Can the standardization of cigarette pack production be achieved in just four steps? Have you learned it?

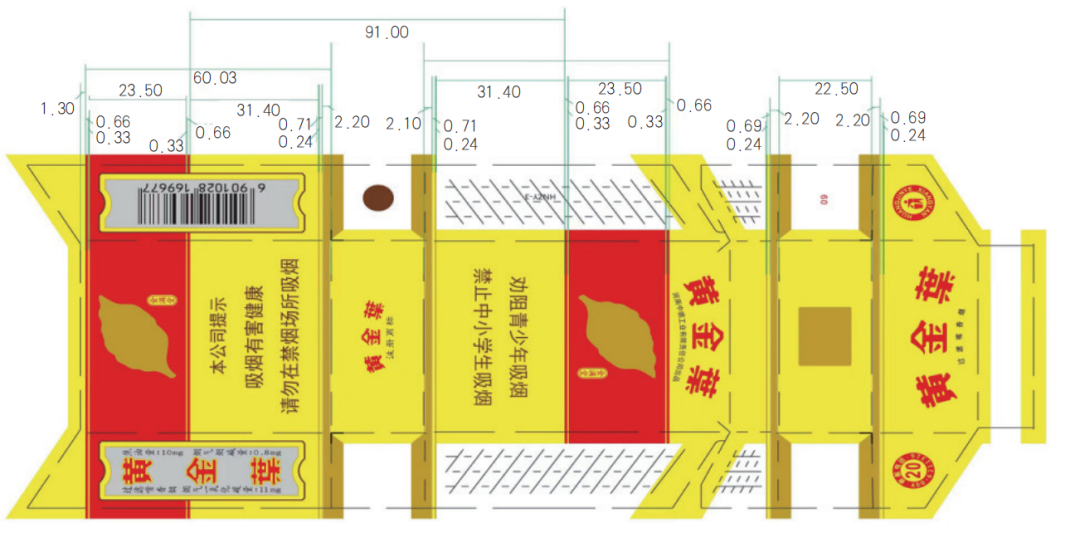

To better maintain the consistency of cigarette pack printing quality, operators need to carry out standardized operations according to operational procedures during production to avoid different personnel performing tasks based on personal preferences and habits. Achieving standardized operations requires having Standard Operating Procedures (SOPs), product process technical standards, and appropriate product quality inspection methods. Based on practical work experience, the author uses a product produced by the company-the "Golden Leaf" Jinmantang cigarette pack-as an example to explain how to implement standardized operations during the production process.Developing Standard Operating ProceduresStandard Operating Procedure (SOP) refers to a standardized description of the steps and requirements for a particular event in a uniform format, used to guide and regulate daily work. In simple terms, an SOP refines and optimizes the key control points within a procedure. From a management perspective, an SOP can shorten the learning time for new employees when dealing with unfamiliar and complex tasks, and following the steps can help avoid mistakes and oversights.SOPs are developed through continual practical experience and represent an optimized operational procedure design under current conditions. They generally have the following functions: first, saving operational time; second, reducing resource waste; third, achieving production stability. Their forms and usage methods are simple, intuitive, and easy to understand, making them effective tools for personnel to quickly obtain operational guidance.When establishing SOPs, several elements need to be considered: the first element is standards, the second is process, and the third is operability.01. StandardsThe standards on which the operational procedures are based mainly include behavior norms for operators, technical parameters of production and auxiliary equipment, process technical standards and quality requirements of the product, as well as other management requirements specified by the enterprise.02. ProcessThe process mainly includes the equipment preparation stage, auxiliary equipment installation and adjustment stage, equipment operation stage, and work completion stage. It focuses on key production elements such as "man, machine, material, method, environment, and measurement."03. OperabilityOperability mainly considers factors such as equipment characteristics, operator skill levels, production space environment, and the requirements of the product production process. The printing equipment used in our company for producing the "Golden Leaf" Jinmantang cigarette pack is a Bost ten-color gravure press with a sheet-cutting function.Developing Product Process Technical StandardsProduct process technical standards include product technical standards and production process standards. Product technical standards primarily refer to the standard information contained in reference samples issued by higher-level technical departments, such as product dimensions and shape, crease rigidity, appearance color, printing and foiling patterns and their positional relationships. This information needs to be interpreted and reproducible in production. Production process standards refer to the standards established during production according to product characteristics, equipment performance, and required materials; the two types of standards must be developed in conjunction.Detailed interpretation of product technical standards is necessary. The size and relative position of printed and foiled patterns, the dimensions and locations of die-cut and crease marks relative to the designs, must be precisely quantified. The types and specifications of base paper and metallized film, ink types and viscosities, printing color sequence, and equipment process technical parameters must all be clearly indicated in the production process standards to ensure that product quality achieves better consistency during production, meeting manufacturer quality standards and packaging machine adaptability requirements. The technical standards for the "Golden Leaf" Jinmantang cigarette pack are shown in Figure 1.

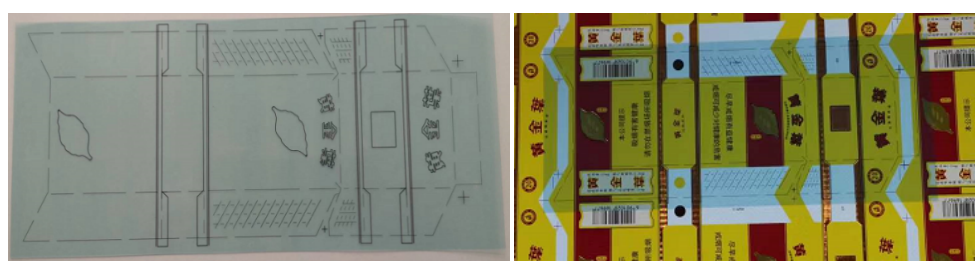

Figure 1 'Golden Leaf' Jinmantang Cigarette Pack Technical Standards (Unit: cm)Use Appropriate Inspection MethodsThe inspection methods here mainly refer to the physical inspection methods used during production. By thoroughly interpreting the product process technical standards and converting these standards into usable tools, production process guide cards can be created for foil stamping, embossing, and die-cutting procedures, and posted on the production machines. The guide cards should include the technical parameters that need to be controlled during each production step, as well as the process quality standard parameters for self-inspection, especially specifying the distances between different patterns, the distance from the pattern to the die-cut edge, and the stiffness requirements for each crease line.At the same time, film plates that match the standard sample's pattern content are produced (see Figure 2). The film plates have high transparency and are not easily deformed. During inspection, the film plate is placed above the product so that the patterns on the film and the product can be compared. This immediately reveals whether the pattern dimensions and relative positions on the product are accurate and whether deviations meet quality requirements. This method is very convenient for machine operators performing self-inspections during production, effectively improving both inspection speed and accuracy.

Figure 2 Detection of Film SheetConsolidation of Standardized Operation ResultsAfter a certain period of operation and inspection, the company has revised and improved areas that need enhancement in the standardized operation process. This has been compiled into the "SOP Standardized Operation Process Manual" and the "Process Technology Standards Manual" shown in Figure 3 to consolidate the results. These manuals are distributed to technical management personnel and machine operators, and training is provided to ensure they understand and master the manual's content. In actual production, operations are carried out according to the standards, thereby ensuring product quality consistency and uniformity.

Figure 3 Standard Operating Manual