Unveiling GMG Color Management: How to Make Every Shade of Color 'Obey'?

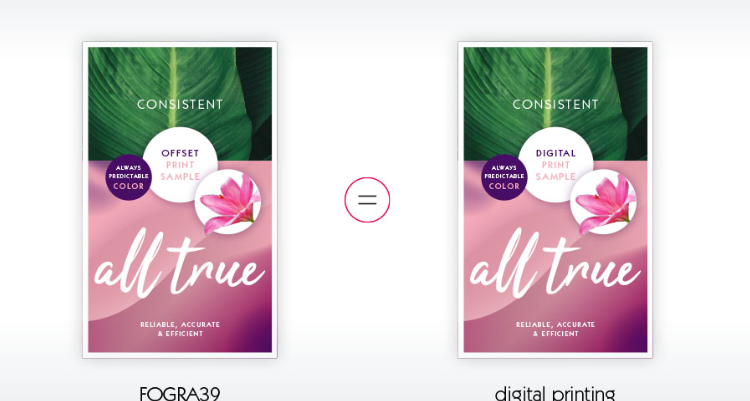

Today we are going to talk about a seemingly professional yet magical topic - color management. Whether it's a designer's computer screen, samples from a proofing center, prints from a printing house, or packaging boxes on supermarket shelves, the consistency of colors is always a headache. The star of today, GMG (a German color management giant), acts like a 'color translator' that allows seamless communication of colors between different devices!

1. GMG's 'core technology': ensuring colors no longer 'change their face'.

1. Four-dimensional color conversion engine

GMG's ColorServer module has a unique feature-a direct four-dimensional conversion from RGB or CMYK (for example, CMYK → CMYK). Unlike traditional ICC profile files, it can independently handle the black channel, avoiding the 'color bleeding' issue during color mixing. This means that black text in printed materials appears sharper, and the shadow areas have richer gradation.

2. Closed-loop calibration digital proofing system

GMG's ColorProof software supports 'self-correction' for printers. By using measuring instruments, it can automatically scan printed samples and adjust parameters to ensure that the output of each device (such as EPSON, HP, and Roland printers) is consistently stable. In simple terms, it allows the printer to learn to 'look in the mirror' and self-adjust to its best condition.

3. Spot colors can also be 'high fidelity'.

Special colors commonly found in packaging printing, such as gold and fluorescent colors, are difficult to simulate with traditional digital proofs. However, GMG's InkOptimizer can simulate even metallic sheen effects through its multi-ink combination algorithms. For example, COFCO's Mate brand metallic can printing achieved accurate color reproduction thanks to this technology.

2. GMG's 'Workflow Magic': From Design to Print, All in One Go

Imagine this: the designer finishes adjusting the poster on the computer and sends it directly to the printer, with colors matching perfectly - this is the networked color process built by GMG.

Designer side: ColorServer automatically converts RGB images to CMYK for printing while preserving highlight and shadow details, avoiding the 'grayish' tragedy.Printing factory side: ColorProof generates contract-level digital proofs, and the InkOptimizer module can optimize ink usage, reducing waste by 15%-30% (environmentally friendly and cost-effective).Quality control stage: The ProofControl tool automatically detects color differences in proofs, generating reports that even the boss can understand where rework is needed.

Three, Practical Case: Can color management be more 'hardcore'?

Application Cases in the Field of Metal Packaging PrintingAs a leading enterprise in China's metal packaging industry, COFCO Metase's products include beverage cans, milk powder cans, food cans, etc., which have very high requirements for color accuracy and spot color simulation. The application of GMG color management software at COFCO Metase is mainly reflected in the following:High-fidelity printing and spot color simulation: Through the GMG solution, COFCO Metase has achieved precise simulation of spot color printing, meeting customer demands for brand visual consistency. For example, in the transfer printing and tin printing processes, GMG ensures a high match between spot colors and four-color printing.Color uniformity across multiple production lines: GMG helps COFCO Metase achieve color standardization across different printing production lines, solving the color difference issues caused by equipment differences in traditional printing and improving production efficiency.Application Cases in the Digital Printing IndustryBeijing Shengtong has introduced HP Indigo 750 digital printing equipment, and combined it with GMG color management software to significantly enhance the color stability of digital printing:Offset paper color optimization: Through GMG's calibration of 120g offset paper, the color difference before and after using GMG was minimized, verifying GMG's effectiveness in digital printing.Quick proofing and cost control: GMG's closed-loop correction technology has shortened the proofing cycle and reduced material waste before printing, making it particularly suitable for short-run printing orders.Technical Certification and Industry RecognitionGMG solutions have passed multiple international technical certifications, including Fogra and PSO, and have accumulated over 120 international brand application cases worldwide. Remote proofing and cross-regional collaboration are used by multinational printing groups for coordinated production across multiple locations.