Craftsmen Lecture | How to Reduce Carving Tool Wear in Tobacco Pack Die-Cutting? A Die-Cutting Veteran with 26 Years of Experience Shares His Tricks!

Cutting-edge post-press processes, traditional post-press die-cutting and hot stamping

Mo Yizhong has progressed over 26 years from a printing product finisher and process technician to the head of the stamping mold department. He is thoughtful, innovative, and committed to using multiple methods and comprehensive strategies to reduce costs and increase efficiency. The foil collection device he designed for the hot stamping machine has received a utility model patent. He has successively solved flocking and scuffing problems in the die-cutting of small and strip boxes for Jiaozhi (Red Style), made reasonable use of long-term idle die-cutting plate frames on hot stamping machines, improved the efficiency of convex-concave plate changes, optimized the hot stamping process, and saved 40% of aluminum foil. In 2022, a Labor Model Innovation Studio named after him completed five QC innovation projects and 12 process and technology improvements under his leadership. As a backbone of the enterprise, he has always adhered to the mentorship philosophy of 'It is better to teach someone to fish than to give them fish.'

In today's highly competitive cigarette packaging industry, the demand for packaging quality is also increasing. How to minimize material waste while continuously improving quality is the optimal solution for maintaining a competitive advantage in the current market environment. Reducing material waste is an important part of cost control, and achieving this while maintaining quality requires finding corresponding solutions in the actual production process.

In the die-cutting process of cigarette packaging production, there are many common issues, such as die-cutting knife breakage (which refers to fractures at the point where two blades meet during die-cutting). Ordinary die-cutting blades are relatively easy to handle and can be directly replaced with spare blades, but some special products require the use of an entire carved die. For example, the 'Width & Luck Slim Small Box' products produced by our company require an entire carved die for the small airplane opening.

As orders for this product increased, the frequency of replacing broken carving knives increased, and knife change times lengthened, resulting in higher consumption of die-cutting carving knives and reduced die-cutting efficiency. Based on actual production, I found that the materials for making carving knives in the industry are not uniform, process parameters are not standardized, and design data is incomplete. Therefore, the technical parameters for carving knife production need to be optimized according to actual production conditions.

Introduction and Use of Carving Knives

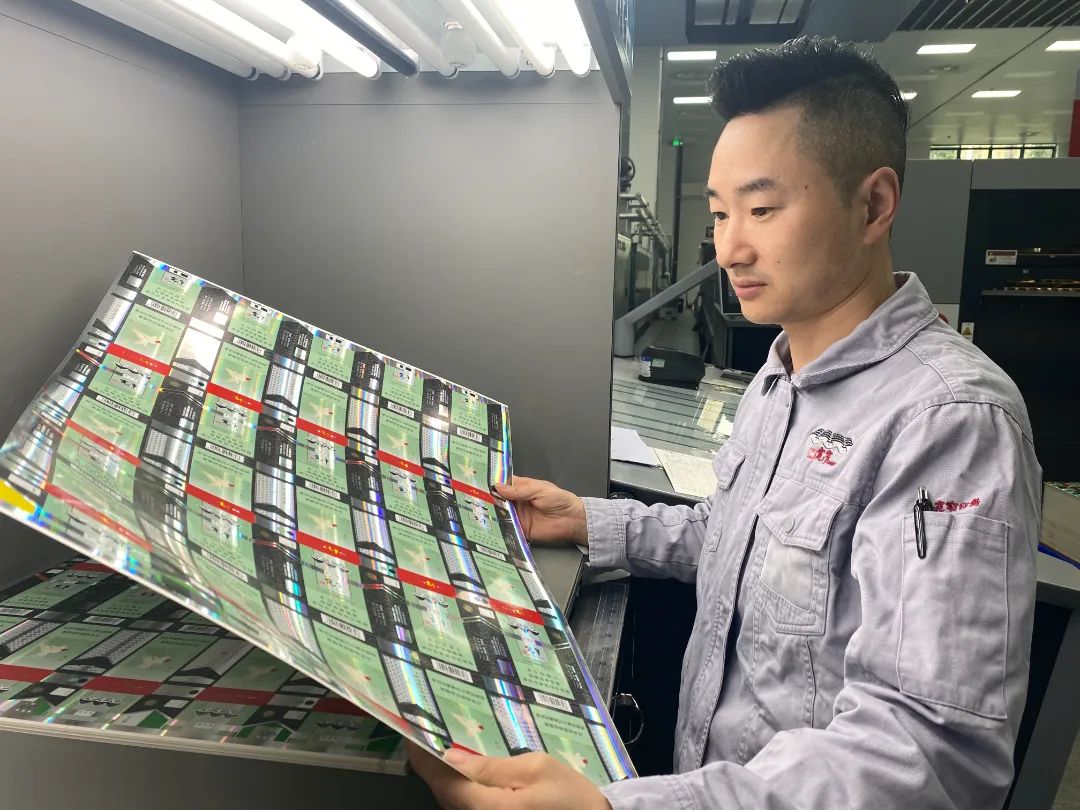

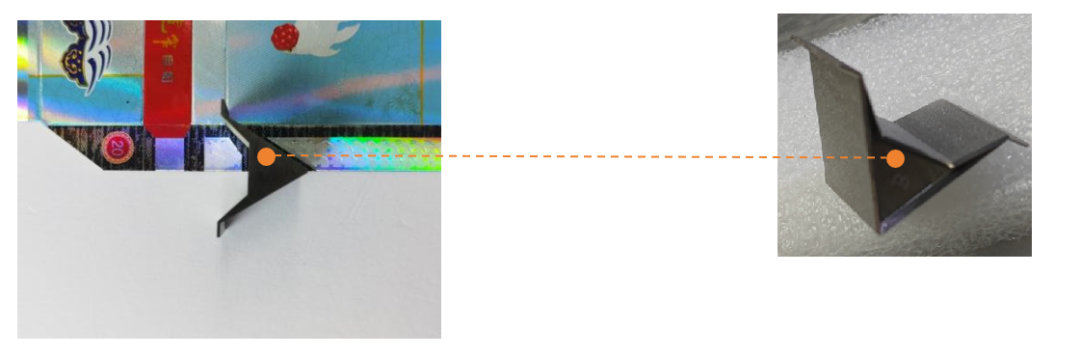

A carving knife consists of two parts: the blade (used for cutting the product's front face) and the base (used to fix it onto the die-cutting bottom plate). The schematic diagram of using a carving knife to cut the small airplane opening of the 'Width & Luck Slim Small Box' product is shown in Figure 1.

Figure 1. Engraving knife used at the small plane opening of cigarette pack products

Figure 1. Engraving knife used at the small plane opening of cigarette pack products

During the production of the 'Kuankuan Haoyun Slim' small boxes, the engraving knife wear is about 10,000–20,000 prints per knife on average. In the production process from April to June last year, April produced a total of 582,000 prints with 42 knives worn; May produced 922,000 prints with 60 knives worn; June produced 1.35 million prints with 95 knives worn. Overall, the engraving knife wear in the three months was about 14,000 prints per knife.

The knife replacement time was approximately 16 hours in April, 28 hours in May, and 38 hours in June. On average, replacing one engraving knife takes about 35–42 minutes to resume normal production. Each shift spends about 1.5–2 hours on knife replacement, reducing the machine production efficiency by around 20%. To identify the key factors affecting engraving knife lifespan and reduce the number of prints per knife to shorten replacement time, the author conducted a systematic analysis from the perspectives of 'man, machine, material, method, and environment.'

01

Engraving Knife Material

Currently, the engraving knives used in the company's die-cutting machines are mainly made of ordinary tool steel, which is too hard and not very flexible. When confirming the knife material with the plate-making manufacturer, it was found that there are no technical standards specified for the engraving knife material, which increases the risk of higher consumption.

02

Engraving Knife Angle

Through on-site investigation, the angle of the engraving knives on the company's die-cutting machines varies between 47° and 48°, and no technical standard has been set for the blade angle, which increases the risk of higher consumption.

03

Paper Thickness

After confirming the supplier material parameters with procurement (the 'Kuankuan Haoyun Slim' small box paper parameters: 237 g/m², 680 mm × 486 mm), it was found that the parameters meet the company's process quality standards, and the batch product quality is stable, posing no risk of increased consumption.

04

Operator Skill Level

Through on-site sampling of employee equipment operation skills, no employees were found to be unqualified; in addition, practical and theoretical skills training for employees is conducted regularly. Therefore, there is no risk of increased consumption due to improper operation.

05

Knife Replacement Operation

Because the engraving knife installation is special, it cannot be replaced like an ordinary die-cutting knife by simply taking it off the front of the die plate. The die plate must be removed from the die-cut frame, the knife knocked out from the front to the back, the new engraving knife installed carefully from back to front, and then the die plate reinstalled into the die-cut frame. This process results in a longer replacement time.

Based on the analysis of the above factors, we conclude that the material and angle of the engraving knife are the main factors affecting its service life.

Formulating Improvement Measures

01

Optimize Engraving Knife Material

By comparison, we replaced the engraving knife material (ordinary tool steel) with special steel molds (HRC), as shown in Figure 2, and adjusted the hardness of the engraving knife.

Figure 2 Material of the Engraving Knife Before Improvement (Top) and After Improvement (Bottom)

02

Improvement of Engraving Knife Angle

The experiment sequentially used engraving knife blade angles from 49° to 53°, divided into 5 groups, with each group undergoing 50,000 impressions. Among them, the engraving knife with a 49° blade angle showed the least wear, while in the other control groups, as the blade angle increased, the degree of wear gradually increased. The experimental results are shown in Table 1.

Table 1 Experimental Results of Different Engraving Knife Angles

03Methods to Reduce Long Knife Change Times

(1) Process the die-cutting plate frame by creating an opening in the steel plate on the back of the die-cutting frame.

(2) When replacing the engraving knife, there is no need to remove the die-cutting mold. Simply remove the steel plate with the opening on the die-cutting frame, tap out the worn knife from the front to the back of the mold, and replace it with a new engraving knife. Replacing one knife takes only about 5–10 minutes, simultaneously improving knife-changing efficiency by approximately 75%.

(3) By improving the die-cutting plate frame, it is also possible to achieve more precise adjustment of the padding for die-cutting knife pressure, making the die-cutting knife pressure more uniform, thereby extending the service life of the die-cutting plate and stabilizing product quality.

Effect Verification

Through the above improvements, we communicated and confirmed the process parameters for the engraving knife with the process technology department and incorporated them into the process regulations as a standard. After conducting trials in August and September and checking for factors that could affect the lifespan of the engraving knife, we replaced the knives with new materials and adjusted the blade angles. Production in October–November showed significant improvements. In October, the output of the 'Kuan Zhai Haoyun Slim Box' was about 1.5 million prints with 35 knives consumed; in November, 1.1 million prints were produced with 26 knives consumed. The total knife usage was 42,600 prints per knife.

Before optimization, the small 'Kuan Zhai Haoyun Slim Box' required about 14,000 prints per knife. After optimization, the average was about 42,600 prints per knife, reducing knife usage by 204%, greatly saving on material costs.

Through this test and improvement, while ensuring product quality, we successfully reduced engraving knife usage, enhanced knife-changing efficiency, ensured product quality improvements, and achieved the expected goals. Additionally, our problem-solving and innovation capabilities have improved. Following the principle of continuously perfecting and improving product quality, in future work, we will continue to identify shortcomings from actual production and innovate accordingly.