Dahong Packaging's 32nd Anniversary Celebration and Open Day Successfully Concluded

On November 6-7, 2025, the 32nd anniversary celebration and open day event of Zhejiang Dahong Packaging Technology Co., Ltd. (referred to as "Dahong Packaging") successfully concluded in Pinghu, Zhejiang. Through keynote speeches, on-site visits to the smart factory, and demonstrations of cutting-edge technologies, the event comprehensively showcased Dahong Packaging's achievements in digital transformation, smart equipment application, and the integration of innovation with tradition.

On the afternoon of the 6th, the event forum, themed 'Igniting a New Chapter · Passing the Torch · Building a Grand Vision Together,' brought together over 400 industry partners, technology experts, and strategic suppliers from around the world, with Xi Xiaoliang, General Manager of Zhejiang Dahong Packaging Technology Co., Ltd., serving as the host.

Xi Xiaoliang, General Manager of Zhejiang Dahong Packaging Technology Co., Ltd.

From pharmaceutical packaging to ACG (anime, comics, games) merchandise, Dahong's cross-industry journey has been both steady and precise. Where does this confidence come from? The answer lies in 32 years of manufacturing experience, in accurate market judgment, and, more importantly, in deep collaboration with top-tier partners.

The first partner to share was Gong Yugao from Koenig & Bauer Printing Machinery (Shanghai) Co., Ltd., who delivered a keynote on the theme "More Choices, Greater Flexibility, Higher Efficiency." Mr. Gong began by reviewing the company's development since entering the Chinese market, introduced its solid industry foundation, and highlighted its continuous innovation in printing technology. He also showcased Koenig & Bauer's layout in two main business areas: paper packaging and special technology applications, including digital printing, tinplate printing, and comprehensive packaging solutions. In addition, Mr. Gong emphasized the company's three core strategies: digitalization, modularization, and sustainability, and shared localized service initiatives in China such as establishing an employee service center and offering equipment upgrades and modifications, all aimed at providing customers with efficient, flexible, and environmentally friendly printing solutions.

Konig & Bauer Printing Machinery (Shanghai) Co., Ltd. - Gong Yugao

Wang Chengjie from Bost (Shanghai) Co., Ltd. shared "'In China, For China': Bost's New Product Development Journey." Mr. Wang highlighted the deep roots of the Swiss family business and the achievements of its localization strategy 'In China, For China.' As a Swiss family enterprise, Bost's China R&D department has had more than 30 professional engineers since its establishment in 2006, focusing on showcasing core products developed specifically for the Chinese market, such as die-cutting machines. Through the successful example of the 'Da Hong' project, the company demonstrated its strong local R&D capabilities and rigorous testing processes. Mr. Wang emphasized that Bost connects the industrial chain to provide customers with digital, automated, and sustainable packaging solutions and expressed the company's determination to continue deepening its presence in the Chinese market.

博斯特(上海)有限公司 王呈杰

Zhang Zhao from Lingyun Guang Technology Co., Ltd. presented "From Entry to Exit: Full-Chain Quality Control Solutions for Color Box Printing Factories." Mr. Zhang shared the company's intelligent vision solutions centered on a 'comprehensive quality program.' He emphasized that the company addresses industry pain points such as high standards and low profit margins by deeply integrating AI technology throughout the entire printing process, launching a series of products and solutions including prepress proofing, online quality inspection for offset printing, and compound line inspection machines. He also mentioned the development of next-generation products focusing on improved computing power, optimized defect detection, and case studies of implementing intelligent factory solutions. These solutions aim to eliminate batch defects from the source, achieve closed-loop quality management through data connectivity, and ultimately help printing companies reduce costs, enhance efficiency, and achieve transformation toward intelligent and digital operations.

Lingyun Guang Technology Co., Ltd. Zhang Zhao

Wang Ning from Tangshan Yuanchuang Automation Technology Co., Ltd. presented "Providing More Efficient, Safe, and Convenient Printing and Packaging Automation Equipment from the Customer's Perspective." Mr. Wang reviewed the company's development history, from the launch of the first fully automatic card waste removal machine in 2007 to the implementation of innovative products such as the integrated production line for playing card sorting without cutting angle and high-speed waste removal machines. The company has continuously focused on the field of automation, highlighting key products such as the fully automatic connected waste removal machine. It is committed to helping customers significantly save labor, improve production efficiency, and reduce defect rates through automation solutions, demonstrating Yuanchuang's strong expertise as a specialist in printing automation.

Tangshan Yuanchuang Automation Technology Co., Ltd. Wang Ning

Yang Yunfei from Shanghai Gaobang Printing Materials Co., Ltd. delivered a keynote speech titled "Building an Efficient, Innovative, and Green Printing System Together with High-Quality Stability," sharing the advantages of printing stability and the company's service philosophy from the perspective of a material supplier. Mr. Yang shared the company's concept of building a stable, efficient, and green material system, with technology research and development and intelligent manufacturing at its core. The company emphasizes independent R&D from the perspective of fundamental molecular structures, ensures product consistency through closed-loop intelligent manufacturing management, and showcased a mature product line covering various areas, including offset and UV printing. The company is committed to establishing deep collaborative partnerships with customers, jointly addressing the diverse challenges in the market concerning quality, efficiency, and environmental protection, building an efficient, green, and innovative industry ecosystem, and promoting the stable and innovative development of the printing and packaging industry.

Shanghai Gaobang Printing Materials Co., Ltd. - Yang Yunfei

Shen Wei from Suzhou Kede Education Technology Co., Ltd. presented to everyone on "Long-termism, Joining Hands with Dahong, Achieving Together." As China's first listed offset ink company, Coswood holds many industry "firsts," including acquiring a century-old European ink company and leading in domestic production, sales, and export of sheetfed offset inks. Its business covers a wide range of printing needs. The company has been deeply engaged in the industry for many years, evolving from early product optimization to its current stage of high-quality development, always focusing on environmental protection, innovation, and customer value. It has launched a full range of specialty products, including full-process maintenance inks, antibacterial low-odor inks, and high-end scented inks. At the same time, through its nationwide color-matching centers and technical service network, the company emphasizes front-end technical exchanges and rapid response services to help printing enterprises control costs and enhance value, aiming to become a strategic partner that supports the continuous development of outstanding companies like Dahong Packaging.

Suzhou Kede Education Technology Co., Ltd. - Shen Wei

Suzhou Kede Education Technology Co., Ltd. - Shen Wei

Shen Lin from Shenzhen Yinzhihulian Information Technology Co., Ltd. delivered a keynote speech titled "What Has Dahong Packaging Done Right in Building a Smart Digital Factory?", focusing on the digital transformation of the printing and packaging industry and the application of AI technology. As the full-system service provider for Dahong Packaging, Mr. Shen shared how the company built a digital system centered on ERP, coordinating four major systems: ERP, MES, SCADA, and AGV/WMS automated warehousing, to support exponential business growth. Mr. Shen stated that digitalization is an upgrade to the business model and a source of profit growth, while AI is the core direction of transformation. He also showcased an AI system with human-computer interaction, intelligent order processing, and process automation functions, offering full-scenario adaptability. Additionally, they launched tiered service solutions customized for large clients and simplified for small and medium-sized enterprises, ensuring implementation effectiveness through professional teams and extensive case studies. This helps clients achieve optimal control over costs, delivery times, and quality, thereby gaining sustainable market competitiveness and growth momentum.

Shenzhen Yinzhi Internet Information Technology Co., Ltd. - Shen Lin

He Ronghua from Shenzhen Tongren Yiyou Management Consulting Co., Ltd. presented "The Path to Inheritance and High-Quality Development of Printing Enterprises." President He focused on the inheritance and high-quality development of enterprises, emphasizing that in the context of industrial migration and intensified market competition, inheritors of printing businesses and their teams need to possess three core capabilities: industry insight, strategic planning, and business management. She highlighted the importance of grasping industry trends and achieving high-quality development through four types of growth. The core logic is to convey entrepreneurial spirit and team capabilities, drive growth through revenue, cost, and cash flow, and solidify the management foundation through standardization and other measures.

Relying on four main business segments-management consulting, talent incubation, and others-the company provides distinctive services through quantitative benchmarking and qualitative assessment to help clients increase performance, having generated a cumulative profit of over 100 million yuan, with services covering multiple regions.

Shenzhen Tongren Yiyou Management Consulting Co., Ltd. - He Ronghua

Finally, the forum concluded with a keynote speech titled "Holding Hands, Growing Old Together" by Xi Xiaoliang, General Manager of Zhejiang Dahong Packaging Technology Co., Ltd. Drawing on his personal experience of growing from a pilot to a successor-taking over the company in 2018 and leading it from 50 million yuan in sales to a scale of 200 million yuan by 2024-Xi shared practical insights. His core message centered on "business succession and second-generation leadership" and illustrated the process with a vivid logic: 'First, bow to the heavens and earth (self-improvement); second, bow to the parents (gain their approval); third, bow to each other as a couple (take charge of the business); after the rites, innovate.' He explained that second-generation successors need to proactively learn production techniques and management, resist ineffective socializing and capital temptations, and take responsibility courageously. They also need to communicate actively with their parents, maintain an equal relationship, set clear management boundaries, familiarize themselves with the company's operational logic in the workshop, improve organizational structures and processes, and be bold in trying new things. Additionally, he shared his practice of exploring new business directions such as e-commerce on top of the core printing business, emphasizing that second-generation leaders should combine inheritance and entrepreneurship, leveraging technology, content, and innovative approaches to achieve new breakthroughs on the shoulders of giants. Xi concluded by sincerely thanking his family, team, peers, and supplier partners for their support.

The partners' sharing at the Open Day Forum decoded Dahong Packaging's solid strength in continuously expanding into new areas. It not only showcased the company's firm steps from automation to intelligence but also conveyed the determination and vision to collaboratively create with industry chain partners and empower high-quality industry development through technology.

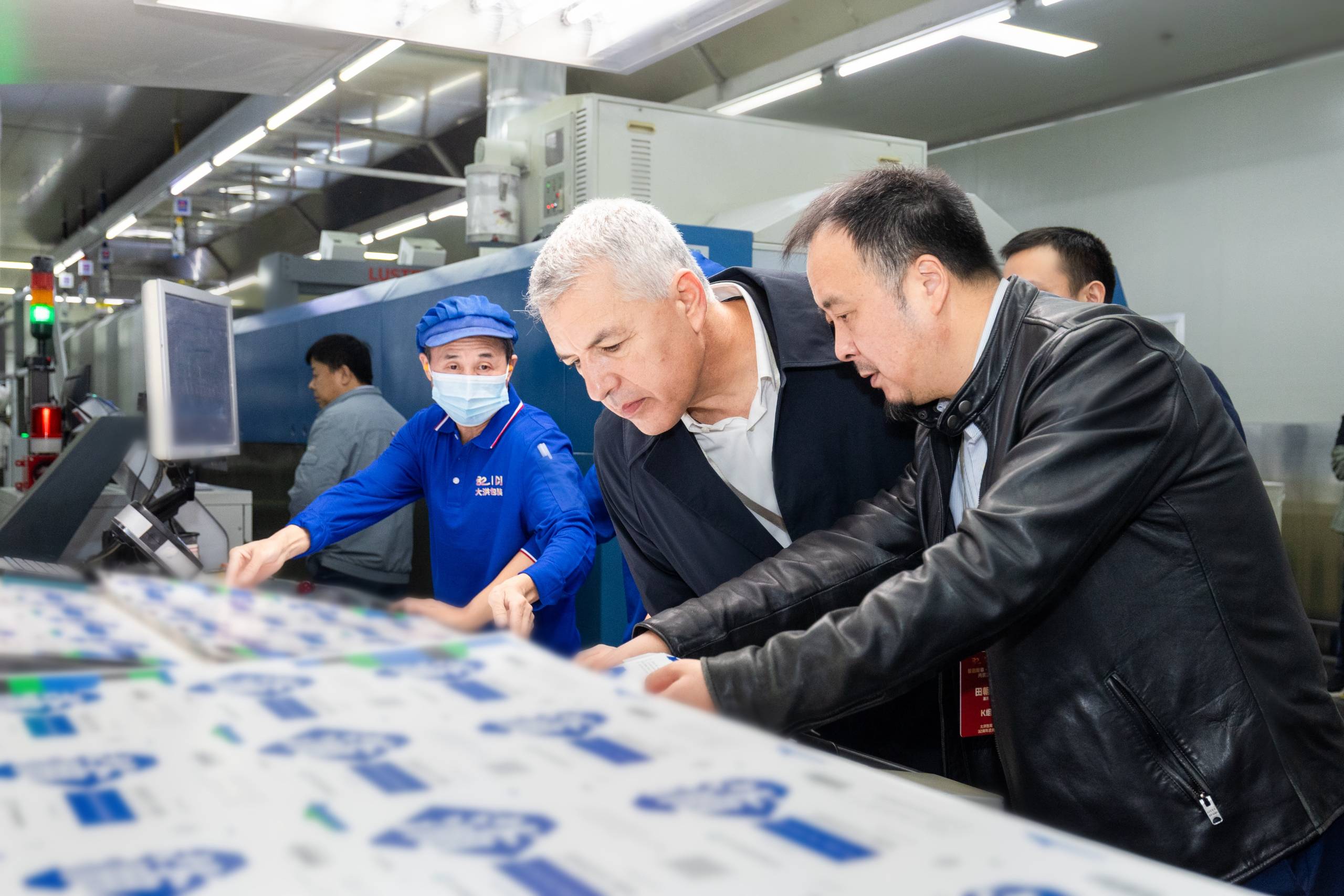

On the morning of the 7th, several industry partners visited Dahong Packaging Factory together for an in-depth tour focused on 'intelligent manufacturing.' Guided by the staff, the group followed the complete production line from 'coding-printing-post-pressing-intelligent warehouse.' From precise and efficient automated production equipment and standardized operating procedures to an AI-driven digital management system, every step showcased the ultimate pursuit of quality. The tour concluded at the intelligent warehouse, where everyone marveled as finished products were precisely grabbed by robotic arms, seamlessly transferred via AGV carts, and finally stored in the automated warehouse. This seamlessly connected 'lights-out' production line not only vividly demonstrates Dahong Packaging's digital intelligence transformation but also allows each partner to directly experience its full-process digital management capabilities, from order receipt to delivery.

The 32nd Anniversary Celebration of Dahong Packaging and Customer Open Day concluded successfully. Through a two-day themed forum and in-depth visits to intelligent factories, the event showcased the company's 32 years of solid experience and innovative breakthroughs in the field of packaging manufacturing. Under the theme of 'Igniting a New Chapter · Passing the Torch · Building a Grand Blueprint Together,' the event brought together industry elites from around the world to witness Dahong Packaging's outstanding achievements in digital transformation, intelligent manufacturing, and generational succession.

From intelligent printing equipment and full-chain quality control to automated post-press solutions, from material innovation to smart factory system integration, Dahong Packaging, together with high-quality partners in the industry chain, has built an efficient and collaborative innovation ecosystem. This not only demonstrates the company's firm steps from automation toward intelligence but also highlights the new generation of managers embracing change with openness and leading development with innovative thinking, setting a new benchmark for high-quality development in the industry.