How can Classic Printing bring AI into the printing production?

At the turn of the year, with everything renewed, "Printing Manager" is specially launching the annual review feature "2025, Printing Industry, Please Answer." Previously, we revisited the "Keywords of the Year" (click here: What are the 2025 Printing Industry Keywords? Resilient development, anti-'involution', emotional consumption…). Next, we will focus on printing companies' annual "breakthrough actions," reporting on a series of moves and strategies by outstanding companies in 2025, as well as their plans and visions for 2026. We aim to highlight the companies' shining moments and explore the industry's development trends.

Against the backdrop of the printing industry's accelerated shift toward green, digital, intelligent, and integrated transformation, some printing companies have begun introducing artificial intelligence technology into specific production and management processes, exploring transformation paths driven by data to replace experience-based decision-making. Shandong Classic Printing Co., Ltd. (hereinafter referred to as Classic Printing) focuses on the goal of digital transformation and continuously promotes the application of AI in production, management, and R&D. These explorations have achieved phased results in improving efficiency and product quality and have received multiple recognitions at the national and provincial levels, providing an observable example for the industry.

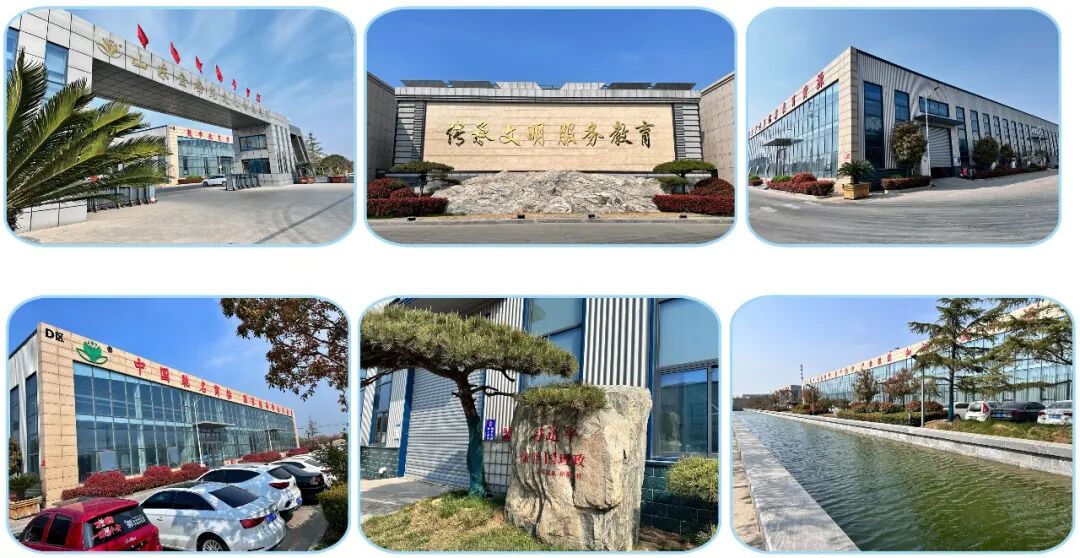

Exterior of the Classic Printing Factory

Classic Printing Factory Environment

Classic Printing Factory Environment

2025: Exploring AI-Enabled Digital Transformation

The year 2025 is a crucial period for advancing digital development at Classic Printing. To address long-standing challenges in the traditional printing industry, such as high reliance on experience-based decision-making, low production efficiency, and weak quality control, the company is adopting a data-driven strategy to promote the scaling of AI from localized pilots to full-process implementation. Focusing on core areas such as order management, production organization, quality inspection, and warehousing logistics, the company is gradually building a fully integrated intelligent operation system.

Classic Printing Production Workshop

Classic Printing Production Workshop

1. Core Technology Breakthroughs

On the technical level, Classic Printing has partnered with Inspur Group to explore the development of a multimodal large model tailored for the printing industry - the Smart Printing Large Model. This model is based on an open-source large model framework, enhanced with industry-specific knowledge, and can cover application scenarios such as intelligent Q&A, report generation, fault diagnosis, and quality inspection. It provides core technical support for the full-chain intelligent upgrade of enterprises. To further ensure model performance, the company continuously accumulates and organizes equipment operation data, process standards, defect images, sensor data, and MES and ERP business data during production practice, forming a large printing model corpus covering processes, equipment, quality, materials, design, and management. This corpus spans major production processes for both traditional offset printing and digital printing, providing data support for model iteration.

2. Full-Chain Printing Empowerment

On the production level, Classic Printing has implemented intelligent upgrades on over 40 production lines. Through digital twin virtual factories and AI technology, equipment status and production data can be visualized and managed, enabling real-time tracking of the entire book printing process, with automatic monitoring and alerts for production environment safety. After introducing AI scheduling into the MES system, order execution status can be tracked throughout the process, product pass rates and delivery efficiency have improved, and the average order delivery cycle has been reduced from 7 days to 5 days. In the logistics and warehousing segment, the AGV scheduling system automates material flow, increasing warehouse space utilization by 23%.

On the management level, Classic Printing has integrated production, inventory, and sales data to build a fully-featured digital management platform for the book printing industry. Leveraging AI and large-model intelligent analysis capabilities, the system can automatically generate outputs such as production efficiency, cost analysis, and market demand forecasts, providing data support for production planning and management decisions. In research and process optimization, the company continuously improves green printing processes, enhancing the adaptability and stability of raw materials like ink and paper, thereby better meeting the printing requirements of educational publications.

Classic Printing AI Integrated Printing Analysis Platform

Classic Printing AI Integrated Printing Analysis Platform

2026: From "Application Implementation" to "Continuous Optimization"

Building on existing explorations, Classic Printing plans to further deepen the application of AI in 2026, focusing on three main directions: technology iteration, scenario expansion, and ecosystem construction, driving the company from "intelligent production" to "smart services."

1. Technology Iteration and Upgrade

At the technical level, Classic Printing will focus on two cores: large model optimization and corpus expansion. For large models, the company will further enhance core capabilities such as multimodal interaction, process optimization, and fault diagnosis, enrich the knowledge base, and improve adaptability to complex scenarios. In terms of data, the company will continue to expand and upgrade corpus resources, gradually covering niche areas such as book covers and packaging printing, building a dynamically updated industry knowledge hub.

2. Scenario Innovation and Expansion

In response to current market demands for personalization, small batches, and fast delivery, Classic Printing, supported by the Smart Printing Large Model, will focus on promoting two core scenarios: intelligent scheduling and personalized design. In the intelligent scheduling phase, by building a dynamic system that integrates data such as order priority, equipment status, and material inventory, production connections will be optimized, improving efficiency for small batch orders and reducing waiting time. In the field of personalized design, by establishing an AI-assisted platform and integrating templates and process libraries, rapid requirement analysis and solution generation can be achieved, promoting closer coordination between design and production. Next, Classic Printing plans to drive deep linkage between the scheduling system and MES, consolidate category-specific algorithms in practice, and explore a service model centered on "personalized design and intelligent scheduling," expanding application scenarios for small and medium-sized enterprises.

3. Ecosystem Collaborative Construction

In terms of green development, Classic Printing, supported by large models and corpora, will use AI for energy management, further optimize parameters, reduce energy consumption, and promote environmental upgrades across the entire chain. At the industry collaboration level, the company plans to participate in building an AI technology sharing platform for the printing industry, open core resources to drive digital transformation for upstream and downstream enterprises, help establish an educational printing industry cluster, and promote broader application of related technological achievements.

Employees wearing VR devices

Digital Application Scenarios in Classic Printing

Digital Application Scenarios in Classic Printing

From building intelligent printing models and an industry corpus system to deepening AI applications around specific production and management scenarios, the practices of Classic Printing provide a reference path for traditional printing enterprises on how to embrace AI technology and advance digital transformation. As technological capabilities and data resources continue to improve, the value of AI in the printing industry still needs to be continuously tested and deepened in more real-world scenarios.