Attend the 2025 European Label Expo and witness new breakthroughs in flexographic printing technology!

PART.02

Flexographic PrintingFlexographic printing (including hybrid printing) is, besides digital printing, one of the most important exhibition focuses at the trade show. Each exhibitor showcased their latest technological innovations, including automated production, AI technology applications, online image and color control, as well as new achievements in plate-making technology and inks. Below, we will introduce them one by one.01SpandexAt the exhibition, Spandex presented several innovative products, including the AC series wide-web flexographic packaging production line, the S7 modular flexographic press, and the Label Modular 330 HD digital-flexo integrated press. Among them, the AC series wide-web flexographic packaging production line allows each standard base to be freely equipped with interchangeable units such as flexography, gravure, offset, screen printing, and even die-cutting, offering extremely high process flexibility; the S7 modular flexographic press is Spandex's classic intelligent modular press, now upgraded to the fifth generation; and the Label Modular 330 HD digital-flexo integrated press is a typical example of an integrated digital and flexographic solution, showcasing innovative achievements from cross-industry collaboration among equipment manufacturers.

Spander equipment attracted significant attention from visitors from various countries at the exhibition because it not only offers high-end, fully automated flexographic printing equipment but also similar devices that are easy to operate and adjust, leading to a large number of orders and potential customers. Spander focuses on product innovation and development and has a high market share in the domestic flexographic printing industry. Due to the stable quality of its equipment and excellent after-sales service, the repurchase rate of its equipment is high. Many well-known label printing companies in coastal areas are equipped with Spander devices, gradually replacing imported counterparts.02Weigang TechnologyAt the exhibition, Weigang Technology showcased its flagship product-the ZJR-350E high-end label flexographic printing machine. The equipment is equipped with 25 independently controlled servo motors for precise coordination, 8-color three-station die-cutting units, and can achieve ultra-high-speed stable operation at 150m/min. Each color unit allows front and back registration, with a registration accuracy of up to ±0.05mm. The plate cylinder is servo direct-driven, improving registration stability during acceleration and deceleration, and the plate change operation is quick and convenient with no maintenance costs required.

03

BotaiAt this exhibition, Botai globally launched the FF-X530 AI Intelligent 8-Color Flexographic Printing Press. This equipment achieves deep integration of algorithm-driven processes and hardware coordination in flexographic printing, allowing real-time monitoring of ink viscosity, temperature, substrate changes, and environmental conditions, and automatically adjusting key parameters to achieve high-speed, stable, and precise printing. It is also equipped with the AVT 100% print quality inspection system and X-Rite precise color management technology, enabling full-process online monitoring and automatic calibration, setting a new benchmark for high-quality flexographic printing.

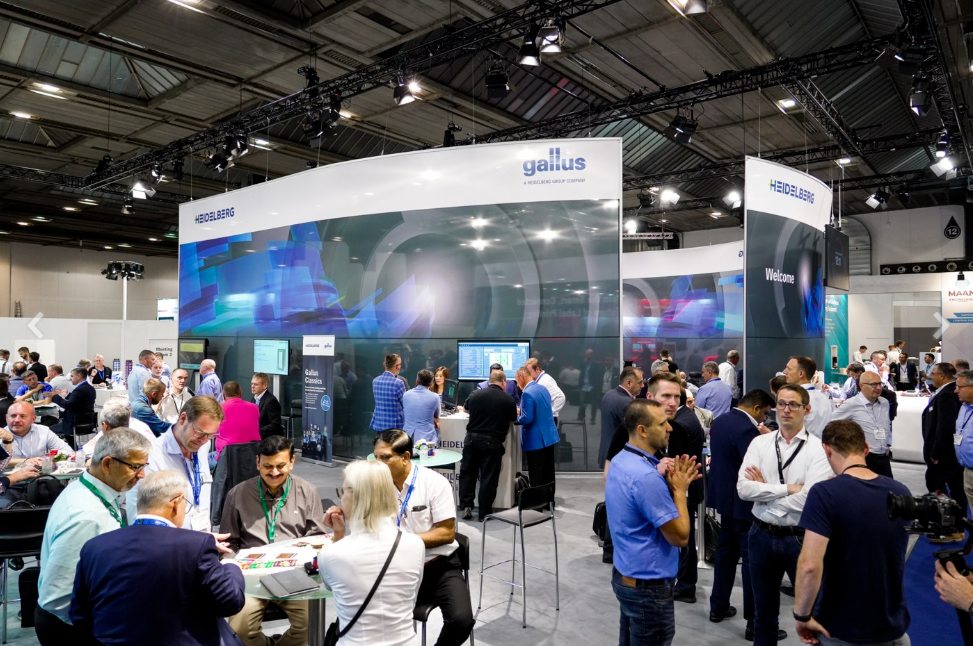

During discussions with Botai's leadership, it was learned that the purpose of this system developed by Botai is to cultivate talent for enterprises and align with the world's advanced management and technology. Currently, this system is in a semi-closed-loop state in automatic control, and Botai's goal is to achieve fully closed-loop quality control in a few years, realizing true automated production.04GallusAt this exhibition, Gallus launched two brand-new label printing machines: the Gallus Alpha digital printer and the Gallus Five hybrid printer. The Gallus Alpha digital printer is designed for enterprises seeking convenient and economical digital label production, with a speed of 65m/min and a high resolution of 1200×1200dpi. The Gallus Five hybrid printer is based on the existing Labelmaster platform, perfectly integrating digital technology with traditional technology, achieving a production speed of up to 100m/min and a resolution of 1200×1200dpi. It features a modular design and is equipped with inline post-print processing capabilities.

Gietars first entered the Chinese market around the year 2000, with its first flexographic printing press model being the Asoma-280, installed at the training center of Avery China. It was used to train personnel from China and Southeast Asia's label industry in flexographic printing technology, making a significant contribution to the promotion and popularization of flexographic printing. Some of the larger domestic label printing companies almost all have Gietars equipment, and these machines are still running well today, delivering excellent printing quality, serving as one of the main production machines for these companies.05NilpeterAt the exhibition, Nilpeter focused on showcasing the FA-26 flexographic printing press. This equipment made its European debut with a maximum width of 670mm and can be equipped with UV curing units and hot air dryers. It is used for producing various film packaging, labels, and cardboard products.

We observed the on-site demonstration of the FA-26 flexographic printing press and listened to a detailed introduction. The most important innovation is that each printing unit of the machine is equipped with two cameras, which acquire the printed images at any time during the printing process and randomly compare them with the samples. The Lab data changes of each color are recorded and stored in a database, which facilitates quality inspection in the subsequent stages. This represents an innovation in print quality control, shifting from density control to colorimetric control. It is a new development in the field of flexographic printing, and we look forward to this new technology gradually maturing, being widely applied, and further improving the quality of flexographic printing.06BOBSTAt the exhibition, BOBST mainly showcased application-oriented demonstrations. The BOBST FLEXJET module made its debut as the industry's first fully digital label solution. It can be seamlessly integrated into the DIGITALMASTER series platform and is equipped with multiple inline digital printing units, allowing converters to produce multi-layer labels entirely digitally. This fully integrated workflow enables complex operations such as multi-layer labels, adhesive face printing, and reverse side printing to be completed in a single pass.

In the promotion of new technologies and new processes, BOBST has always been at the forefront of the industry. The seven-color printing (wide color gamut printing) technology was first promoted by BOBST in China. BOBST is also one of the earliest advocates for comprehensive quality control, being among the first to introduce the concept of ΔE into the label printing industry, achieving very good application results.07Mark AndyAt the exhibition, Mark Andy showcased several products, including the Performance Series S9 flexographic press and the Evolution Series E5 flexographic press. The S9 flexographic press adopts an upward paper path design, offering two web widths of 560mm and 660mm, with a maximum printing speed of 305m/min. The E5 flexographic press is an expandable machine with a maximum production speed of 230m/min and web widths of 330mm and 430mm.Mark Andy was one of the first American companies to enter the Chinese printing market and one of the earliest equipment suppliers to introduce flexographic printing technology to China. Other companies entering the Chinese market around the same time included Primera and Yagafa. Mark Andy equipment is known for simple design and ease of operation, which are highly favored by users. The equipment displayed at this exhibition showed significant improvements in both structure and performance, especially in hybrid printing machines combining digital and flexographic printing, with leading printing effects and quality.08OMETAt the exhibition, OMET focused on introducing the XFLex K6 flexographic press, a device representing a new concept of modularity and a fully interchangeable platform, allowing printing companies to adjust the press configuration according to actual production needs. At the same time, it also launched the IUV interchange curing system, enabling seamless switching between mercury lamps and LED light sources.OMET's flexographic printing technology has developed rapidly in China and holds a high market share. With domestic factories, OMET performs well in after-sales service and the promotion of new technologies. Particularly in the practice of seven-color printing processes and hybrid printing combined with digital printing, OMET has set an example in the industry, achieving notable results.Above, we have briefly introduced the equipment of some exhibitors of flexographic and hybrid printing machines at the exhibition. Of course, other exhibitors such as Jiangxi Zhongjing, Hongyuan Digital, Zhejiang Hongseng, and Zhejiang Zhongte also showcased their innovative technologies, which will not be listed here one by one.In summary, each company has its own characteristics in technological innovation. In general: AI technology has gradually entered flexographic printing equipment, and the performance of the equipment depends on the support from system software (for example, some devices use software systems from Siemens). Traditional combination printing (including flexography, offset, screen printing, and cold stamping) has become a common process, while hybrid printing combining digital and flexographic printing is the future direction. Finally, it is hoped that domestic flexographic printing equipment manufacturers will continue to focus on technological innovation, providing higher-level flexographic equipment for label users in China and globally.