Do summer labels easily experience 'adhesive overflow'? These influencing factors must not be underestimated!

Spring has come to an end, and the blazing summer is just around the corner. Summer is characterized by high temperatures and humidity, during which non-adhesive labels often encounter issues with glue overflow during production and use, causing considerable trouble for some non-adhesive label manufacturers and end users. In this article, the author will share how to address glue overflow problems in non-adhesive labels during summer.

As we know, the adhesive layer in non-adhesive label materials has a certain level of fluidity, which is greatly affected by temperature. Generally, the higher the ambient temperature, the stronger the fluidity of the adhesive. Once the adhesive becomes more fluid, glue overflow is more likely to occur. This is especially true during the roll-to-roll production of non-adhesive labels, where the material is affected by the machine's running tension and winding tension. If the adhesive's fluidity increases at this time, glue overflow is even more likely under the influence of tension. Common types of glue overflow are as follows and will be analyzed one by one.

01

Glue Overflow at Material Ends or Cut Edges

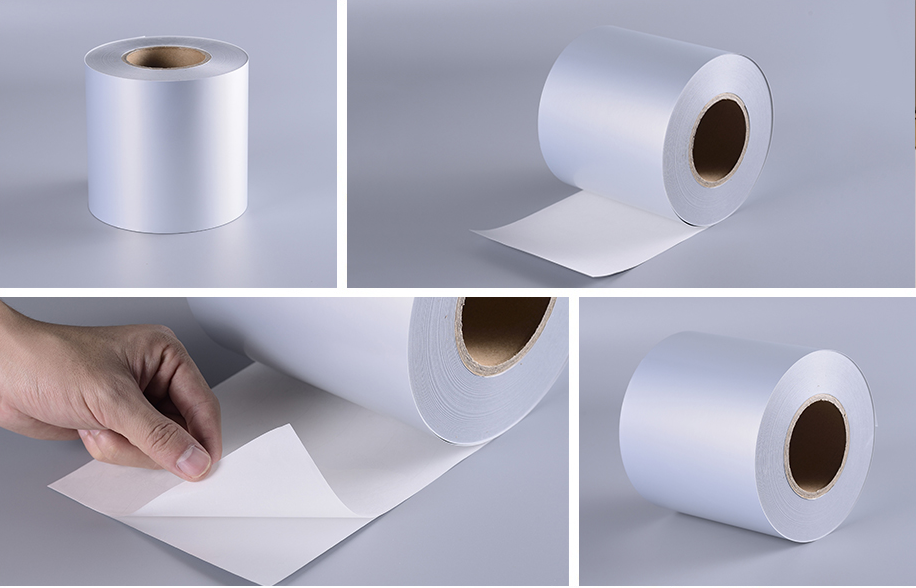

Most non-adhesive label materials are in roll form, with a small amount in single-sheet form. In summer, under the influence of high temperatures, both forms of non-adhesive label materials are prone to glue overflow. Among them, roll-type non-adhesive label materials mainly show glue overflow at the two ends of the roll, while single-sheet non-adhesive label materials mainly exhibit overflow at the cut edges.

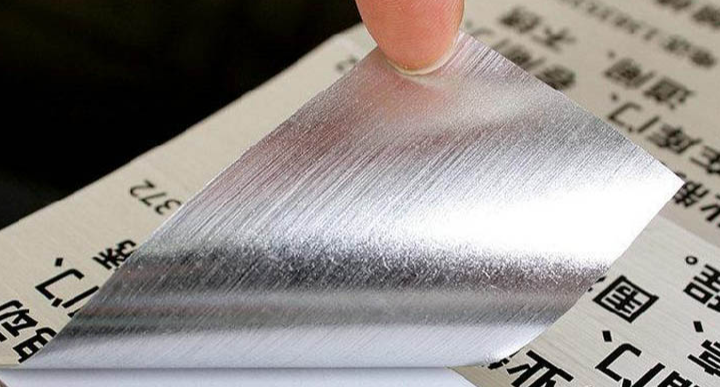

Once non-adhesive label materials experience glue overflow, handling it becomes very troublesome. This is because the excess adhesive can stick to the layer underneath, making it impossible to unwind and print the material properly. For roll material with glue overflow at the ends, during printing, the adhesive on the edges can accumulate on the paper guide rollers of the equipment. Over time, if the glue builds up too much, it can easily tear the material, requiring the machine to stop for clearing, greatly increasing production losses. For single-sheet materials with edge glue overflow, the edges may stick together, causing double sheets, multiple sheets, misaligned feeding, or even paper jams during machine operation.

Therefore, during the summer, adhesive label material manufacturing companies must take preventive measures during slitting to avoid problems caused by glue overflow. First, the slitting blades should be cleaned promptly. Any glue accumulated on the blade surface should be removed in time to prevent it from sticking to the material surface due to excessive accumulation. At the same time, the slitting tension must be strictly controlled. Currently, many slitting machines use sliding roller winding, allowing the tension of each roll to be controlled. Moreover, the machine's winding tension control system can adjust the tension taper in real-time according to the material's winding diameter, ensuring that the material runs at the optimal tension without loosening during winding, avoiding glue overflow caused by excessive winding tension.

In addition, after the material is slit, baby powder can be evenly applied to both ends of the material. This fine powder can create a certain sealing effect on the cut edges of the adhesive material, greatly reducing the possibility of glue overflow on the material edges. For single-sheet material, after slitting, a small amount of fine powder can be applied to all four edges to reduce the likelihood of glue leakage. However, it is important to strictly control the amount of powder because most single-sheet materials are used for offset printing, and excessive powder can cause white spots during subsequent printing.

If an adhesive label material shows edge glue overflow after reaching the printing company, and the overflow is not severe, a silicone oil spray or release agent can be evenly applied to the edges. However, if the overflow is severe and the material cannot be unwound normally, the only solution is to replace the material.

02

Die-cutting Glue Overflow

The main cause of die-cutting glue overflow is also high summer temperatures, which increase the flowability of the glue, causing overflow under the pressure of the die-cutting blades. So, what should be done if die-cutting glue overflow occurs during summer production?

First, efforts should be made to improve the temperature and humidity environment of the production workshop. Generally speaking, the temperature in printing workshops should be controlled between 20°C and 25°C, and the relative humidity should be maintained between 50% and 60%. To achieve these environmental requirements, many printing companies have installed temperature and humidity control systems. In addition, for certain adhesive label materials with particularly high glue fluidity or thickened glue, issues of glue overflow can easily occur in both winter and summer, especially in summer. Therefore, when die-cutting such materials in summer, it is recommended to freeze the materials first, and then take them out and immediately perform inline printing and die-cutting before production. This can effectively prevent glue overflow during die-cutting. 03Glue Overflow on Finished Labels after Cutting into Flat SheetsSome finished adhesive labels need to be cut into flat sheets, usually packaged in hundreds of sheets per batch. In the summer, it is common to encounter glue overflow issues after the labels have been cut and left for some time. Once glue overflow occurs, the labels may stick together, and sometimes the backing paper of the top label can pull off the label underneath, causing inconvenience for the end user.

The main reason for this problem is that stacking hundreds of finished labels together can cause compression. In addition, during summer, higher temperatures increase the fluidity of the adhesive, and under compression, this leads to adhesive overflow. Therefore, it is recommended that printing companies reduce the number of labels per pack in summer to avoid adhesive overflow caused by excessive stacking. At the same time, finished labels should be stored in a cool, shaded place, and excessive inventory should not be accumulated at once. The storage time should also not be too long to prevent adhesive overflow issues.04Improper Storage Causing Adhesive OverflowIn summer, some film-type self-adhesive labels may experience adhesive overflow after being stored for a period of time. Labels with adhesive overflow make a crackling sound when unrolled, and if the label area is small, it can easily be peeled off by the backing of another label. This adhesive overflow problem is often caused by poor storage conditions in the warehouse, where temperature and humidity are not controlled. Therefore, when storing finished self-adhesive labels in summer, especially film-type labels, it is essential to maintain the warehouse's temperature and humidity within an appropriate range, generally in line with the printing workshop's requirements. If this is not possible, a separate small room with air conditioning should be set up in the warehouse to store higher-priced finished labels separately.