Accurately controlling the mysteries of color | Achieving a qualitative leap in color management

In industries such as printing, packaging, textiles, and automobile manufacturing, color is not only the core of visual language, but also the embodiment of brand value. How to achieve color consistency from design to production? How to avoid cost waste caused by color difference? Today, we will talk about a full chain digital color management solution that empowers color with technology, allowing every work to accurately convey the brand soul!

1, Why has color management become a necessity in the industry?

Color errors not only affect product aesthetics, but may also lead to customer rejection, rework, and even a crisis of brand trust. Research has shown that consumers can make product purchase decisions in just 2 to 7 seconds. This time is called the first critical moment. Color plays an important role at this moment, and 60% of customer complaints stem from color deviation. Especially in multi link collaborative supply chains, the limitations of traditional visual assessment, such as lighting conditions and human perception differences, lead to frequent color difference issues.

Pain point hit:

The color of the design draft is inconsistent with that of the finished product

The color difference between different batches and suppliers is difficult to control

Lack of digital tools and reliance on subjective experience

2, Empowered by technology, solving color management problems

1. Hardware equipment: precise measurement, scientific quantification

Aiseli spectrophotometer: such as eXact2 portable spectrometer, supports multiple color systems (Lab *, ∆ Eab, etc.), can measure real color and surface color including specular reflection, analyze the influence of material and gloss on color, and the repeatability error is as low as 0.10 ∆ Eab813.

Standard light source box: such as Judge QC color light box, providing 5 types of light sources for visual evaluation, including optional LED, to achieve stable and consistent visual evaluation.

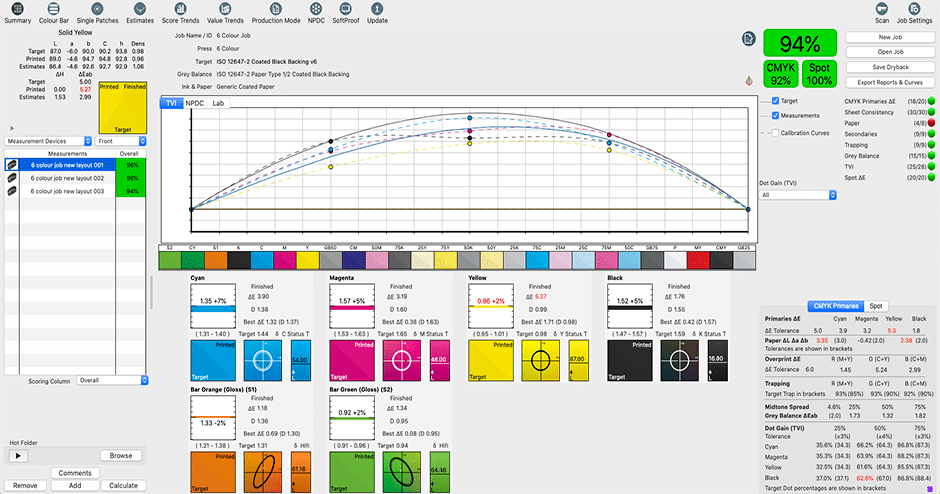

Machine closed-loop calibration+sample evaluation system: Through closed-loop control technology, automatic calibration of printing machines is achieved, reducing manual intervention and improving efficiency by more than 30%.

2. Software ecosystem: full process digital management

Color iQC: A supply chain collaboration platform that supports international buyer templates such as Walmart and Target, enabling cloud sharing of color difference data from raw materials to finished products, and generating quality inspection reports that meet customer requirements with just one click.

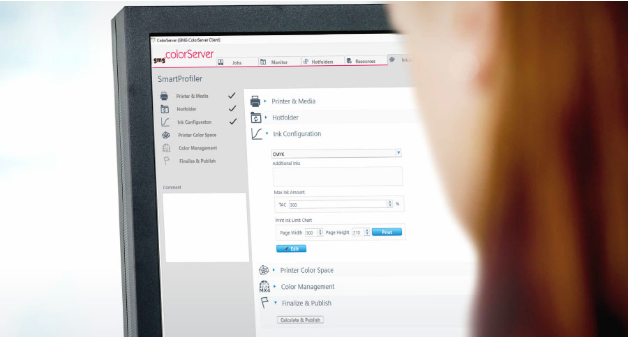

GMG ColorProof: a digital proofing software that accurately simulates printing effects, reduces traditional proofing costs, and supports cross device color consistency verification.

NetProfiler: an instrument performance monitoring tool that regularly verifies equipment accuracy to ensure comparability of measurement data from multiple locations worldwide

3. Service Support: Comprehensive Protection from Technology to Certification

G7/GMI/PSO certification training: International authoritative color standard certification helps enterprises improve their process standardization level.

Color laboratory construction: Provide one-stop services for equipment selection, process optimization, and personnel training, and establish an exclusive color management system for enterprises.

After sales guarantee: Maintenance network coverage, providing lifelong technical support such as instrument calibration, parts replacement, software upgrades, etc.

3, Success story: Technology helps brands soar

Ensure the best measurement results for printing, design, and branding

Coordinate production and brand expectations, produce according to measurable and achievable color standards

Reproduce accurate colors on various substrates, including liners, plastic films, adhesives, flexible packaging, laminates, labels, flexible plastic bags, upright bags, cardboard boxes, kraft paper, shrink wrap, cardboard, custom packaging, custom boxes, recyclable packaging, digital labels, etc

• Verify and report production quality

• Increase the output of printing machines

Reduce the need for approval on printing machines

Reduce typesetting adjustment time by 40%

Reduce ink, paper, and labor waste by 50%