Cracking the problem of QR code printing on cigarette packs, these points have become the key to quality!

With the development of new technologies and processes, the application of QR codes in cigarette packaging materials continues to enrich. In order to continuously optimize and solve various printing suitability problems (such as QR code paste, wire drawing, etc.), multi-dimensional and comprehensive experimental exploration is carried out from the parameters of printing equipment in the process of QR code printing. The aim is to formulate requirements for key nodes of output equipment parameters, ensure the effectiveness, standardization, and uniformity of production control and testing from the source, effectively improve the quality of QR code printing, provide customers with higher quality products and service levels, and provide more effective research methods and ideas for the industry.

Variable QR code is a further extension and enhancement of QR code technology in packaging applications. Applying variable QR code printing technology to packaging printing can achieve a unique QR code for every smallest unit of product, truly realizing the concept of "one item, one code". The achievement of "one item, one code" will not only further strengthen the anti-counterfeiting and traceability effect of products, making them accurate to every smallest unit of product, but also enable enterprises to collect user data accurately to individuals, truly achieving personalized marketing of products. In order to continuously optimize and solve various issues related to the suitability of QR code printing, scholars in the industry have conducted many attempts and analyses, aiming to improve product quality while ensuring the stability of QR code quality. In this article, the author will further study the influence of printing parameters on the printing quality of QR codes, in order to better solve quality problems in actual printing.

Ink temperature parameter experiment

The printing equipment used this time is a single sheet inkjet printer, which consists of a mechanical platform (paper feeding mechanism, paper feeding platform, paper receiving mechanism), printing system, photopolymerization mechanism, online inspection system, etc; Its core is the printing system, consisting of a nozzle module, a numerical control system, and an ink supply system. The printing system consists of a numerical control system and an ink supply system, with the core being the control of the ink supply system by an industrial computer. Firstly, the printing software in the numerical control system sets the printing parameter information, which will be processed or converted by the industrial control computer (main control board) and the digital analog system to directly control the nozzle printing work.

Piezoelectric inkjet printing technology belongs to normal temperature and pressure printing technology. It places many tiny piezoelectric ceramics near the nozzle of the print head. Piezoelectric ceramics have the characteristic of bending deformation under the change of voltage at both ends. When the image information voltage is applied to the piezoelectric ceramic, the stretching vibration deformation of the piezoelectric ceramic will change with the change of image information voltage, and the ink in the nozzle will be uniformly and accurately ejected in a stable state at normal temperature and pressure.

In this experiment, with a fixed nozzle, the experimental variable is ink temperature, and the other printing parameters are fixed. On the substrate, the change in the printing sample is measured to determine the effect of ink temperature on the formation, flowability, and diffusion of ink droplets on the substrate. For more convenient testing and estimation of the change in printing size at different ink temperatures, while printing square blocks, test their increment.

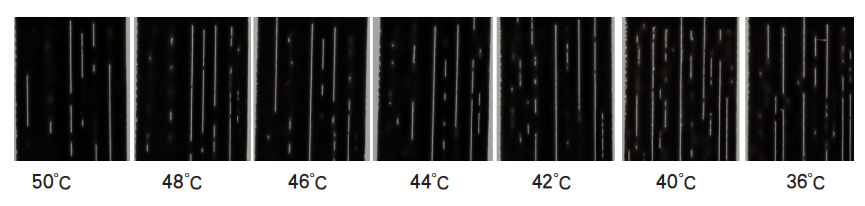

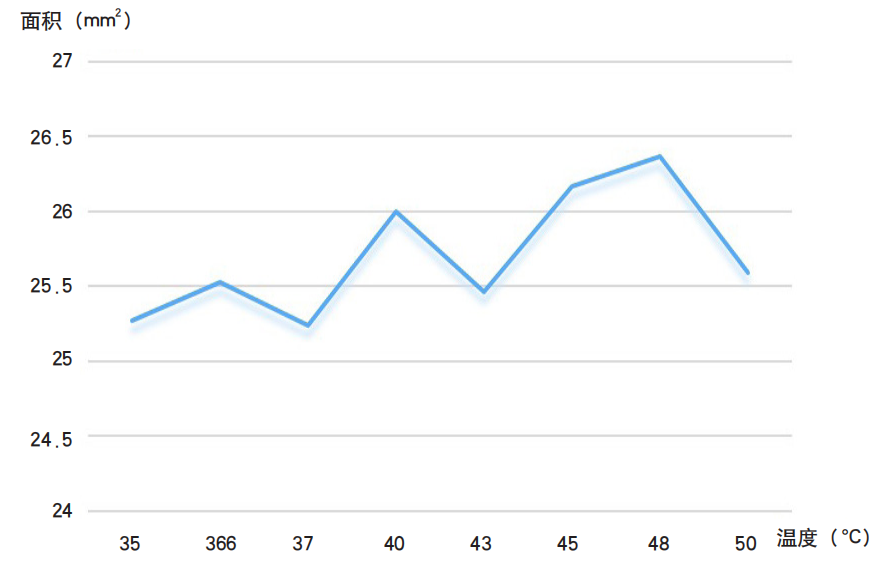

Based on the above tests, it can be concluded that changes in ink temperature parameters can directly affect the printing effect. As shown in Figure 1, as the ink temperature increases, the ink viscosity decreases, the ink flowability increases, and it spreads better to the surface of the printing substrate. The appearance defects (white spots, lines) on the surface of the printed product become smaller. As shown in Figure 2, with the increase of temperature, the dot area or line diffusion of the printed sample does not change much, but the chamfers and burrs on the edges will increase, which visually feels thicker.

Figure 1 Printing effect at different ink temperatures

Figure 2: Changes in Block Area at Different Ink Temperatures

Figure 2: Changes in Block Area at Different Ink Temperatures

Voltage, vehicle speed, nozzle height parameter test

In this experiment, with a fixed nozzle, the test variables were voltage, vehicle speed, and nozzle height, while the other printing parameters were fixed and unchanged. On the substrate, the printing changes of the printing sample were measured to determine the influence of voltage on the collection of main ink droplets, diffusion of "satellite ink droplets", and deformation of the printing image.

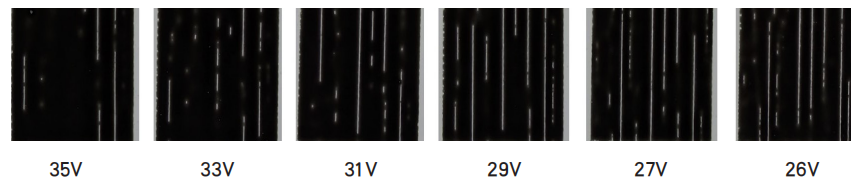

Under the condition of a vehicle speed of 120m/min and an ink temperature of 46 ℃, the variation of voltage printing is shown in Figure 3. From the figure, it can be seen that voltage has little effect on the shape of inkjet printing. However, according to the analysis of the previous principle, under normal circumstances, ink forms a normal plane inside the nozzle. After applying voltage, the ink begins to flow out and then forms a long ink filament. Under the action of surface tension, the ink filament forms an ink droplet. After the interaction between the ink droplet and viscosity, the ink filament breaks and forms inkjet. If the ink filament is too long, it is easy to form satellite dots. When the voltage increases, the larger the ink volume, the higher the initial velocity, and the faster the velocity, the smaller the particles formed, and the stronger the Brownian motion of the particles. At the same time, the shorter the ink filament formed, the easier it is to collect the main ink, resulting in an inkjet printing effect. The better, the thickness will also be relatively higher.

Figure 3 Voltage variation printing effect

Figure 3 Voltage variation printing effect

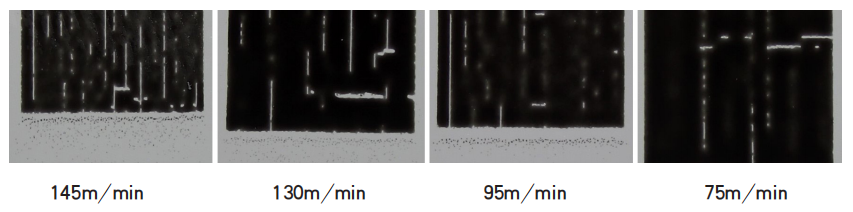

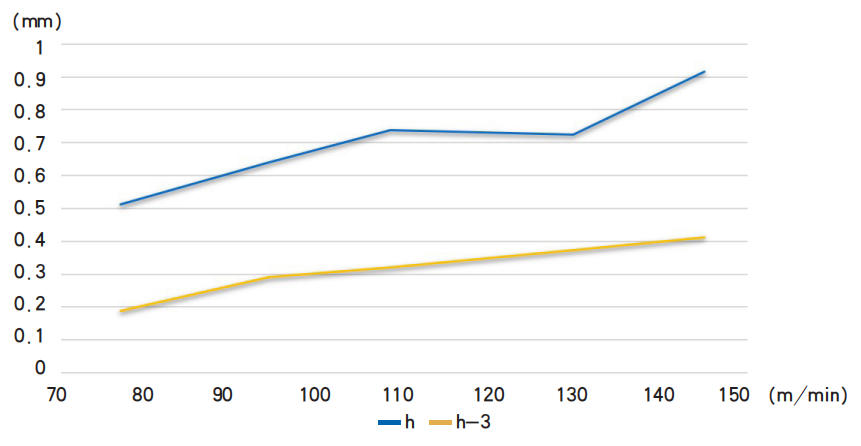

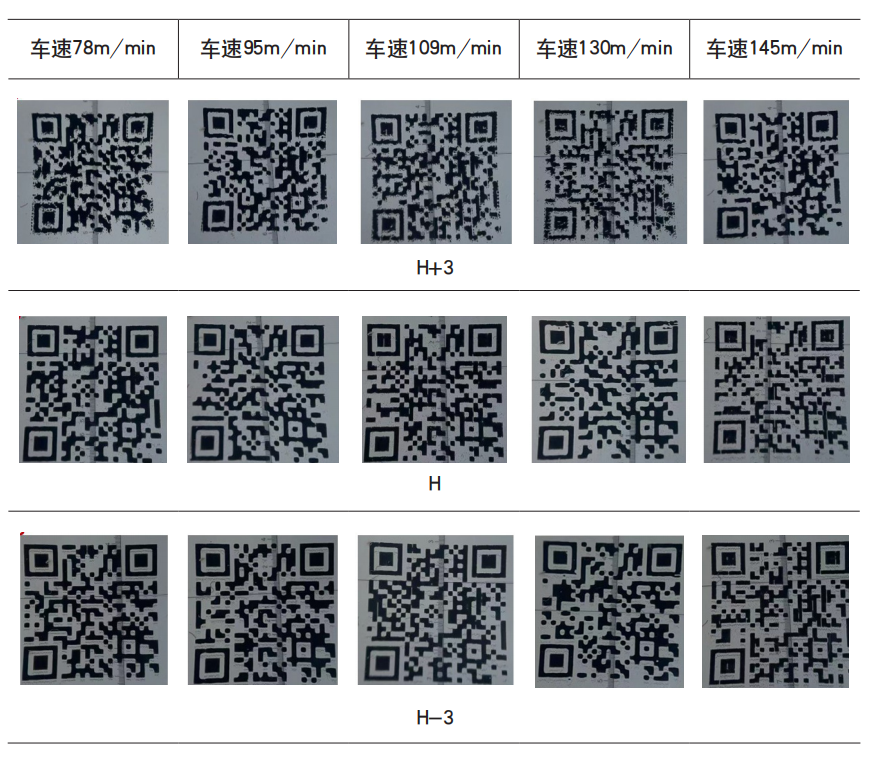

At a voltage of 32V and a temperature of 48 ℃, adjust different vehicle speeds and test the ink droplet aggregation under normal nozzle height, as shown in Figure 4; The comparison chart of ink flying during spraying at different vehicle speeds, normal nozzle height, and 3mm downward nozzle height is shown in Figure 5; The printing effect of QR codes with different vehicle speeds and nozzle heights is shown in Figure 6.

Figure 4: Aggregation of Ink Droplets at Different Vehicle Speeds

Figure 5 Comparison of Ink Flying during Spray at Different Vehicle Speeds, Normal Nozzle Height, and 3mm Downward Nozzle Height

Figure 6 QR code printing effect at different vehicle speeds and nozzle heights

As shown in Figures 4-6, the speed of the vehicle and the height of the nozzle can both affect the collection of the main ink droplets, directly affecting the thickness and deformation of the printed graphics and text, thereby affecting the quality symbol level and appearance of the QR code printing. The higher the nozzle, the longer the ink filament it forms, making it difficult for the main ink to converge. The faster the vehicle speed, the more dispersed the inkjet falls onto the paper, resulting in poor performance. Based on the above process test results, four main process parameters have been summarized and verified: nozzle temperature, nozzle voltage, nozzle distance, and paper feed speed, which have an impact on the printing quality. The characteristics of the printing process have been better understood. Ink temperature and voltage determine the quality of the printing effect (white spots, lines), while vehicle speed and nozzle height determine the collection and flight trajectory of ink droplets (flying ink, thickness).

Conclusion

As the ink temperature on the machine increases, the viscosity of the ink decreases, and the fluidity of the ink increases, it can better spread to the surface of the printing substrate, and the appearance defects such as white spots and lines on the surface of the printed product become smaller. The ink temperature has little effect on the dot area or line diffusion changes of the printed sample, but when the ink temperature decreases, the chamfers and burrs on the edges will increase, which visually feels thicker.

The relationship between printing parameters such as voltage, vehicle speed, printing height, and the formation and stability of ink droplets is as follows: voltage determines the amount of ink to be printed, and the higher the set value, the larger the ink volume. At the same time, the initial velocity of the compressed "satellite ink droplets" is higher, making it easier for the main ink droplets to gather and resulting in better printing effect; The speed of the vehicle and the height of the nozzle can both affect the collection of the main ink droplets. The predetermined droplet trajectory of the ink droplets directly affects the thickness and deformation of the printed text, thereby affecting the quality symbol level and appearance of the QR code printing.