How G7 calibration method helps print neutral gray

With the widespread application of printing standardization work, the G7 ® Integrated into global standards for neutral gray printing/printing methods, visual consistency can be maintained regardless of CMYK printing/printing output, such as ISO 19303-1 and 19303-2 for color workflow consistency, ISO 10128 for calibration, ISO 15339-2 for 7 common reference printing conditions, and further integrated into other ISO standards, as the G7 near neutral gray output calibration method continues to be used by printers in over 40 countries/regions worldwide.

Many printing service providers are familiar with the term G7, but what does it actually mean? In short, G7 is a calibration process used to improve color consistency and accuracy between different printing/printing devices. This is an international standard developed by Idelliance, an independent non-profit organization dedicated to promoting industry standards in digital media and print production.

Why is G7 calibration equipment important?

G7 calibration printing is very important as it helps ensure quality assurance for various printing devices. If calibration is not performed, there may be significant differences in the operation of printing machines from different sources due to differences in color management practices. This may result in inaccurate color reproduction or misaligned borders on image and text elements. By using the G7 standard for calibration, you can ensure that no matter which printer/printing machine the print comes from, the print can maintain color consistency and stable quality.

How does G7 calibration equipment work?

The working principle of G7 calibration printing is to replace density based linearization process with grayscale calibration. This calibration process redefines the grayscale from a * 0 and b * 0, starting from the white point of the medium and gradually correcting it inversely proportional to the ink coverage. This is done to reflect a concept called 'chromaticity adaptation'. Manual response will automatically correct changes in white spots. It also introduces Neutral Print Density Curves vs TVI to control contrast or "color tone". This is called 'G7 grayscale'. Fine tuning can be made according to different applications to set L * A * B target values for CMYK and two-color overlay (C/Y, C/M, M/Y). Target L * A * B can be set for any color space and/or ink.

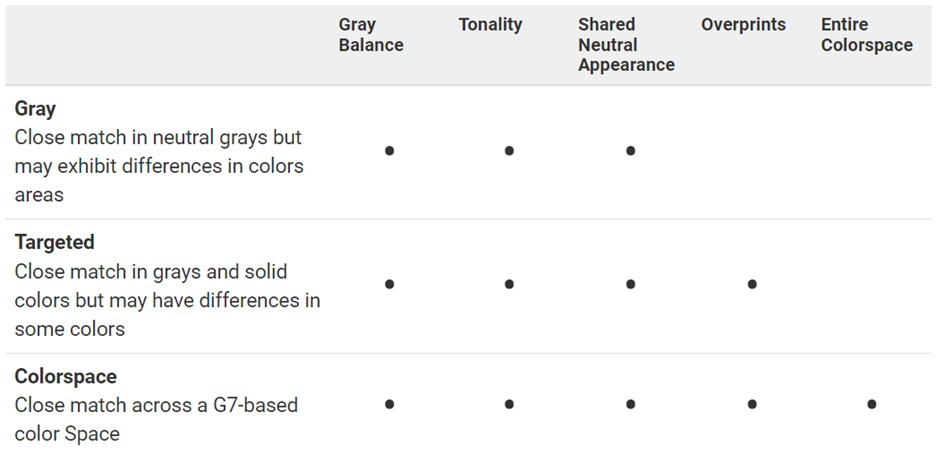

G7 Compliance Level

There is no standard value for G7 compliance. However, in North America, the most common color space used for printing is GRACol. Therefore, most printing machines target colors defined by the GRACol standard when achieving so-called 'G7 Targeted' compliance. Targeted is the compliance level that most offset printing companies target. The highest level of compliance is called 'G7 Color Space'. This compliance level is mainly used for printing equipment or inkjet printers. In addition to simple 1D curves, it usually requires the use of ICC profiles. It uses larger color samples within a specific color space and measures the accuracy of a given device's reproduction space.

What is the difference between G7 and ICC analysis?

G7 is a calibration method that typically uses a 1D curve for each color to achieve grayscale. Depending on the device, ICC profiles may be required to achieve target or color space compliance. ICC is a lookup table used to convert RGB or CMYK values into their corresponding L * A * B values. Due to GRACol and other ISO 12647 based color standards being based on offset printing data, targeted color space compliance can be achieved through simple offset printing curves. Due to different ink standards for other processes such as inkjet, flexographic, and screen printing, ICC profiles can be used in conjunction with G7 calibration to achieve the desired color standards.

How can printing service providers obtain G7 qualification certification?

Printing service providers can collaborate with G7 experts to complete the G7 certification process and submit G7 calibration samples. Many leading technology providers, including kngColor, have Idelliance certified G7 experts who can help you obtain G7 certification in any printing process. We can also provide G7 color management and printing standardization training, allowing printing machine operators to have an accurate understanding of G7 methods and advantages, making process control easier and more intuitive.

G7 ® Experts have demonstrated their expertise in color management, processes, and quality control for sampling and printing using the G7 method. G7 experts are able to implement G7 based calibration and process control in the printing workflow, analyze color and printing related issues, take corrective measures, apply a set of system and process control methods to standards or specifications, and obtain reproducible and predictable results. All G7 experts have participated in and successfully completed the Ideallliance G7 expert training, with a proficiency level of at least 90%.