Centennial persistence in the digital age: How can this German company lead the market in the offset printing industry?

At the highly anticipated 11th Beijing International Printing Technology Exhibition CHINA PRIMT 2025, Manroland Flat Printing System Co., Ltd. (hereinafter referred to as Manroland) shone brightly with its new flagship model ROLAND 700 EVOLUTION Excellent Edition printing machine under the theme of "staying true to its original intention and confirming the future", attracting countless attention.

Heike Weber, Sales Manager of Roland Asia Pacific

Heike Weber, Sales Manager of Roland Asia Pacific

At the exhibition site, a reporter from "Printing Manager" had the opportunity to interview Heike Weber, the sales manager of Roland in the Asia Pacific region. She elaborated on Roland's strategic layout and development direction in the global and Chinese markets, as well as her judgment and thinking on the global market environment and future industry trends. Let's follow her story and open the innovative chapter belonging to Roland, witnessing the touching story of inheritance and innovation.

Original intention remains unchanged, exploring market potential

Original intention remains unchanged, exploring market potential

In 1871, in the famous city of Offenbach on the banks of the Main River in Germany, Roland was quietly born. Over 150 years have passed, and Roland has gradually developed into one of the world's oldest printing machine manufacturers, occupying a leading position in the field of flat printing. Why does Roland always focus on the offset printing track? What is the current global layout?

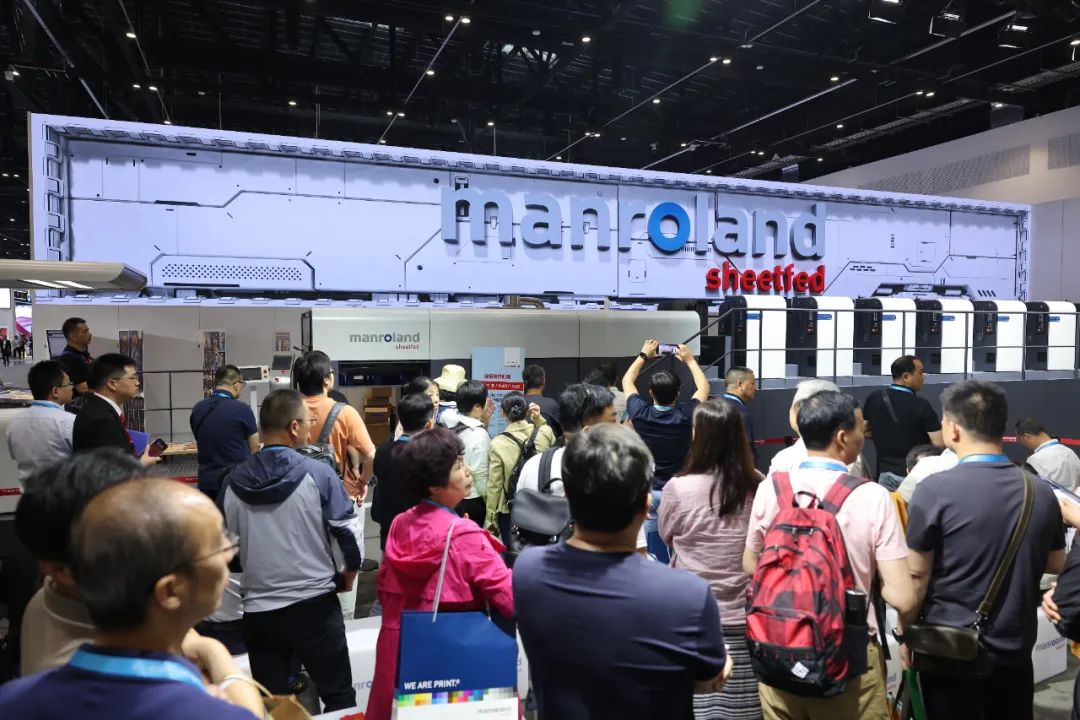

Manroland booth at the 11th Beijing International Printing Technology Exhibition

Manroland booth at the 11th Beijing International Printing Technology Exhibition

Heike Weber's answer is: "Offset printing technology continues to iterate and update, with excellent printing quality that can meet customers' needs for high-quality printed products. Even in today's rapidly developing digital printing technology, offset printing still maintains its unique advantages, especially in long plate printing brushes and high-quality image output. Offset printing's position is irreplaceable." As a leader in the offset printing field, Roland has been committed to promoting the development and innovation of offset printing technology and providing advanced printing solutions for global customers.

Looking at the global market, the Asia Pacific region has developed rapidly in recent years, with market demand gradually increasing. Among them, China is particularly important for Roland, as it is the world's largest market with enormous development potential. Our business in the Chinese market maintains an annual growth rate of 30% to 40%. Manroland attaches great importance to interaction and communication with Chinese customers, and has established long-term partnerships with many excellent printing companies. Manroland entered the Chinese market in the 1970s, has been deeply involved for decades, accumulated profound market experience, and has a deeper understanding of the needs of Chinese customers. Manroland Global attaches great importance to close ties and effective cooperation with its Chinese subsidiary, and will listen to the voice of the Chinese market in a timely manner, making quick feedback and adjustments

Heike Weber pointed out, "Currently, the competition in the Asia Pacific region, especially in China's printing industry, is fierce, and companies generally face key challenges in reducing costs and improving efficiency. At the same time, differentiation ability is also an important strategy for companies to build competitive advantages. We hope to stand together with Chinese printing companies, achieve mutual success, and achieve win-win results

Scene of audience visit at the exhibition site

Based on the market, focus on achieving excellence

Based on the market, focus on achieving excellence

The market is constantly changing, only focus and excellence can stand undefeated. Manroland is well aware that in this rapidly changing market environment, only by constantly moving forward and continuously launching cutting-edge innovative products and solutions can we win the trust and support of our customers.

In response to the market's demand for high efficiency, personalization, and other aspects, Roland has specially launched a customized model of ULTRAMA based on the globally popular ROLAND 700 EVOLUTION Excellence Edition printing press, which is also one of the highlights of our exhibition. "According to Heike Weber, it can provide the maximum range of process applications, including water-based polishing, UV polishing, special coatings, or opaque white ink, combined with OnePass © One time paper feeding technology integrates multiple finishing processes into a single feeding process, helping customers significantly improve efficiency while reducing costs and achieving sustained growth.

At the same time, ULTRA customized models have extremely high flexibility, allowing for the arbitrary combination of different modules according to personalized customer needs, similar to the combination of multi-color machines, polishing machines, and hot stamping machines, which can greatly save the time required for preparing live parts and switching between different devices. For example, in general, printing companies complete the post printing efficiency enhancement process such as polishing separately after all printing units are completed. The ULTRAMA customized model can place the upper ring joint between two printing units, which not only improves efficiency but also meets various process requirements in one paper feed

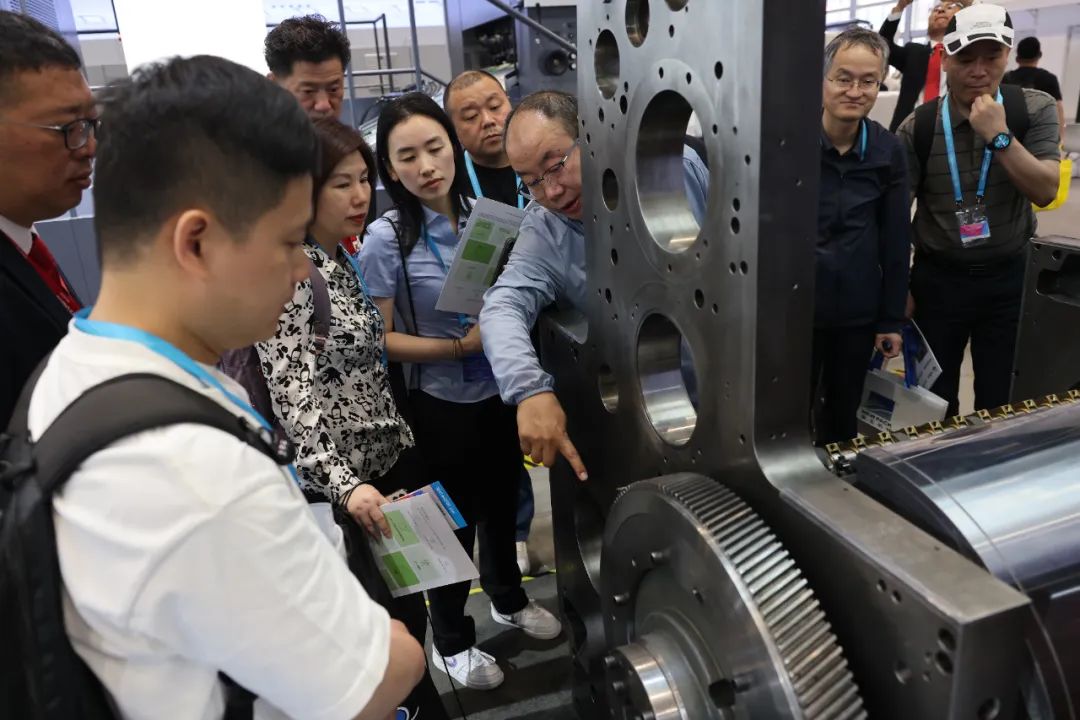

exhibition scene

exhibition scene

Heike Weber introduced that currently, ULTRA customized models are particularly popular in the Asian region, especially in the Chinese market, meeting the personalized needs for exquisite packaging in fields such as tobacco, alcohol, and cosmetics. This helps printing companies reduce costs and increase efficiency while improving product added value and market competitiveness.

In addition to creating high-quality innovative products, Roland always adheres to the service concept of "localization", serving customers and getting close to them with a localized team. In order to enable the operators of printing companies to have a better understanding of Roland's equipment and maximize equipment efficiency, we have set up training centers in Germany, China, and other regions. Currently, the training center in Shenzhen, China provides training almost every two months, and companies from nearby countries and regions can also participate in the training nearby. At the same time, Roland has also launched the Gold Captain series training activities to help printing companies cultivate technical talents

In addition, Roland has organized and participated in industry activities in various regions where its subsidiaries are located worldwide, strengthening interaction and collaboration with industry associations, relevant universities, and industry media to quickly grasp market demand and develop localized business strategies and solutions.

Embrace trends and lead the future of the industry

Embrace trends and lead the future of the industry

Undoubtedly, the future belongs to those enterprises that can take advantage of the trend and accurately grasp the development of the industry. Manroland not only focuses on current market demand, but is also committed to anticipating future trends. Through continuous technological research and market research, it always stays at the forefront of the industry. We deeply feel the urgent needs of Chinese customers for printing quality, printing efficiency, automation, and digital transformation and upgrading

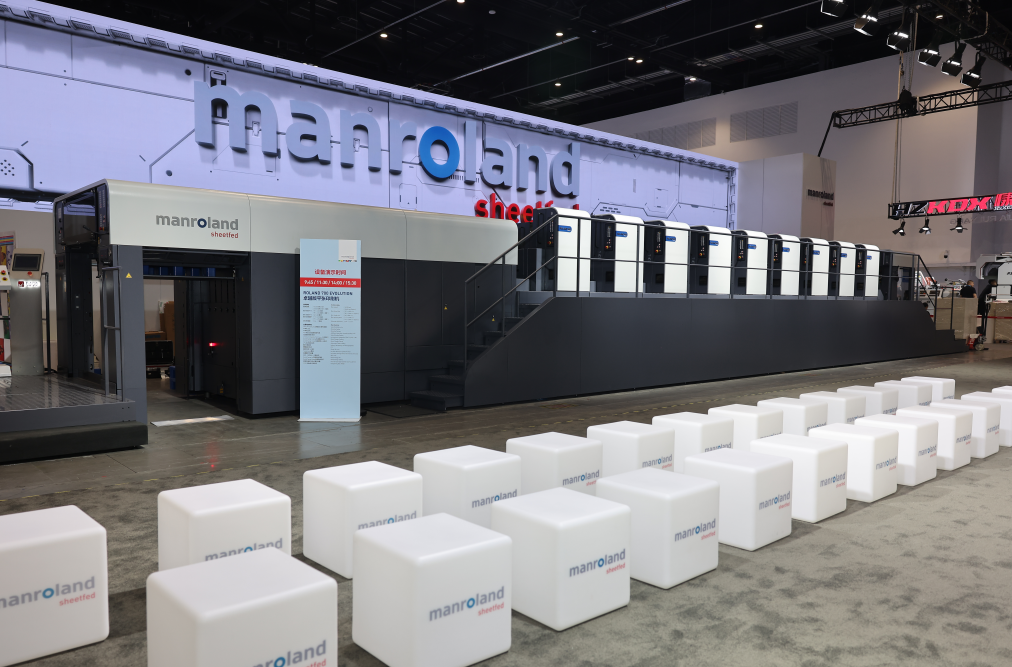

ROLAND 700 EVOLUTION Excellence Edition Printing Machine

ROLAND 700 EVOLUTION Excellence Edition Printing Machine

The all-new flagship model ROLAND 700 EVOLUTION of Manroland exhibited at this exhibition has a central console controlled by a touch screen, equipped with multiple automation technologies such as fast conversion device, fully automatic synchronous plate changing, register control, automatic cleaning, and three ink flow system, greatly improving production efficiency. In addition, in order to meet the demand of packaging printing enterprises for large format printing, Roland has also launched the highly automated 1.45 meter format printing machine ROLAND 900 EVOLUTION, as well as the 1.87-meter format ROLAND 900 XXL double-sided printing machine, with a printing speed of up to 16500 sheets per hour.

In the future, we will also assist printing companies in further optimizing and upgrading their existing equipment, while making new breakthroughs in production lines. We believe this will bring more surprises and expectations to everyone, "said Heike Weber with emotion.

exhibition scene

exhibition scene

In the face of the global trend of sustainable development and environmental protection, Manroland has provided corresponding solutions in equipment design, energy conservation and emission reduction. At the same time, it has also developed a series of environmentally friendly printing materials, such as Magicpix's environmentally friendly high-speed rubber blanket, car wash water, as well as printcom's Pudekeng series fountain fluid, environmentally friendly water-based varnish and engine oil, to help enterprises achieve low and alcohol free printing, greatly reducing VOCs emissions and making it safer and more environmentally friendly. For the research and development of each consumable product, we will repeatedly test it on Roland's equipment to ensure that the supporting products can better meet the needs of our customers and work together with Indian companies to move towards a green future

In the endless journey of exploration, Roland not only adapts to change, but also leads it; Not only embracing trends, but also shaping the future. From equipment to consumables, from hardware to software, Roland is constantly exploring and experimenting, making every printing a creation of art. Focus, breakthrough, and excellence are their creed, and they are also the most wonderful interpretation of Roland's story.