How to deal with dirty printing plates? Take a look at these two typical cases...

一连串的问号使人无从下手,甚至有些同志不耐烦,认为产品质量还可以,用不着太较真.

众所周知,要想提高操作水平,就要学会在日常工作中不断分析,解决问题,特别是疑难问题,坚决不能轻言放弃.

基于此种信 念,我们再次逐一检查墨辊,仔细调整靠版墨辊,串墨辊,印版,然而并没有发现明显异常.

后来,我们把重点转移到水路上,拆下计量辊,采用"打墨杠"的方法,发现靠版水辊对串水辊的压力只有不到2毫米的墨杠,压力明显不够,于是两端各加些压力,使墨杠达到7毫米.

再次开机后,故障消失了,印出来的品红网很干净,平服,墨色也基本保持稳定.

02 故障剖析

The balance of ink and water is not only the foundation of offset printing but also its challenge. According to my understanding, the key to ink-water balance lies in controlling the water. On one hand, it involves the proportion, temperature, and circulation cleanliness of the water; on the other hand, it requires correct adjustment of the damping system. Generally, the first aspect is almost static and does not change much, while the latter is dynamic, with many variable factors, making it difficult to master, which often results in dirty printing plates.

What exactly causes dirty plates?

Based on practical experience, I have conducted a simple analysis, roughly divided into: greasy dirty plates, dirty plates due to insufficient water, dirty plates caused by light pressure on the water roller, dirty plates due to water roller bouncing, and dirty plates due to poor water distribution by the roller, etc. It can be said that most are caused by improper adjustment of the water roller. Therefore, I will combine two typical cases I recently encountered to share some of my experiences.

Dirty plates caused by poor water distribution of the roller

01 Fault Phenomenon and Solutions

When printing the cover of the "Morality and Law" textbook, we noticed that the magenta plate showed a straight, cloth-like streaking dirt pattern, which was fairly evenly distributed. The entire design was almost like this from start to finish.

Increasing the water intentionally slightly improved the streaking but did not completely eliminate it. Obviously, the fundamental cause was not related to the water quantity. Since the cover design uses a pale blue color, and the blue and magenta are in full-screen halftone, printing is relatively difficult. After the press operator initially adjusted the ink-water rollers, the streaking phenomenon still did not improve at all. So everyone started to suspect other causes:

Could it be that the quality of alcohol-free damping solution is unstable?

Could it be that the ink roller has pitting?

Could it be that the ink roller is calcified?From the perspective of the ink system: Ink cannot form streaks or filaments of dirt simply through repeated movement and pulling by the fountain roller. From the perspective of the water system: During the printing process, if dirt occurs due to insufficient amount of water, it generally appears locally, starting from the gripper edge, while the tail end of the sheet is hardly affected. In this case, the issue can usually be resolved by appropriately increasing the water supply.Clearly, this malfunction is not merely due to insufficient water, but has more complex causes. To identify the reason, it is necessary to carefully analyze the water system transfer (as shown in the figure below).

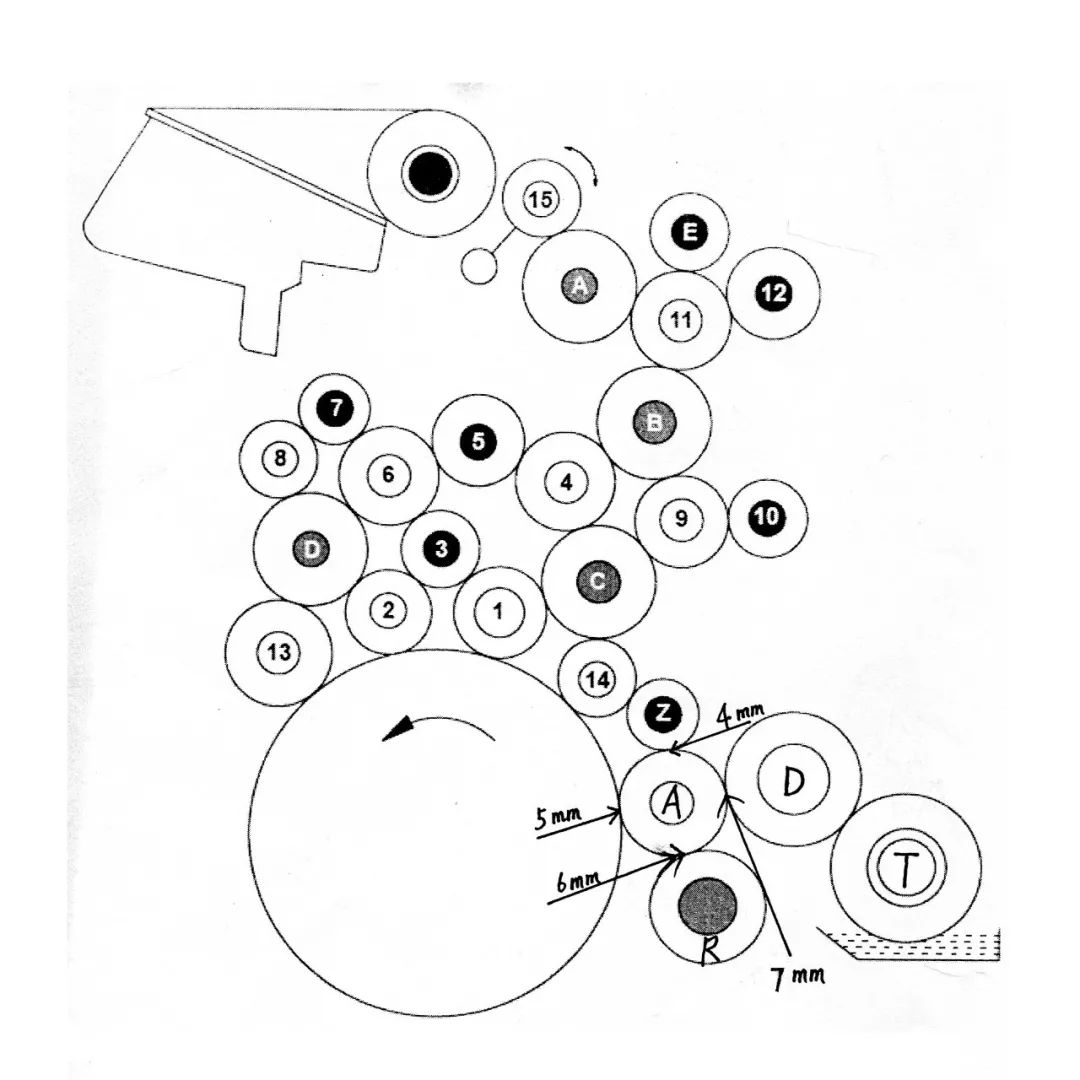

The fountain roll (T), metering roll (D), and plate-bearing water roll (A) all supply water to the printing plate in a straight and uniform manner, while only the oscillating water roll (R) moves back and forth in small amplitudes.

The key to the above malfunction lies in the fact that when the pressure between the plate-bearing water roll and the oscillating water roll is significantly low, the operation of the plate-bearing water roll almost relies on the rotation of the printing plate cylinder. This causes the water film on the surface of the plate to not be evenly distributed by the oscillating water roll, resulting in very regular dots in the printed image, which appear as shallow fabric-like streaks throughout, causing contamination.

Contaminated plates caused by water roll vibration

01 Malfunction Symptoms and Solutions

During a certain printing process, it was found that the magenta group would often inexplicably become contaminated around 10 centimeters from the gripper edge, as shown in the figure below.

After investigation, we found that this situation had been occurring for several days. We deliberately reduced the machine speed and increased the water volume, and the results were barely acceptable. However, operating the machine in such a precarious manner is not a long-term solution; the root cause must be identified as soon as possible.

After careful observation, we discovered noticeable wobbling in the axle seat of the inking roller of the color unit, initially suspecting that the pressure of the inking roller on the plate might be too high. We then stopped the machine for inspection, which showed normal readings.

Could it be that some fasteners were loose?

After checking, everything appeared normal.

Could the hydraulic cylinder support rod have loosened?

By manually pushing the cylinder support rod, we found it was indeed loose. Under normal operating conditions, the cylinder could not be moved back and forth with human force alone. This led us to conclude that the cylinder seal was leaking, preventing the inking roller axle seat from operating stably. We immediately replaced the cylinder, and the problem was resolved.

02 Fault Analysis

In the fault described above, the dirty plate occurred in the upper part of the gripper area. When the machine speed was reduced, the oscillation of the inking roller gradually decreased, and the dirty plate phenomenon improved. This is completely different from the dirty plate caused by insufficient water, which we often encounter.

The causes of water roller bouncing, besides cylinder air leakage, include many others: (1) Excessive pressure of the water roller on the printing plate;(2) Wear of the water roller bearings, resulting in wobbling;(3) Poor fit between the water roller shaft ends and the bearing seats, causing wobbling;(4) Loose or missing fastening screws;(5) Poor processing accuracy of the water roller, causing it to be out of round.In actual production, there are many causes for dirty printing plates, not necessarily due to insufficient water supply. If the operator mistakenly increases the water supply, it will inevitably cause ink-water imbalance, leading to a series of problems. Therefore, only by truly mastering the correct adjustment and use of the offset press water system can one truly control the key to ink-water balance and thereby print better products.