optimize and characterize the printing machine to match the published 'reference printing conditions'. There are currently 7 new reference printing conditions, each containing different color gamut of the printing machine. These reference conditions are defined as CGATS-21-2-2013 and are part of the proposed ISO standard. The goal is to optimize and characterize the printing machine to approach one of the seven printing conditions. The next step is to adjust the field density to match the L * a * b * values with similar reference printing conditions, and then calibrate the printing plate to achieve appropriate TVI.

Some reference printing conditions are based on other standards, such as rotary offset printing on copperplate paper. In the past, flexographic printers often matched established color specifications with offset printing standards such as SWOP, GRACol, or FOGRA39. Now, with new reference printing conditions, printers can find reference printing conditions that can be more easily matched with specific substrates and printing machine conditions.

In some cases, the printing substrate may differ significantly from all reference printing conditions, so printing businesses must establish a custom set of goals. At other times, customers may require color accuracy higher than what can be achieved using reference printing conditions. In these cases, the optimization and characterization of printing machines will be limited by various published reference printing conditions and pushed towards practical sustainable production limits. If the color production of the printing machine needs to be completed on this substrate, an additional step must be performed - printing machine characterization. This will generate a prepress ICC configuration file, which includes appropriate color separation and sampling that can simulate printing machine conditions.

It is important to remember that standard production target values must be established for each operating condition of the printing machine.

Other ISO standard resources for flexographic printing

The headquarters of the Flexographic Technology Association (FTA) is located in North America and has established branches in Europe. They developed a specification manual called FIRST. This is a powerful tool suitable for all flexographic printing workers, as it includes basic guidelines for high-quality printing according to the ISO 12647-6 flexographic printing standard.

The European Flexographic Industry Association (EFIA) is another resource for guidelines and manuals on flexographic printing practices.

Aiseli Color Services can provide a two-day printing process control seminar to help flexographic and offset printers understand and implement measurement based process control.

Featured Flexographic Color Management Solution

X-Rite eXact: The eXact series is designed specifically for printers and packaging service providers, including various equipment ranging from simple density meters to advanced spectral measurement instruments, and can be widely used for paper, film, and other substrates.

PantoneLIVE Production: With PantoneLIVE Production, pure spectral values of spot colors can be used throughout the entire production process to ensure accurate and reproducible colors, regardless of substrate, printing technology, or ink type.

InkFormulation software: InkFormulation software is a fast, accurate, and consistent solution for ink formulation, recipe creation, storage, approval, and retrieval, suitable for offset, flexographic, gravure, and screen printing inks.

The GMG Flex Proof flexographic printing proofing system can accurately simulate the printing effect before the flexographic printing machine, thereby improving the efficiency of proofing. Four color, spot color, and gray balance can be accurately simulated, and even the printed dots, white and background of the substrate, including small dots that cannot be reflected by the flexographic printing machine, can be removed and sampled before printing.

文档

图片

203/1000

实时翻译

What is ISO 12647 standard for real-time translation of document images 203/1000? The ISO 12647 standard is a set of graphic art standards specifically defined by the International Organization for Standardization for printing, consisting of the following nine parts: Part 1: Printing parameters and measurement methods Part 2: Offset printing Part 3: Newsprint cold set offset printing Part 4: Gravure printing Part 5: Screen printing Part 6: Flexographic printing Part 7: Sampling process using digital data directly Part 8: Verification of printing process using digital data Part 9: Offset metal decoration printing process Bilingual comparison notes Translation What is the ISO 12647 standard? The ISO 12647 standard is a set of graphic art standards defined by the International Organization for Standardization specifically for printing, consisting of the following nine parts:Part 1: Printing Parameters and Measurement MethodsPart 2: Offset PrintingPart 3: Newsprint Cold Fixed Offset PrintingPart 4: gravure printingPart 5: Screen PrintingPart 6: Flexographic PrintingPart 7: Sampling process using digital data directlyPart 8: Verification of Printing Process Using Digital Data DirectlyPart 9: Offset Metal Decorative Printing Process Bilingual notes

划译

What is ISO 12647 standard?

The ISO 12647 standard is a set of graphic art standards defined by the International Organization for Standardization specifically for printing, consisting of the following nine parts:

Part 1: Printing Parameters and Measurement Methods

Part 2: Offset Printing

Part 3: Newsprint Cold Fixed Offset Printing

Part 4: gravure printing

Part 5: Screen Printing

Part 6: Flexographic Printing

Part 7: Sampling process using digital data directly

Part 8: Verification of Printing Process Using Digital Data Directly

Part 9: Offset Metal Decorative Printing Process

Various parts of the world interpret these standards in different ways and incorporate them into their own norms. For example, GRACoL (CRPC6) from IDEAlliance in North America and FOGRA39 and FOGRA51 from Europe are both offset printing specifications that comply with ISO 12647-2 for Class 1 copperplate paper.